1/33

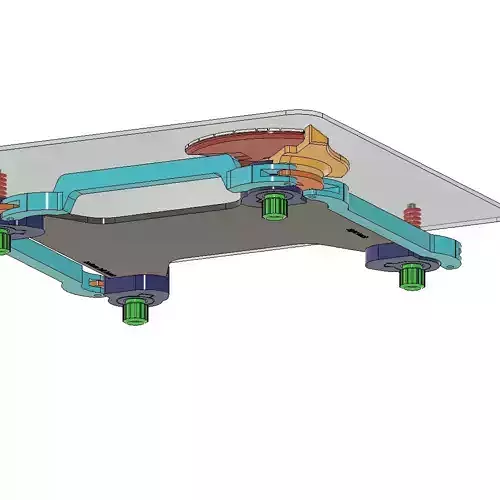

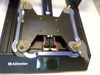

3D MODEL DESCRIPTION3d printed model for printers build plate ,allow the build plate to move up or down as on unit, (from 0 = 0.1 = 0.15 = 0.2 = 0.3 = 0.4 = 0.5 = to 0.6 ) after assembly oll the parts ,adjust the build plate to the normel size you allways do (i use 0.2 mm paper) before adjusting make sure the pointer points to the same number (in my case -0.2) after that when you move the pointer to another number ,the gap in oll the 4 nuts will change toghter. so if you want fast print of 0.3 and move to 0.1 for exemple, oll you have to do is move the pointer to 0.1.Recommended after the first prints to adjust again so oll the part sits in place.made in the size of alfawise u50 which have 180x180 mm builde plate but can change to any printer just need tyo change the size of the rodes (i add picture with the size of my build plate) . If you have a question or need help please contact me

i print oll the bodys,the rods,the pointer and number plate , on 0.3 layer hight,50 speed,infill 30% with super pla, for oll the top nuts (4) and the handle(4) and the number(just the small plate) i use nornal- 0.15 ,print speed 30 infill-60%,support (if needed) over hang angle 78 deg,

3D file format: STL

REVIEWS & COMMENTS

accuracy, and usability.