MKIII 3D Printed Vibrating Bowl Feeder - Full Release 3D print model

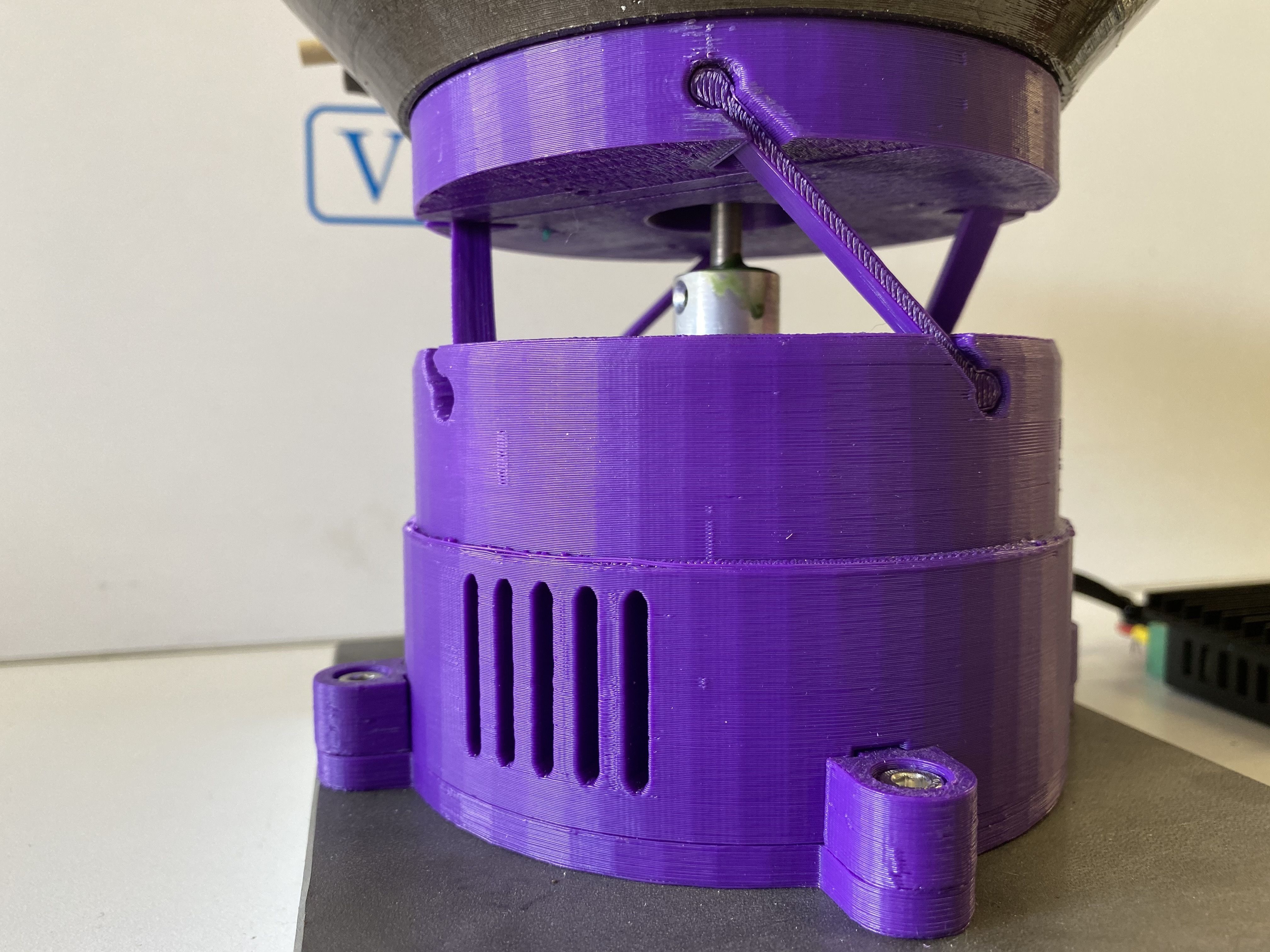

This is the current full release of our vibrating bowl feeder. Dimensionally this is very similar to our MKII feeder, but performance wise it is miles ahead. If you are thinking about using one of these printed feeders for a practical application, then this is the one for you!

Instead of using a DC motor, this one uses a Nema17 stepper motor for excitation. This makes tuning the amplitude and frequency of the bowl a much simpler and more reliable process.

