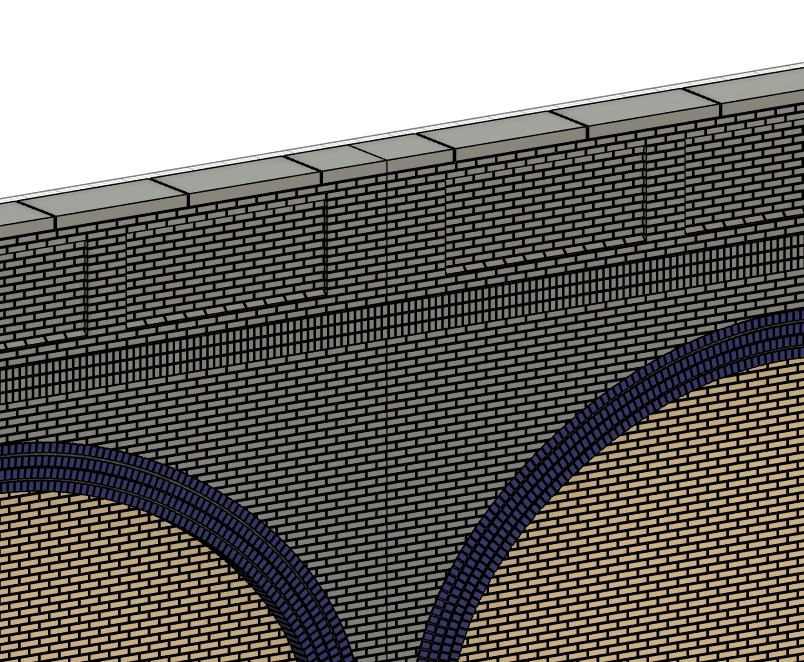

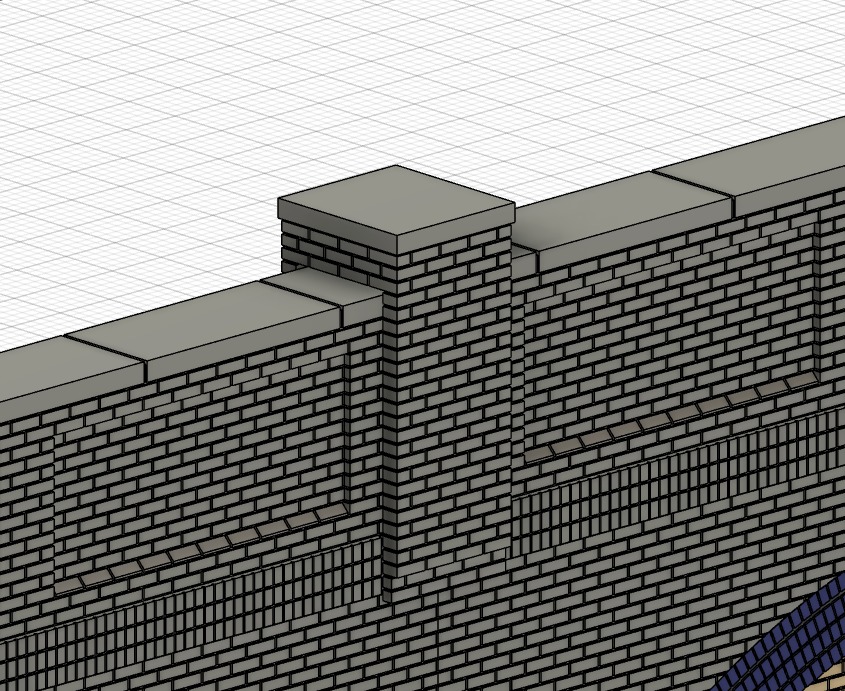

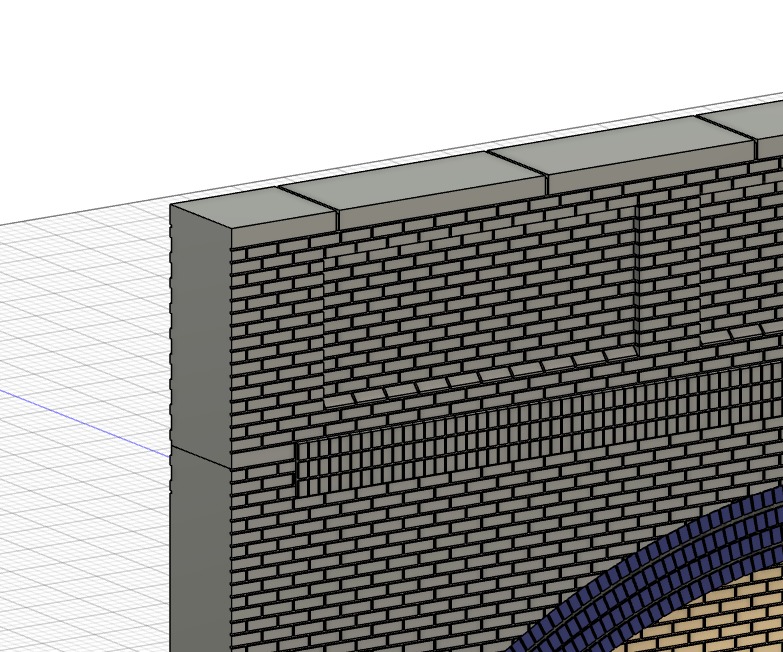

Model Railway Retaining Walls with Arches Modular Design 3D print model

This is a big project I have been planning on doing for a while and will lead to other associated items that can be fitted in the arches.

Also you might be interested in the following add-ons.https://www.cgtrader.com/3d-print-models/hobby-diy/other/model-railway-brick-arch-underpass-add-on-component

These items have been designed at 1/76 scale but can be printed at other scales.Primarily these items have been designed to be printed on a FDM printer but can also be printed on a Resin Printer.designed at OO gauge, 1/76.2 scale.for HO gauge print at 87%, 1/87 Scale,for O gauge UK at 175%, 1/43.5 Scale,for O gauge International print at 158%, 1/48 Scale,for N gauge print at 51.49%, 1/148 Scale, (Caution: I have not printed this model in N gauge so can’t guarantee its printability)

This is the base design that just has brick infill for the arches, this design can be used as a back scene or the front and back of a raised section of track.

Each Section is designed at 240mm wide with two arches, I will also add individual short arches that are 120mm wide that can be also printed on a resin printer or an FDM printer with a smaller print area. The longer 240mm sections will probably need to be printed on an FDM printer. For FDM printing I would print upside down or flat, this is because the design has no overhangs when printed upside down. With resin, it's up to you how you want to print, but please look at my example. When printing with a resin printer I recommend printing hollowed with a 2mm wall thickness and also have an infill support structure, this will reduce the amount of resin used.

