1/8

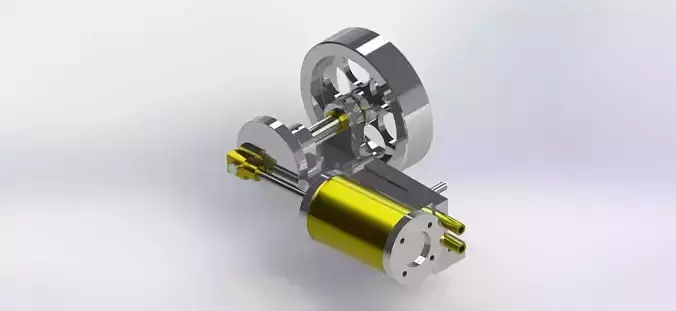

Creating a simple 1-cylinder oscillating steam engine involves designing a basic model with a cylinder, a piston, an oscillating mechanism, and a flywheel. Here's a step-by-step guide to help you understand how to create a basic representation:

Components:

Cylinder:

Create a vertical or horizontal cylinder, which is the main housing for the piston and where steam will act.Piston:

Model a piston that fits inside the cylinder and moves back and forth due to the pressure of steam.Oscillating Mechanism:

Design an oscillating mechanism to allow the cylinder to pivot back and forth. This mechanism is often a central shaft with arms connected to the cylinder.Crankshaft or Central Shaft:

Create a rotating shaft connected to the oscillating mechanism. The oscillating motion of the cylinder will be converted into rotary motion through this shaft.Connecting Rod:

Model a connecting rod that connects the piston to the oscillating mechanism, transmitting the piston's motion to the rotary motion of the central shaft.Flywheel:

Design a flywheel connected to the central shaft. The flywheel stores rotational energy and provides smooth operation.Working:

Steam Inlet:

Steam is admitted into one end of the cylinder through a port.Power Stroke:

Steam enters the cylinder, pushing the piston and causing the cylinder to pivot. This is the power stroke.Oscillation and Rotary Motion:

The cylinder pivots due to the oscillating mechanism, and this pivoting motion is transmitted to the central shaft, converting it into rotary motion.Flywheel's Role:

The flywheel helps store energy and smooth out the engine's rotation by providing rotational inertia.Exhaust Stroke:

The used steam is expelled from the cylinder.Piston Return:

The momentum of the flywheel and the action of the connecting rod return the piston to its original position, ready for the next cycle.Steam Switch:

Steam is then admitted to the other end of the cylinder, and the cycle repeats in the opposite direction, ensuring continuous oscillating and rotary motion.Creating a 3D model of this engine involves using CAD (Computer-Aided Design) software to design and simulate the movement of the components accurately. Paying attention to the dimensions, material properties, and assembly of components is crucial for a functional representation of the steam engine.

REVIEWS & COMMENTS

accuracy, and usability.