1/21

Video can be found here:https://youtu.be/d8us3OWgS1A

These files are the Fusion 360 source files of this project.

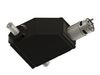

This servo/gearbox is the new and improved version of my original gearbox design (https://www.thingiverse.com/thing:3292860). The original one had a gear ratio of 30:1 and the speed of the output shaft was about 715 RPM which made it difficult to tune in the right PID parameters. This new version has a gear ratio of about 162:1 which lowers the speed and increases the torque of the output shaft.

I choose to go for double helical gears on this one because they produce a lot less noice than regular spur gears and the forces on the teeth are transferred more gradually. The gears rotate around a 6mm stainless steel shaft which is lubricated with bearing grease. Ideally all the gears should have some bearings, this is being considered for the next moment. Unlike my previous design I used 2 20mm bearings to support the output shaft.

The servo uses a 775 36V 9000rpm brushed DC-motor which is driven by my Universal Morion Controller (UMC)(https://www.thingiverse.com/thing:4245315). The stall torque theoretically is about 297kg/cm, I was able to test the servo to a torque of about 132kg/cm. During testing none of the gears broke, they were all printed in PLA. The weak link in this design however where the mounting tabs and the bevel gears used in the first stage on the motor shaft. These 2 gears tend to slip under high loads ,like when i tried to pull the car forwards with it's handbrake on, but this didn't occur when i performed the test where it pulled 132kg/cm of torque so it should be fine to at least this torque rating.

Video can be found here:https://youtu.be/d8us3OWgS1A

More info can be found here:https://hackaday.io/project/173854-3d-printed-high-torque-servogearbox-version-2

Components used:

11 × 3D printed componentsCan be found on Thingiverse

1 × 775 brushed motorlink:https://www.banggood.com/775-Gear-Motor-DC-12V-36V-3500-9000RPM-Motor-Large-Torque-High-power-Motor-p-1091058.html?p=E01411629100201406T1&custlinkid=255143

1 × M3 Bolt and nut 30mmdimension: 30mm lenght, Used to secure the small possition feedback gear to the 20mm shaft

1 × Universal Motion ControllerAnother project of mine used to control and drive the servo:https://hackaday.io/project/170604-umc-universal-motion-controller

1 × heat shrinkshttps://www.banggood.com/328pcs-Heat-Shrink-Tubing-Insulation-Electrical-Shrinkable-Tube-Sleeve-Cable-21-p-1362019.html?p=E01411629100201406T1&custlinkid=669227

2 × 6mm stainless steel shaftslink:https://www.banggood.com/681012mm-Diameter-550mm-Length-Linear-Rail-Shaft-Rod-for-3D-Printer-p-1533105.html?p=E01411629100201406T1&custlinkid=1206718

7 × screws 30mm lenghtdimension: 4.5mm diameter, 30mm lenght, Used to mount the lid

2 × 20mm inner diameter 6004 bearings (204212mm)link:https://www.banggood.com/Deep-Groove-Ball-Bearings-6000-60052RS-High-Speed-Bearing-Steel-p-942862.html?p=E01411629100201406T1&custlinkid=1206865

2 × Screws 15mm lenghtdimension: 4.5mm diameter, 15mm lenght, Used to mount the motor

1 × 10K potentiometerlink:https://www.banggood.com/5pcs-200V-0_2W-10K-Ohm-Potentiometer-Single-Linear-p-961348.html?p=E01411629100201406T1&custlinkid=1206871

2 × M5 bolt and nut 40mmdimension: 40mm lenght, Used to secure the big gear and servo arm in place

Tools used:

SMD rework station:https://www.banggood.com/YAOGONG-8878D-2-In-1-SMD-Rework-Soldering-Station-Hot-Air-Gun-Welding-Solder-Iron-Repair-Tool-p-1348341.html?p=E01411629100201406T1&custlinkid=1206705

Infrared digital thermometer:https://www.banggood.com/AKKU-Infrared-Digital-Thermometer-Handheld-Infrared-Thermometer-Industrial-High-Temperature-Thermometer-Laser-Temperature-Measurement-Gray-p-1595938.html?p=E01411629100201406T1&custlinkid=1179895

PLA filament:https://www.banggood.com/Creality-3D-White-or-Black-or-Yellow-or-Blue-or-Red-1KG-1_75mm-PLA-Filament-For-3D-Printer-p-1290153.html?p=E01411629100201406T1&custlinkid=926158

Recommended 3D-printer:https://www.banggood.com/Creality-3D-Ender-3-Pro-V-slot-Prusa-I3-DIY-3D-Printer-Kit-p-1346320.html?p=E01411629100201406T1&custlinkid=677427

REVIEWS & COMMENTS

accuracy, and usability.