1/6

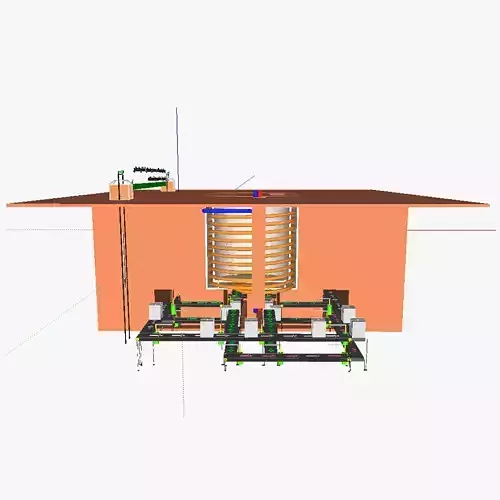

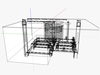

3D model of the modular kiln. Unlike traditional kilns, the modular kiln is buried in the ground so as to improve the thermal efficiency (the soil increases the insulation). It is also modular, allowing to melt several types of metal. Due to the smart use of the conveyor belts and the motorized pushers (which push the metal mould over the gaps between conveyor belts), no ladle furnaces are required. The conveyor belts are driven by motors aswell (green in model). These have not been wired, but if they are, the wires run through the pipe in which the wires of the smelting furnace allready run. Everything is automated as below the soil, the heat is confined and thus probably too high to allow people of working there. The casts are finished by people above the soil. Note that besides a kiln, another device that can be used to produce metal objects is a 3D printer. See the 'Purchasing_the_models' link at appropedia's AT_CAD_Team for additional information on the model

REVIEWS & COMMENTS

accuracy, and usability.