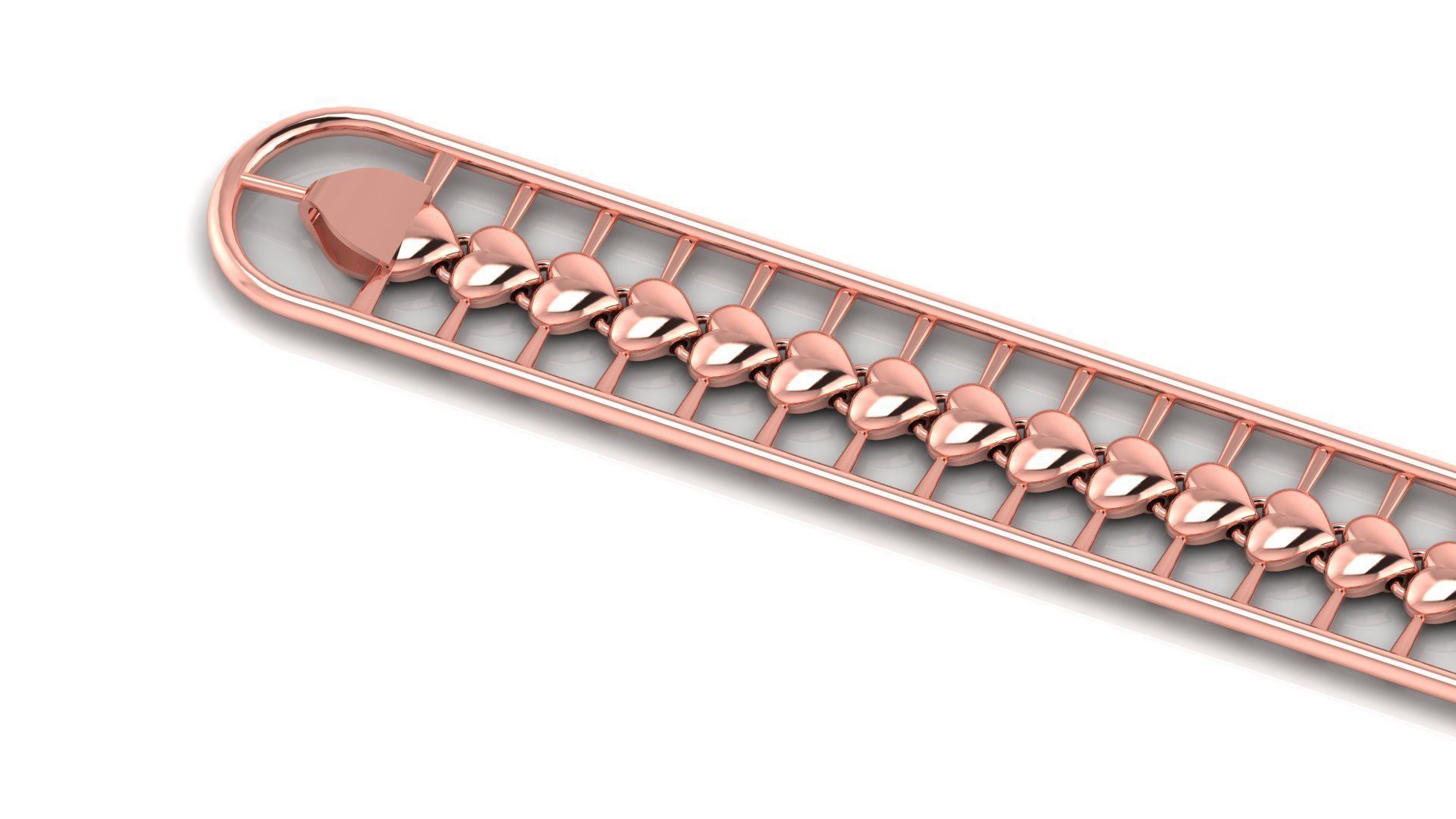

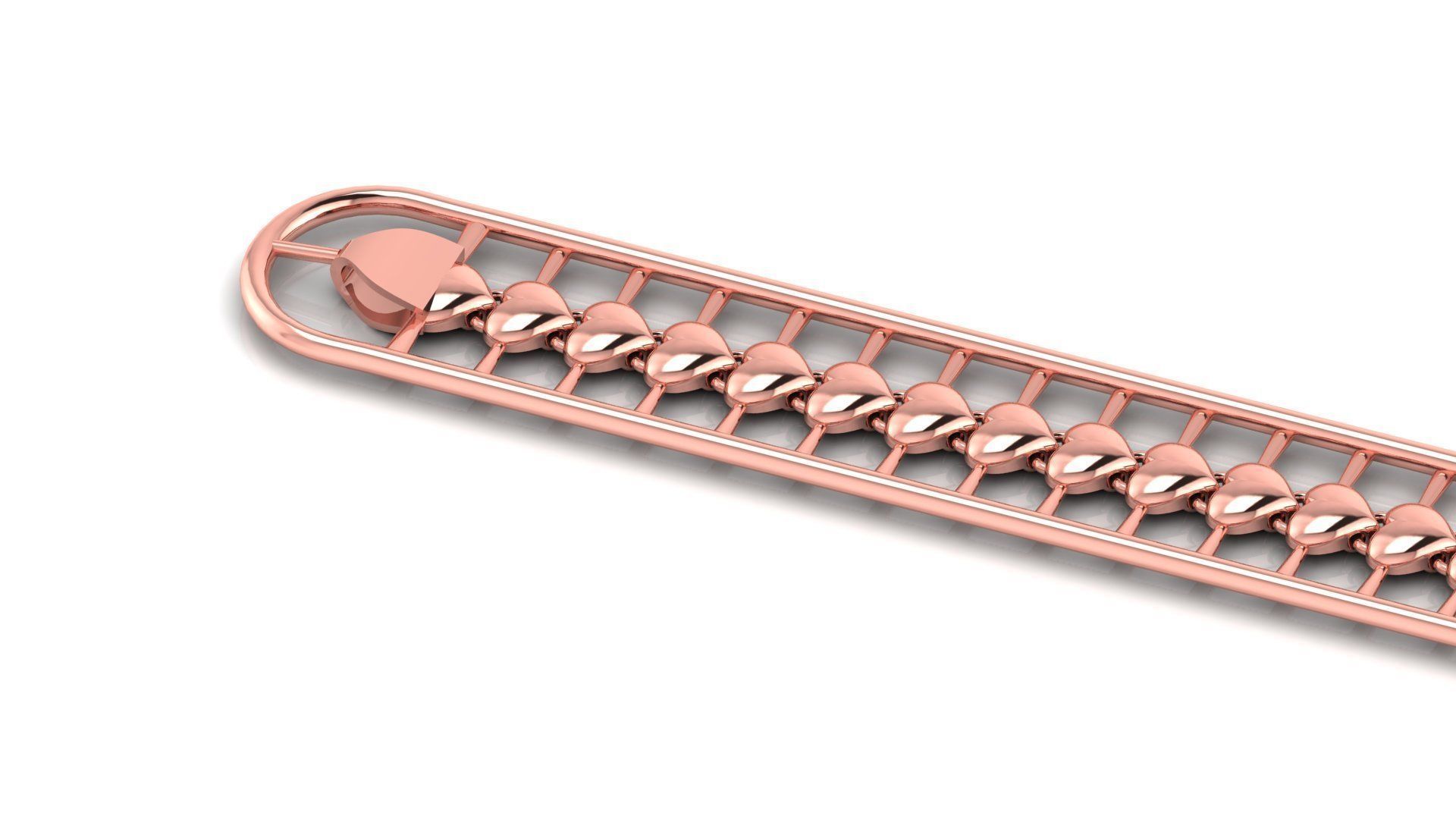

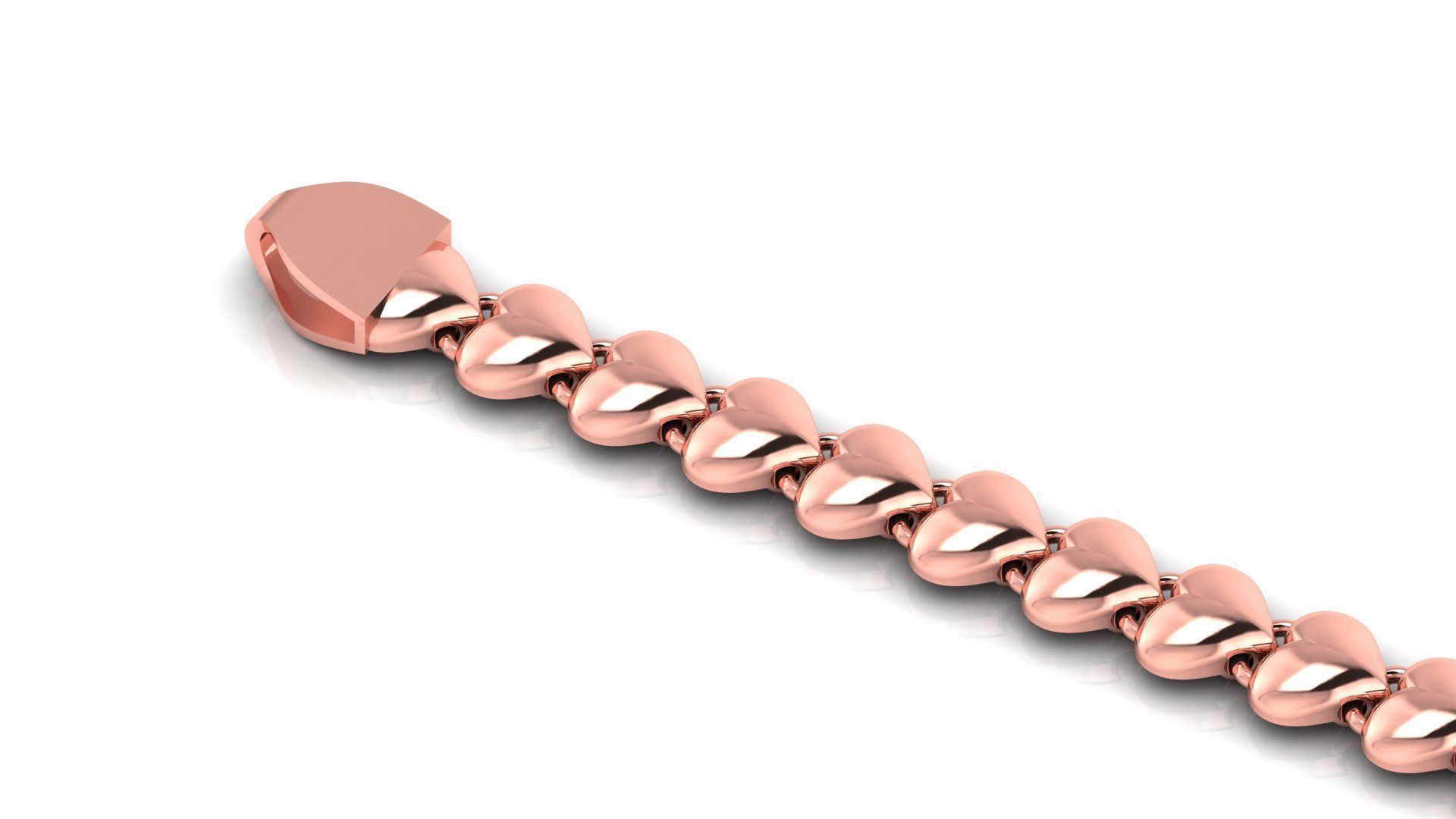

ladies 3d chain or necklace or bracelet 3d model 3D print model

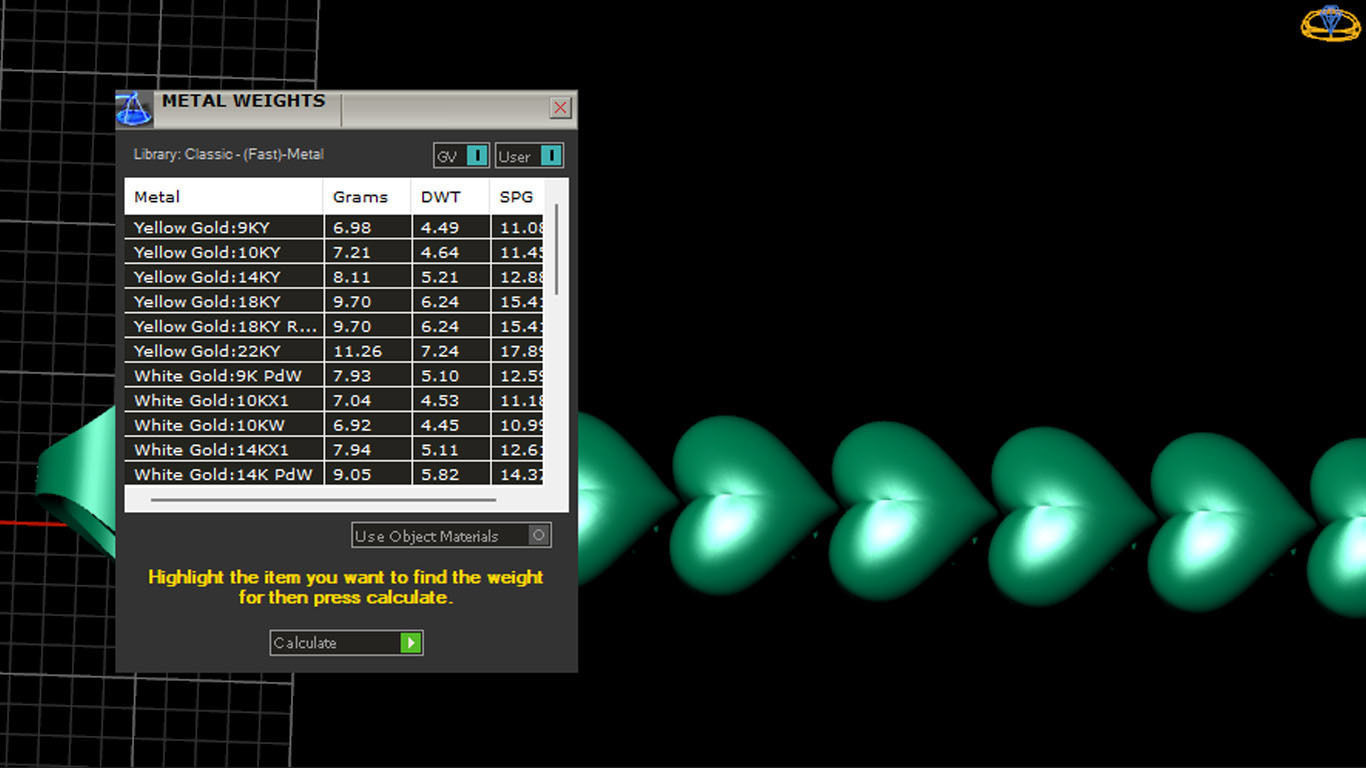

3d model bracelet weight AND SIZE ARE SHOWN IN IMAGE All STL files

NOTE: FULLY UNIFIED AND MESH REPAIRED AND YOU CAN GIVE IT TO ANY CAM MACHINE WITHOUT ANY ERROR IF YOU NEED A CUSTOM DESIGN PLEASE CONTACT USCreating a high-quality 3D model of a bracelet involves meticulous attention to detail and craftsmanship. Here's how we do it:

Conceptualization: We begin by conceptualizing the design, drawing inspiration from various sources such as nature, architecture, or cultural motifs. This initial phase sets the foundation for the overall aesthetic and style of the bracelet.

