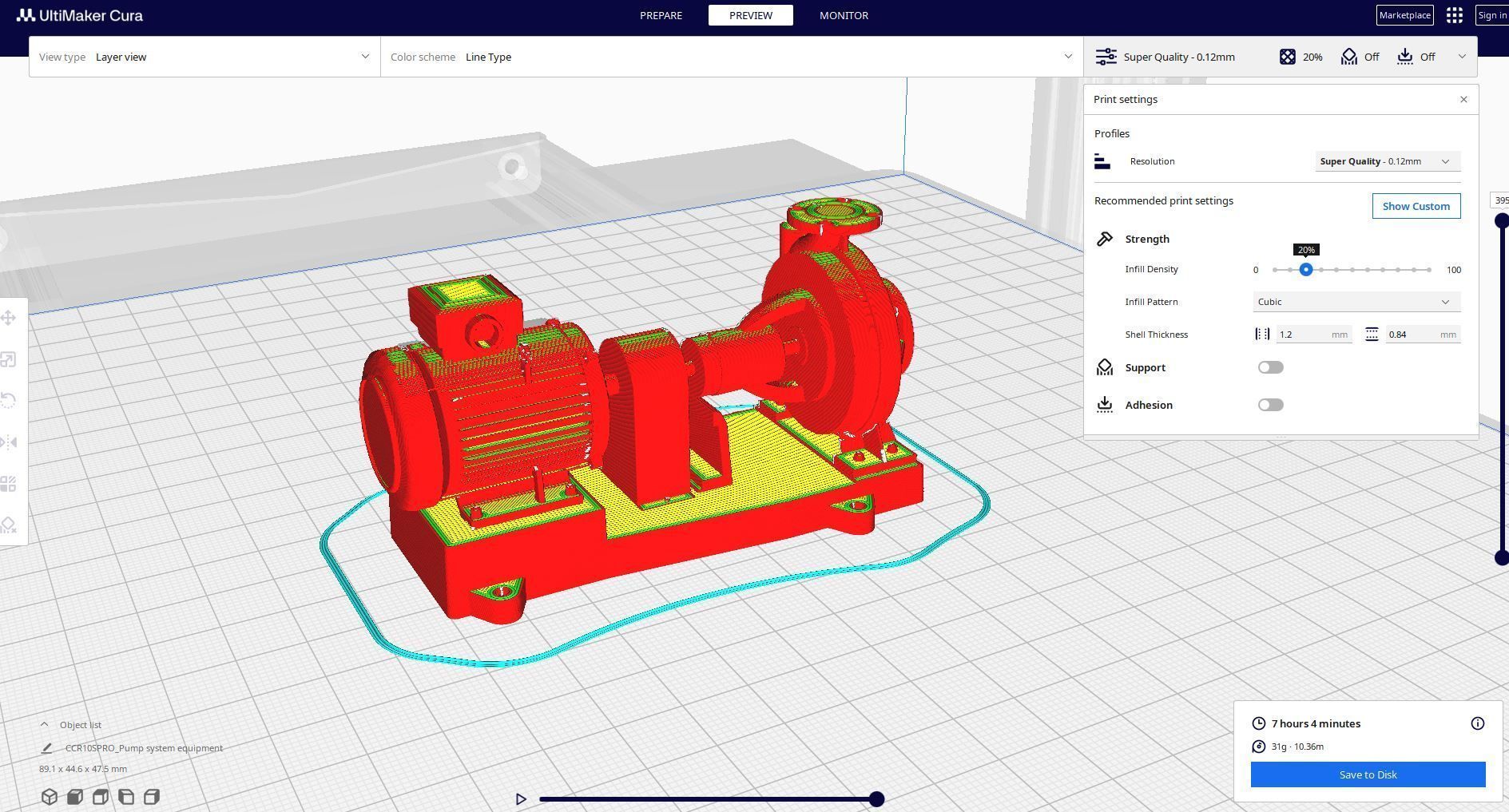

pump system equipment 3D print model

A 3D-printed pump system equipment consists of various components such as impellers, housings, and seals, all produced through additive manufacturing technology. This approach allows for highly customizable designs that enhance the performance and efficiency of the overall pump system. By leveraging 3D printing, manufacturers can create complex geometries that optimize fluid dynamics, reduce energy consumption, and improve flow rates. The use of durable, corrosion-resistant materials, including advanced polymers and metal alloys, ensures that the equipment can withstand harsh operating conditions in industries such as water treatment, chemical processing, and oil and gas. 3D-printed pump system equipment offers a lightweight, cost-effective solution with quicker production times, reduced material waste, and enhanced precision.