3D Features

The model includes animations (movement or actions) that can be played in supported software or engines.

The model has a skeleton or bone structure, making it ready for posing or animation.

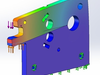

PBR

Uses Physically Based Rendering materials, which give the model realistic lighting and surface properties.

Textures

The model includes image files (textures) that add color, patterns, or detail to its surfaces.

Materials

The model has material settings that define how surfaces look (color, shine, transparency, etc.).

UV Mapping

The model's surfaces are mapped to a 2D image, allowing textures to display correctly.

Plugins Used

Some external plugins were used to create the model. These may be required for full functionality.

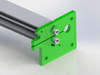

3D printing

Indicates whether the designer marked this model as suitable for 3D printing.

Model is not 3D printable

The designer indicates this model is intended for digital use only (rendering, animation, or AR/VR) and not for 3D printing.

Geometry

Polygon mesh

A model built from polygons (triangles or quads) connected in a mesh.

Unwrapped UVs

Unknown

Publish date

2016-04-15

Model ID

#313163