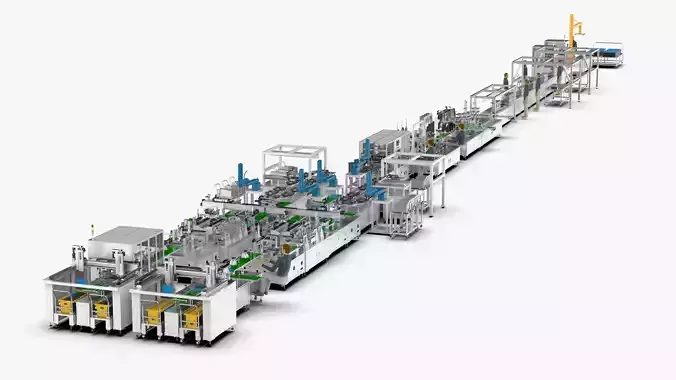

Automatic Soft Pack Battery Production Line

Introduction

The principle process of line body equipment includes.

- Cell loading, automatic cell loading (manual tearing film), double-sided tearing film of cell protection film, supply frequency of cell material frame >20min, use small AGV trolleys with plastic frame side materials to feed materials.

- Scan the battery cell code, read the bar code of the battery cell, record the MES system, read the incoming material parameters of the battery cell.

- Test the battery cell, measure the positive and negative poles Voltage internal resistance, side voltage and polarity judgment, record the MES system, and compare with the incoming battery parameters, automatically discharge the defective products, the system records the defective items and can correspond to the barcode.

- Tab cutting, according to processing requirements Cutting the positive and negative tabs.

- Tab shaping, mainly to prevent the deformation of the tabs of the battery cell.

- The discharge of the cell, the discharge of the cell is sent to the module assembly section, and the cells used for 1P/2P are transported to the module respectively.

- Stretcher feeding (bracket) 1P/2P stretcher feeding, stretcher material trolley loading, feeding frequency > 20min.

- Module assembly, the 1P sequence is: cell - support plate, the 2P sequence is: cell - support plate - cell.

- Partition assembly, cell module assembly.

- Cell into the shell, cell The module is assembled into the aluminum shell.

- Battery insulation test, single cell insulation test after welding, test the total positive and negative voltage internal resistance of the module; insulation test , group positive and negative voltage internal resistance; positive and negative poles and metal frame insulation withstand voltage test; input system, traceable, defective product discharge, qualified product molding and group coding,

- Shell pressing and assembly.

- Cell stacking, assembly and stacking of small module cells.

- Metal frame assembly and welding, module base and module Guard plate installation and laser welding, 4000W laser continuous welding, can appropriately increase the number of welding scars to improve reliability, penetration > 1.2mm (vertical peeling force > 300N)

- Bus bar copper bar connection.

- Module detection off-line , the whole line equipment includes all the processes of soft-pack VDA battery assembly and the equipment structure to realize various functions.

File Formats

- SolidWorks 2018 | Keyshot 10

- STEP (Standard for the Exchange of Product Data)

- IGES (Initial Graphics Exchange Specification)

- STL (Standard Tessellation Language )

- OBJ (Object Files)

- x_t (Parasolic Model Part File)

Geometry

- Polygons: 603,121,443

- Vertice: 810,242,109