1/17

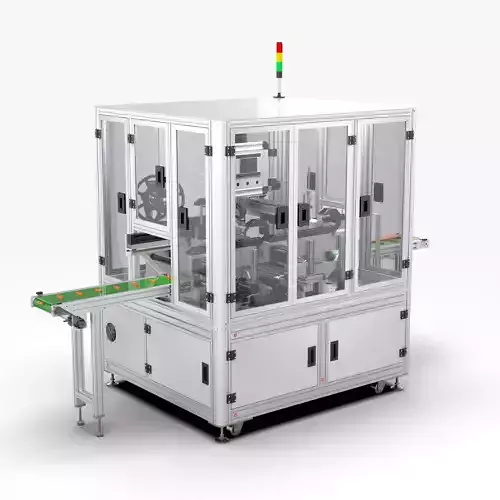

Automatic Polymer Battery Shaping and Labeling Machine

Introduction

This equipment is a special equipment for shaping, gluing and labeling of soft-packed polymer batteries. Manually put the battery on the pull wire and press the start button, and the equipment will start and enter the battery anti-discharge CCD test station. It flows into the equipment through the dust removal mechanism. If the battery is reversed, the device will give an alarm. Manually correct the battery and press the start button again. The battery will flow into the device through the dust removal mechanism. The loading and unloading manipulator picks up the battery and moves it to the shaping mechanism to carry out the CCD test after shaping the two sides of the battery, and then takes it to the positioning and labeling jig, and the motor drives the jig to move back to the labeling position. The label feeding feeder peels off the labels. The X, Y, Z, W four-axis manipulator picks up the label, and the CCD visually detects the position of the label. The information is transmitted to the system, and the system instructs the X, Y, Z, W four-axis manipulator to correct the deviation position. The manipulator moves to the labeling position. Stick the label on the battery. The shaping station returns to the designated position, the labeling mechanism releases the Z-direction cylinder to lift the battery up, the rollers on both sides of the surface wrap the two sides of the battery, and the folding robot grabs the battery and sends it to the folding station. First use a roller to roll the battery tab glue flat. After the CCD visual inspection is OK, then fold the tab tab, then fold the bottom two tabs, and finally fold the bottom edge. After completion, the manipulator transfers the battery to the unloading wire.

File Formats

- SolidWorks 2018 | Keyshot 10

- STEP (Standard for the Exchange of Product Data)

- IGES (Initial Graphics Exchange Specification)

- STL (Standard Tessellation Language )

- OBJ (Object Files)

Geometry

- Polygons: 3,514,085

- Vertice: 10,542,255

REVIEWS & COMMENTS

accuracy, and usability.