If you’re planning of using with raised section of track I have designed two height versions of 100mm and 120mm, therefor you can have a raised section of track 80mm to 100mm in height. Files ending in 100 are the 100m high version and 120 the 120mm high version. The arches are 9mm deep, this is to allow space for Industrial and shop detail with later designs.

Each arch will take a while to print due to detail and size, but they will work out cheaper to produce than printed or injection models on the market. I have added some brick sections that can help disguise joins and there will also be brick columns to go on each end if required.

The double arch 100m high when printed on a FDM printer uses approx. 100g of filament and takes 16 hours to print vertically with a layer height of 0.08mm. If printed flat on bed it takes just under 9 hours to print. Personally, I think the detail comes out better if printed vertically. These figures are based on that the Bambu Labs slicer reported for my A1 printer, other printers will use different amounts of filament and print at different speeds.

The plan is to add some alternative solutions for what is portrayed in the arches, I want to develop industrial and shop fronts. I also plan to have some 50mm and 100mm deep arches so you can have detail under the tracks or roads for raised sections.

This is a set of designs that will evolve over the autumn of 2024, so if certain items are not available yet they may be added in the near future. Please also contact me with any ideas you have that you might want including, but no guarantee's they will be added.

Additional Info

Please checkout my Website, https://sites.google.com/view/pete3dprintinghelp/home

My website has lots of useful info.