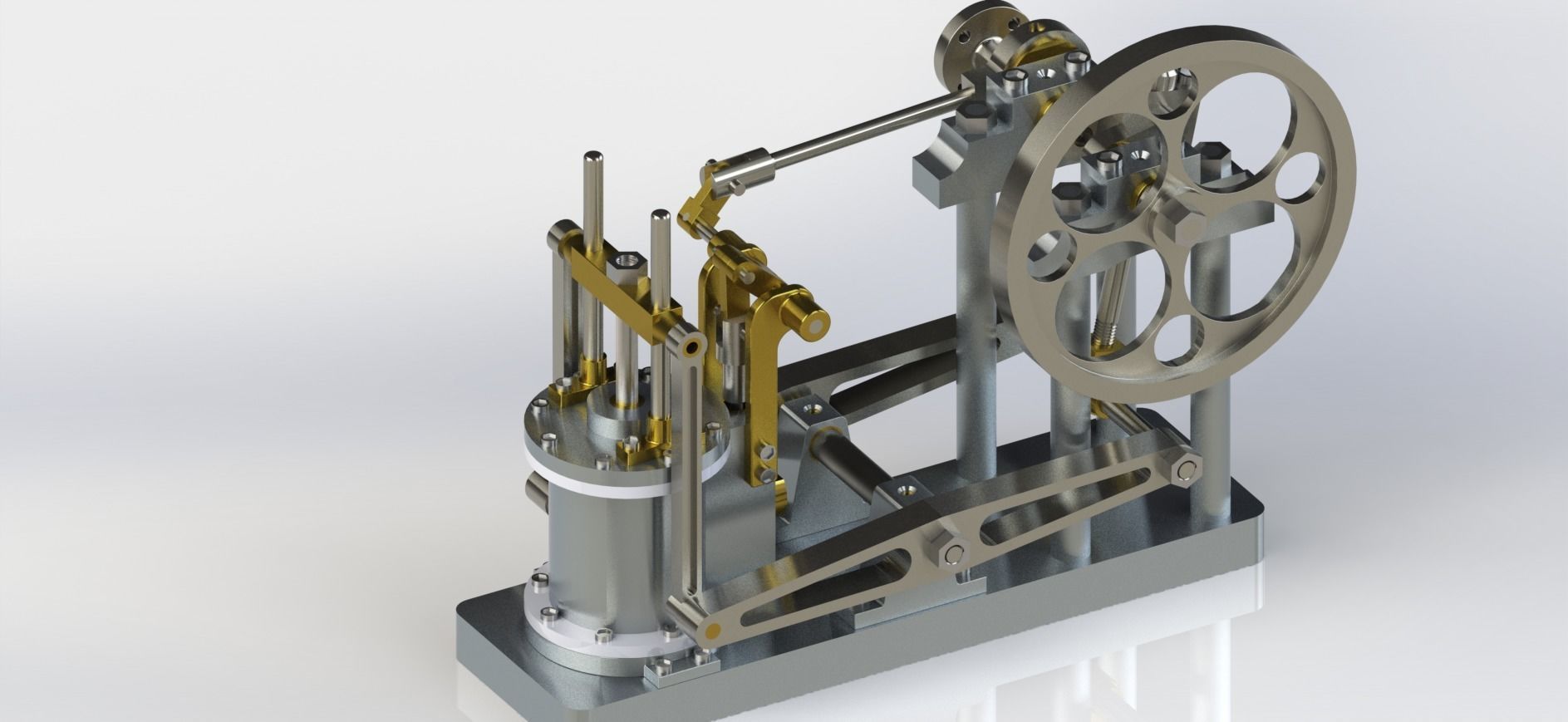

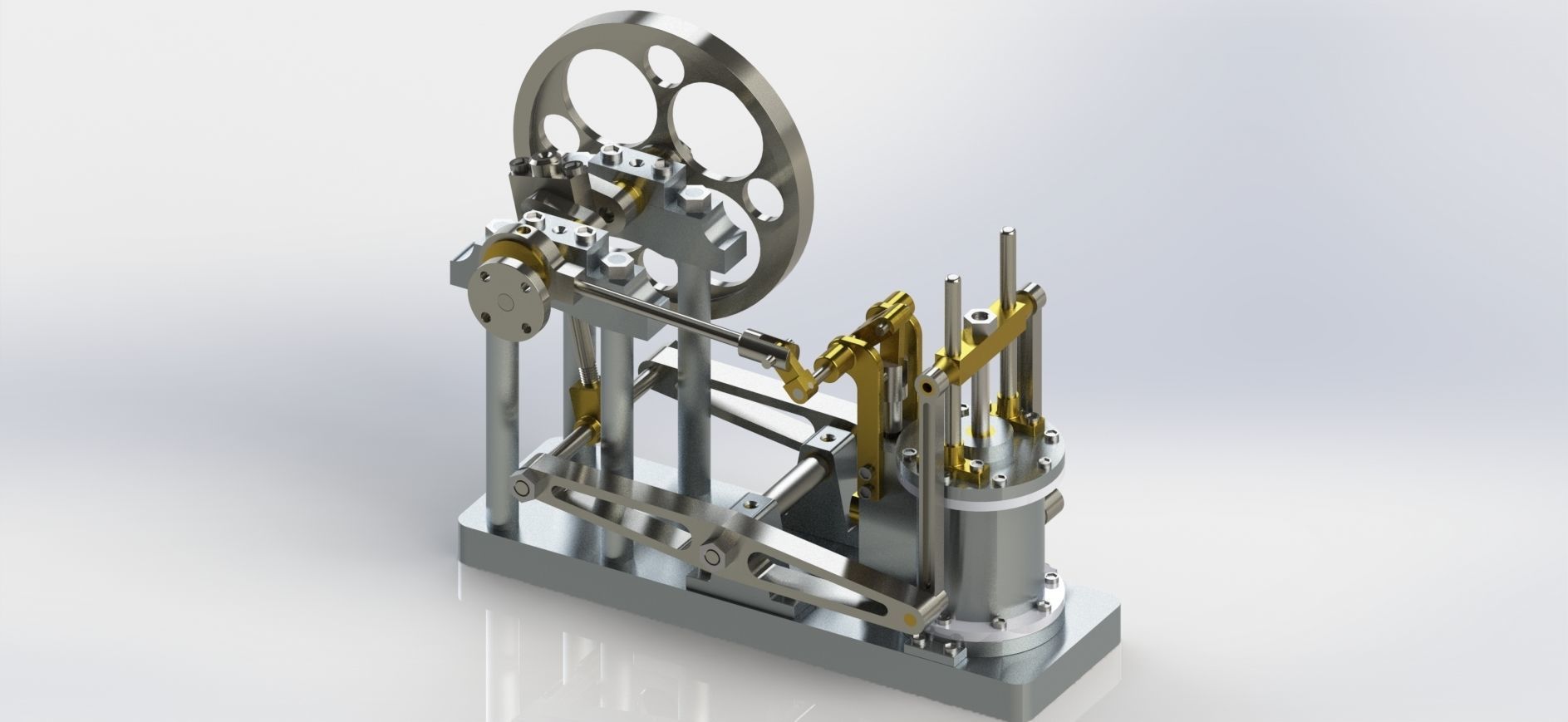

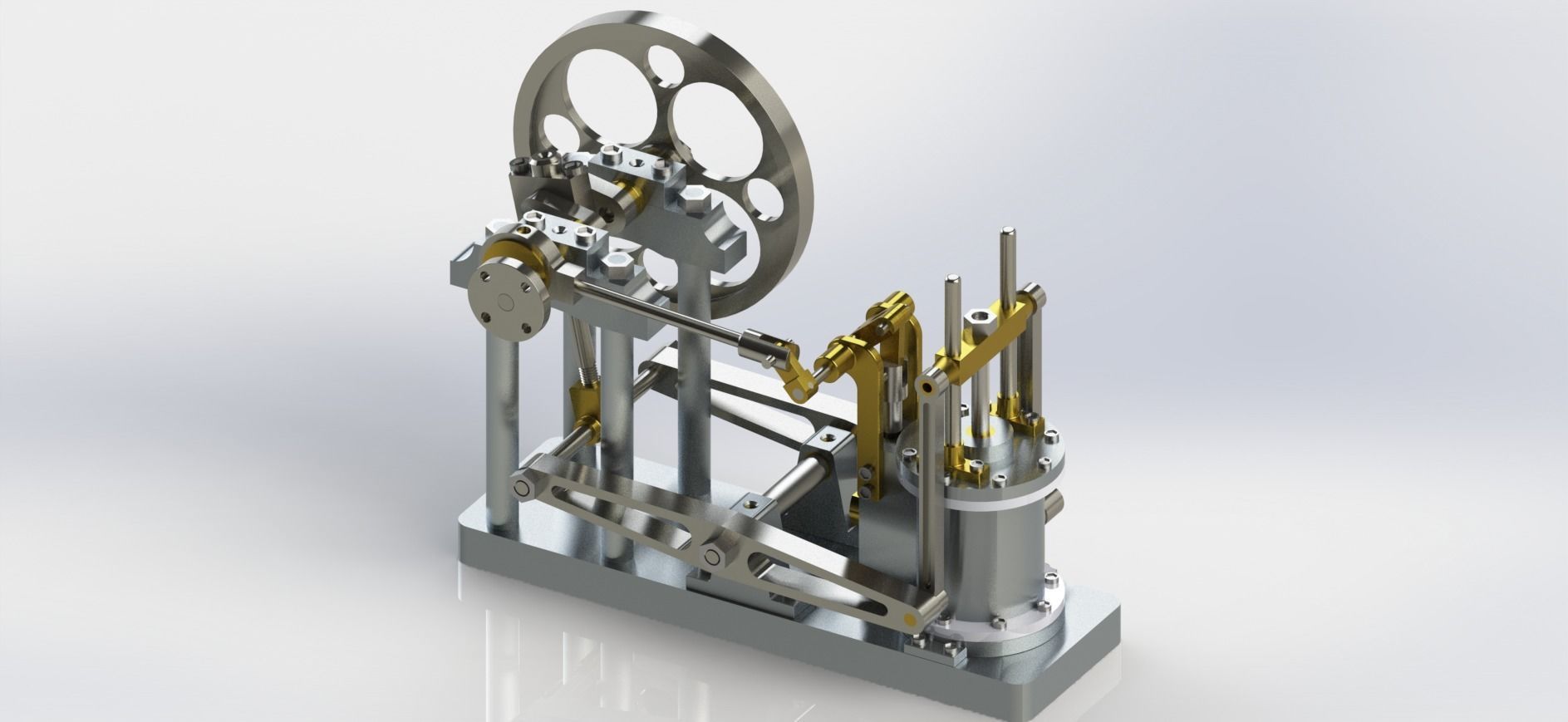

A SINGLE CYLINDER SIDE BEAM STEAM ENGINE 3D model

A SINGLE CYLINDER SIDE BEAM STEAM ENGINESOLIDWORK PART MODELLING AND ASSEMBLYSOLIDWORK MOTION STUDYhttps://www.cgtrader.com/lets-make-it-cad #SolidWorks #letsmakeitcad #steamengines

A single-cylinder side beam steam engine is a type of steam engine that features a single cylinder and utilizes a side-mounted beam mechanism. This type of engine design was commonly used in the early days of steam power and played a significant role in various industries during the Industrial Revolution. Here's an overview of its components and operation:

Components:

Cylinder: The main chamber where steam pressure is used to move a piston.Piston: A cylindrical object that fits snugly inside the cylinder and moves back and forth.Crankshaft: A rotating shaft