Digital Sculpting: Using advanced 3D modeling software, we sculpt the bracelet digitally, refining its shape, proportions, and surface details. This process allows us to achieve a level of precision and intricacy that would be difficult to achieve through traditional methods.

Detailing: We pay close attention to every detail, adding intricate patterns, textures, and embellishments to enhance the visual appeal of the bracelet. Whether it's delicate filigree work, geometric patterns, or sculptural elements, each detail is meticulously crafted to elevate the design.

Optimization: Once the design is complete, we optimize the model for 3D printing, ensuring that it is structurally sound and printable with high fidelity. This may involve refining geometry, adding support structures, or adjusting thickness to achieve optimal printability.

Material Selection: We carefully select the appropriate material for the bracelet, taking into consideration factors such as durability, aesthetics, and compatibility with the printing process. Whether it's precious metals, durable plastics, or innovative composite materials, we choose materials that meet our standards for quality and performance.

Quality Assurance: Before proceeding to 3D printing, we conduct thorough quality assurance checks to ensure that the model meets our standards for accuracy and integrity. This may involve reviewing the model from multiple angles, performing test prints, or making any necessary adjustments to optimize the final result.

Printing and Finishing: Once the model is ready, we proceed to 3D printing using state-of-the-art printers and premium materials. After printing, the bracelet undergoes meticulous post-processing and finishing techniques, such as polishing, painting, or plating, to enhance its appearance and durability.

Final Inspection: Before the bracelet is ready for presentation or sale, it undergoes a final inspection to ensure that it meets our strict quality standards. This includes checking for any imperfections, inconsistencies, or defects that may have occurred during the printing or finishing process.

By adhering to these rigorous standards and processes, we ensure that each 3D-printed bracelet we create is a masterpiece of craftsmanship and quality, worthy of adorning the wrists of discerning wearers.