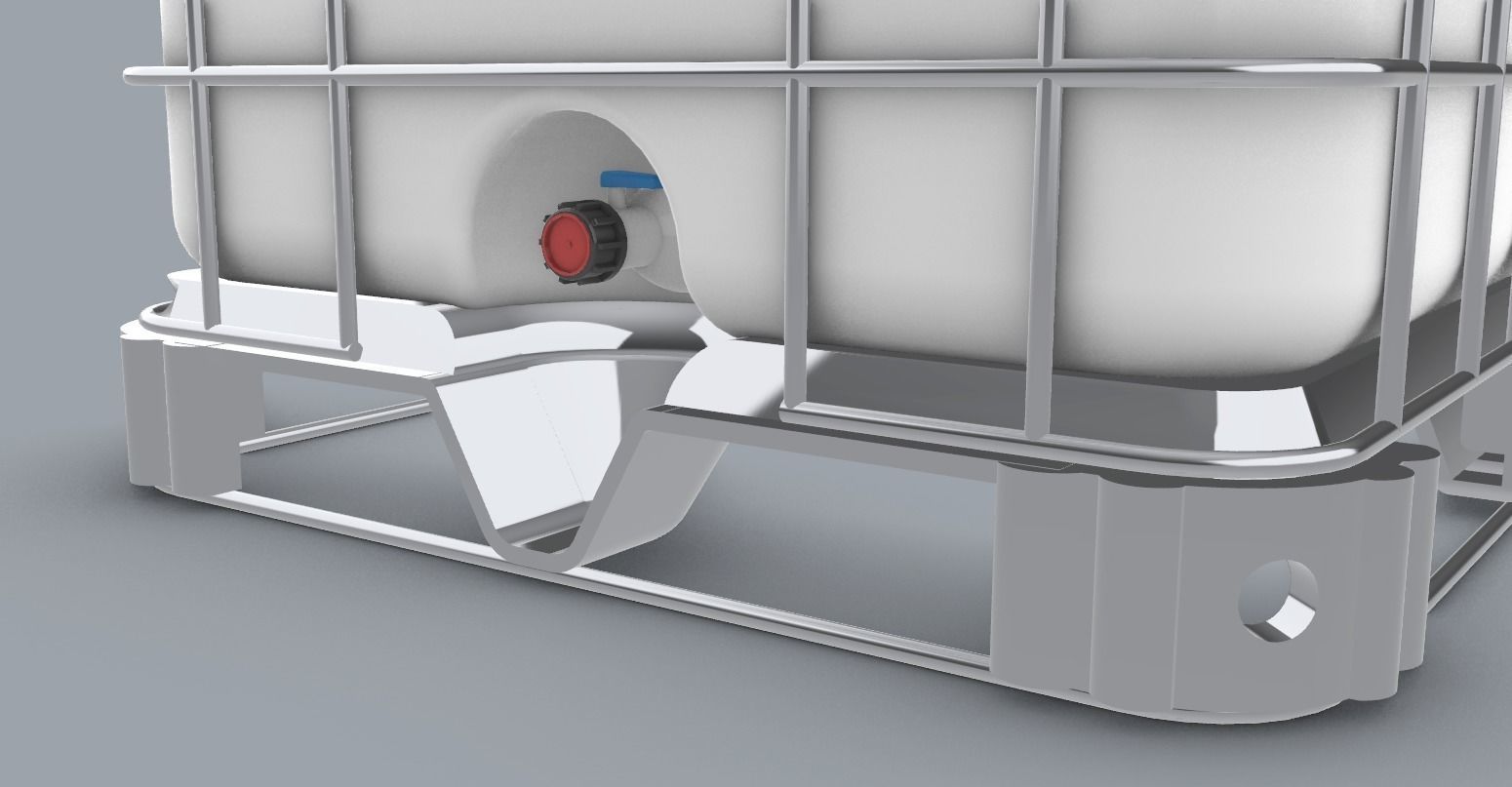

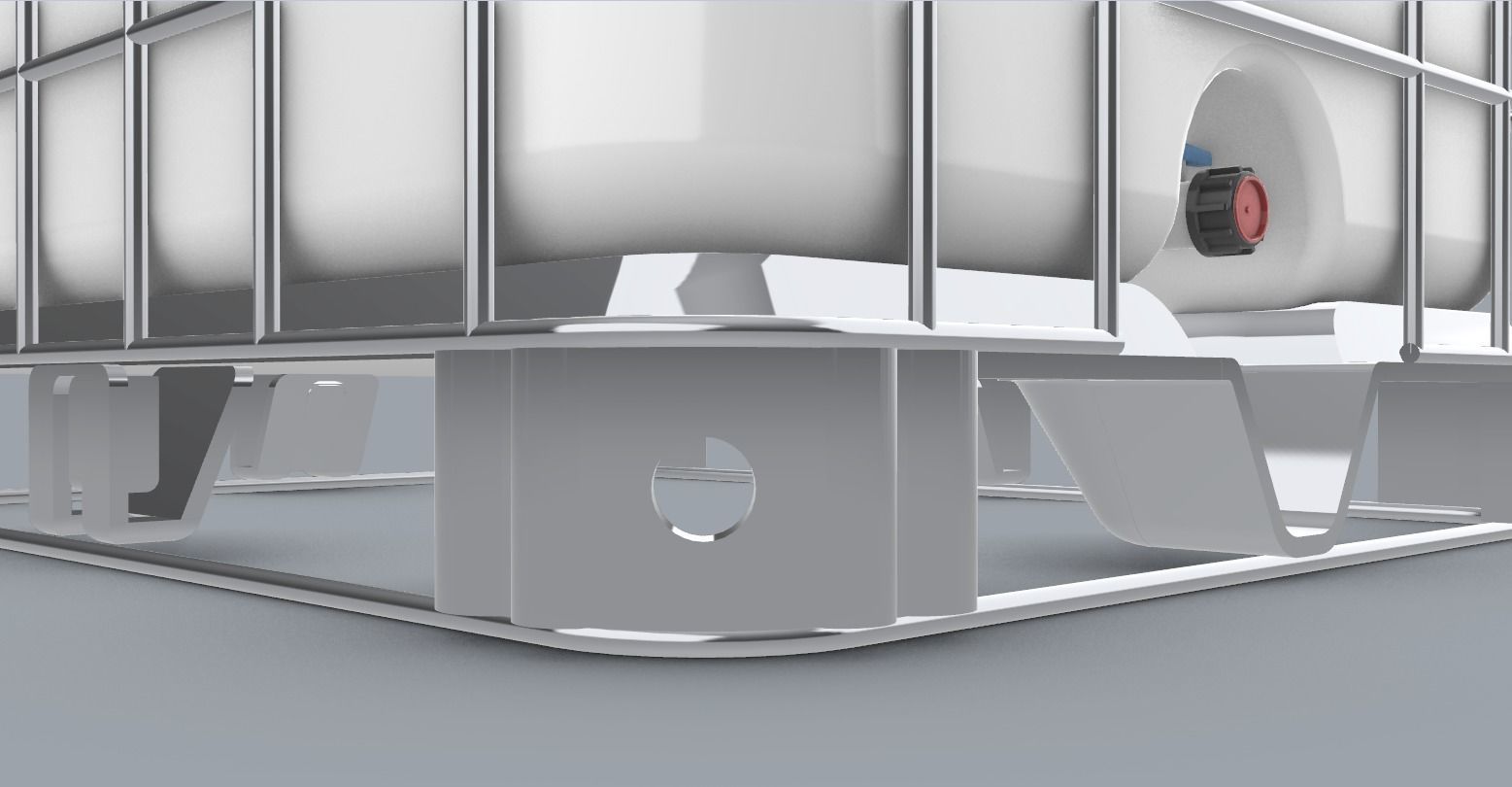

IBC Container PM 3D print model

3D Model of IBC Container, made for 3D Model of Vos Fabulous

Model is ready to be used in 3D Printing, Design, CNC..

Notes:

All models are preprinted in order to get highest quality possible.

Model is simplified for printing.

Dimensions

Length: 16.84mm

Width: 20.21mm

Height: 18.15mm

Includes OBJ and STL file.

http://hovla.net

About

Intermediate bulk containers (also known as IBC tank, IBC tote, IBC, or pallet tank) are industrial-grade containers engineered for the mass handling, transport, and storage of liquids, semi-solids, pastes, or solids.[1] The two main categories of IBC tanks are flexible IBCs and rigid IBCs.[2] Many IBCs are reused or repurposed.[3] Rigid IBCs are stackable, reusable, versatile containers made from metal, plastic, or a composite of the two, designed for forklift and pallet jack maneuverability. They can hold up to 3 cubic metres (793 US gal) and are used for the transport of both hazardous and non-hazardous materials. Flexible IBCs, typically made from heavy polymers, are designed for storing or transporting dry, flowable products like sand or fertilizer. The cubic shape of IBCs allows for efficient transport and storage, and they can be custom-made based on specific customer requirements. IBCs are often used for shipping, handling, and storage of bulk chemicals, food ingredients, petrochemical products, paints, pharmaceutical compounds, and more. These containers can be purchased new, rebottled, or washed, and can be tracked