connected to the piston that converts reciprocating motion into rotational motion.Connecting Rod: A rod that connects the piston to the crankshaft, transmitting the piston's motion to the crankshaft.Side Beam Mechanism: A beam attached to the connecting rod on one end and to the crankshaft on the other. It transforms the vertical motion of the piston into the rotational motion of the crankshaft.Working:

Steam Inlet: Steam is admitted into one end of the cylinder through a valve.Power Stroke: The steam enters the cylinder and pushes the piston away from the valve end. This is the power stroke. As the steam expands, it does work on the piston, converting its energy into motion.Exhaust: After the power stroke, a valve opens to allow the used steam to exit the cylinder.Piston Return: The beam mechanism, along with the connecting rod, moves the piston back to its original position. This is the exhaust stroke.Steam Switch: The process is repeated in a cyclical manner. The side beam mechanism ensures the conversion of the vertical piston motion into the rotational motion of the crankshaft.Advantages:

Historical Significance: Single-cylinder side beam steam engines played a crucial role in powering various industries during the early stages of the Industrial Revolution.Simplicity: This design is relatively simple and was well-suited for its time.Disadvantages:

Efficiency: The efficiency of this type of engine design can be limited due to the lack of optimization features found in more advanced designs.Maintenance: The simplicity of this design might lead to wear and tear, requiring frequent maintenance.While this type of engine design has largely been replaced by more advanced technologies, studying historical references and principles will provide insights into the foundations of steam power and engineering development.