1/4

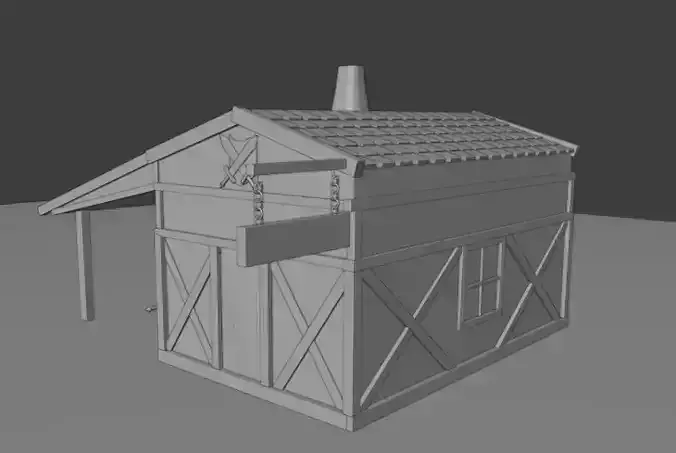

Forge or smithy - a workshop in which metal is hand-worked, usually by forging.

It necessarily included a hearth (forge) and an anvil. In the forge, you can perform almost all primary operations when working with metal: melting metal, pouring it into a mold, as well as subsequent ones, including: free forging, forging welding, copper brazing, heat treatment of products, hardening, stamping, drawing, bending, torsion, embossing and so on.

The person who carries out all these operations and works in the forge is a blacksmith.

In the recent past, the smithy was the main place for the manufacture of weapons and tools. Blacksmithing and blacksmithing have a long history. Man has long known the simplest blacksmith tools for forging: a hammer, tongs and anvil, and the simplest heating equipment - a forge, as well as a device for forcing air - bellows. The first mechanization of forging processes dates back to the 16th century, when mechanical lever, water-driven hammers, driven by the energy of a water stream, began to be used. In the absence of hydropower, piling (falling) hammers were used.

Due to the low productivity of labor and scientific and technological progress, the forge lost its significance; manual production was replaced by factory line production. The workshop was replaced by forging shops with mechanical and hydraulic hammers, rolling mills and so on. In a modern smithy, as a rule, they are engaged in hand-made artistic forging and piece goods are made [1]. The revival of artistic forging in modern Russia is associated with an increase in demand for the Baroque style, which often uses forged elements.

REVIEWS & COMMENTS

accuracy, and usability.