1/16

The model contains the most popular formats:

- 3DS MAX: *.max

- Blender: *.blend

- Rhinoceros: *.3dm

- SketchUp: *.skp

- Wavefront OBJ: *.obj *.mtl (Multi Format)

- FBX: *.fbx (Multi Format)

- STEP: *.step *.stp (NURBS)

- IGES: *.iges *.igs (NURBS)

- ACIS: *.sat (NURBS)

- 3DS MAX all ver.: *.3ds (Multi Format)

- Stereolithography: *.stl

- AutoCAD: *.dwg

- Each file was checked for opening and full content by the model.

- The 3D model was created on real base. It’s created accurately, in real units of measurement, qualitatively and maximally close to the original.

- Renders Are made in Luxion Keyshot

- “WE PROVIDE 3D MODEL CHEAP PRICE BUT WITH GOOD QUALITY”

- If you need any other formats we are more than happy to make them for you. Contact me for any question :)

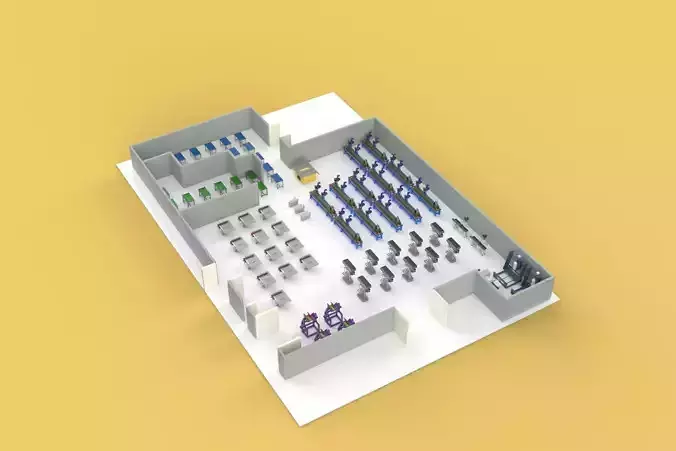

Sincerely Your, SURF3DMORE INFORMATION ABOUT 3D MODELS :From the focus on floor production plan, it sounds like this workshop dives deeper into the practical application of production line layout within a factory setting. Here's how it might differ from a general production line layout workshop:

Focus:

Implementation: This workshop likely emphasizes the hands-on aspects of creating a floor production plan for a specific production line.Factory Considerations: It delves into practical limitations and considerations specific to a factory environment, such as building dimensions, existing infrastructure, and safety regulations.Content:

Data Analysis: The workshop might include exercises on analyzing production data to identify bottlenecks and optimize workflow.Space Allocation: Participants might learn techniques for allocating space for equipment, storage, and worker movement within the factory floor plan.Production Flow Simulation: The workshop could involve using software or physical models to simulate material flow and identify potential issues in the planned layout.Documentation and Communication: Creating clear and detailed production floor plans, along with effective communication to stakeholders involved in implementation.By attending this workshop, participants gain the ability to:

Translate theory into practice: They'll learn to apply production line layout principles to create a real-world floor production plan.Address factory constraints: Develop skills to design layouts that work within the specific limitations of a particular factory environment.Improve communication and collaboration: Learn to effectively communicate production plans to various stakeholders involved in setting up the line.This workshop is ideal for production supervisors, engineers, or anyone involved in optimizing production efficiency within a factory setting.

REVIEWS & COMMENTS

accuracy, and usability.