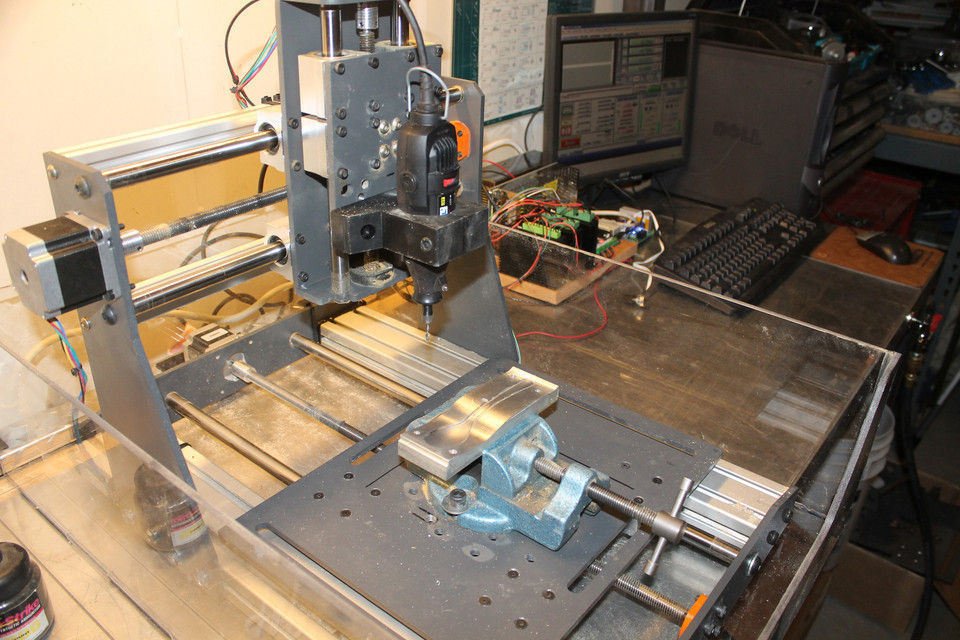

CNC router benchtop mill Free 3D model

I designed and built this router from laser cut 1/4" steel plate, electronic components from China, bearing blocks from China and 1/2"-13 rod for leadscrews. It works great at 20 ipm max rapid and has good rigidity for milling aluminum (I cut my molds with it). Total project cost with upgraded 400 watt spindle was about $600. The model shows a harbor freight 2 hp router. It's an awesome spindle and I have every size from .125"-.5", but is just too big, bulky, and loud (even with the dimmer switch). I first used a dremel and that tool is good for cutting anything made of foam and softer. I would stall the motor trying to make light cuts in wood with a 1/8" endmill! I do not recommend making a Dremel cnc router. I 3d printed some parts to hold the nuts and bearings, hoping to get it up and running, but the abs parts are holding up quite strong, I'm not sure I'll need to machine permanent parts.