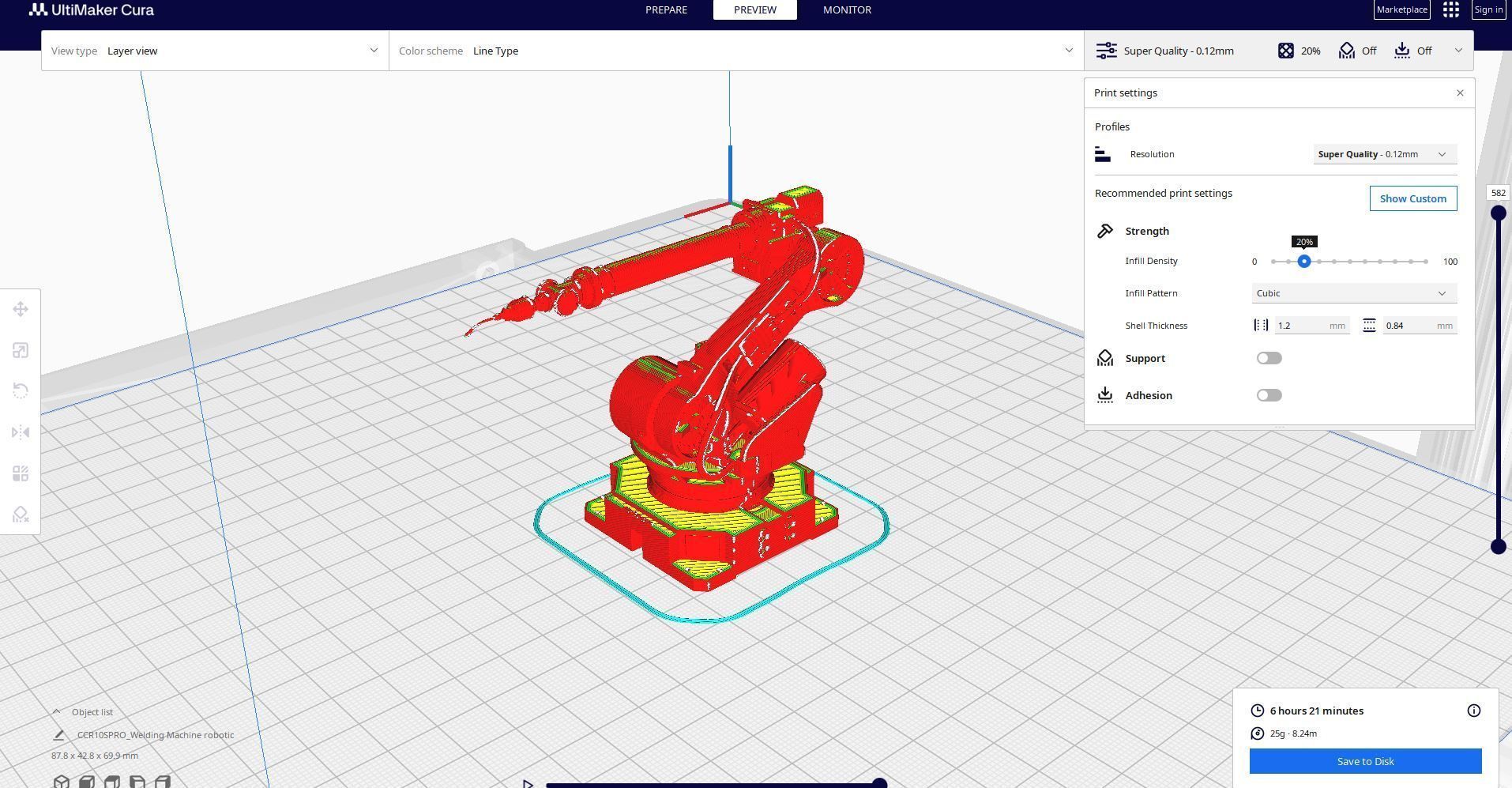

welding machine robotic 3D print model

A 3D-printed welding machine robotic system represents a significant advancement in automation and precision welding technology, utilizing additive manufacturing to produce custom components and structures. This approach allows for the creation of complex, intricate parts such as robotic arms, welding nozzles, and support frames, all optimized for specific welding tasks and environments. By leveraging 3D printing, manufacturers can design and produce components with enhanced functionality, improved ergonomics, and reduced weight, leading to more efficient and precise welding operations. The use of high-strength, heat-resistant materials like advanced polymers or metal alloys ensures durability and performance under demanding conditions. This technology not only streamlines production and reduces costs but also enables highly customizable and adaptable solutions for a wide range of industrial welding applications, from automotive assembly to aerospace manufacturing.