using bar code and RFID tracking systems. When used for flammable or combustible liquids, IBCs should be clearly labeled and stored properly for safety reasons.Rigid intermediate bulk containers are stackable, reusable, versatile containers with an integrated pallet base mount that provides forklift and/or pallet jack maneuverability. These containers can be made from metal, plastic, or a composite construction of the two materials. Rigid IBC design types are manufactured across a volume range that is in between that of standard shipping drums and intermodal tank containers, hence the title intermediate“ bulk container. IBC totes are authorized per Title 49 CFR codes[4] to be fabricated of a volume up to 3 cubic metres (793 US gal) while maintaining theIBC" name and their federal shipping and handling permits. IBC tank capacities generally used are often 1,040 and 1,250 litres (275 and 330 US gal).[5] Intermediate bulk containers are standardized shipping containers often UN/DOT certified for the transport handling of hazardous and non-hazardous, packing group II and packing group III commodities. Many IBC totes are manufactured according to federal and NSF/ANSI regulations and mandates, and are often IMDG approved as well for domestic and maritime transport. Metal alloy IBC tanks are also manufactured according to NFPA and UL142 certification standards for extensive storage of materials labeled as flammable and/or combustible.[6] Intermediate bulk containers can be manufactured from various materials based on the requirements of the application or service the IBC will be used for.