1/7

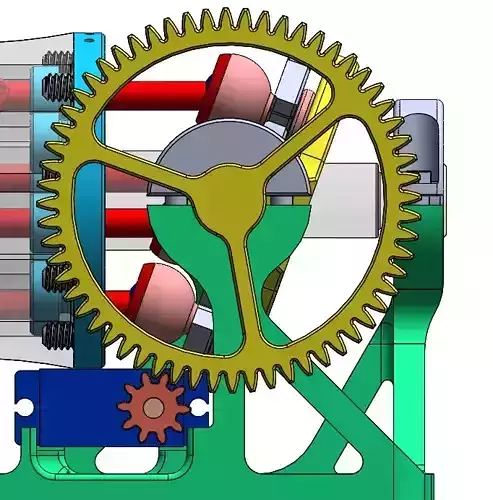

An involute 1:6 gear, small part (10 teeth) designed to attach an electric servo with perfect spline teeth and big part (60 teeth) is designed to attach another part with a screw.The involute gear profile is the most commonly used system for gearing today, with cycloid gearing still used for some specialties such as clocks. In an involute gear, the profiles of the teeth are involutes of a circle. The involute of a circle is the spiraling curve traced by the end of an imaginary taut string unwinding itself from that stationary circle called the base circle, or (equivalently) a triangle wave projected on the circumference of a circle.In involute gear design, contact between a pair of gear teeth occurs at a single instantaneous point (see figure at right) where two involutes of the same spiral hand meet. Contact on the other side of the teeth is where both involutes are of the other spiral hand. Rotation of the gears causes the location of this contact point to move across the respective tooth surfaces. The tangent at any point of the curve is perpendicular to the generating line irrespective of the mounting distance of the gears. Thus the line of the force follows the generating line, and is thus tangent to the two base circles, and is known as the line of action (also called pressure line or line of contact). When this is true, the gears obey the fundamental law of gearing.

a well working printed gear, I work with it a lot and its perfect.Struggling to print a good working gear? try this one and leave a comment below.

REVIEWS & COMMENTS

accuracy, and usability.