This bundle includes all of the STL files, as well as the original SolidWorks files and STEP files in case you want to reverse engineer anything. You get all of the final release files, as well as a few developmental and alternate bowl styles. This was printed in ABS material for it's favorable wear characteristics and springiness, but any similar polymer should work well.

Assembly is reasonably straightforward, with most parts simply cliping together. The major parts are held in place with M3 screws.You can see a short montage of the printed pieces and how they fit together here: https://youtu.be/JiTt6AGZsMs

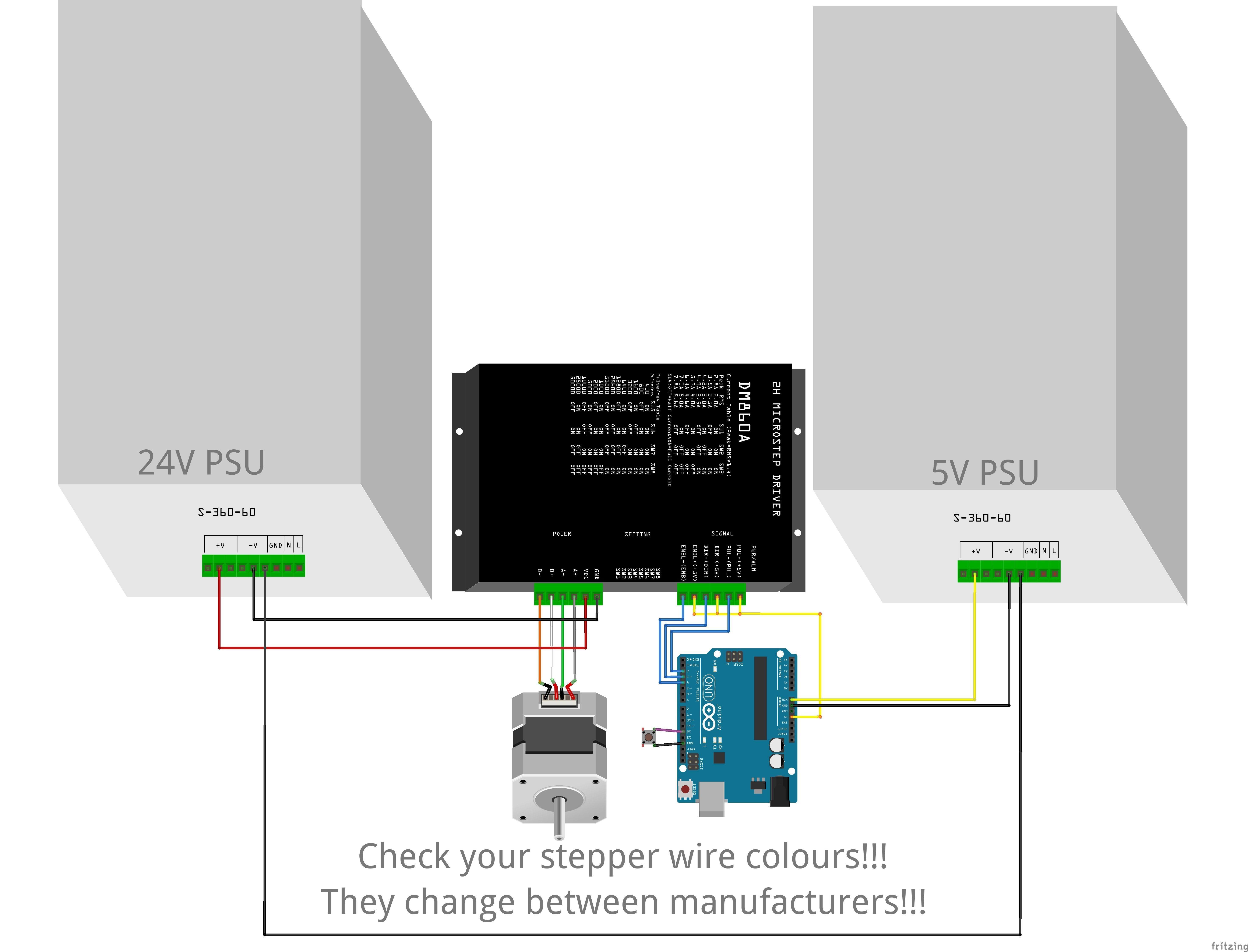

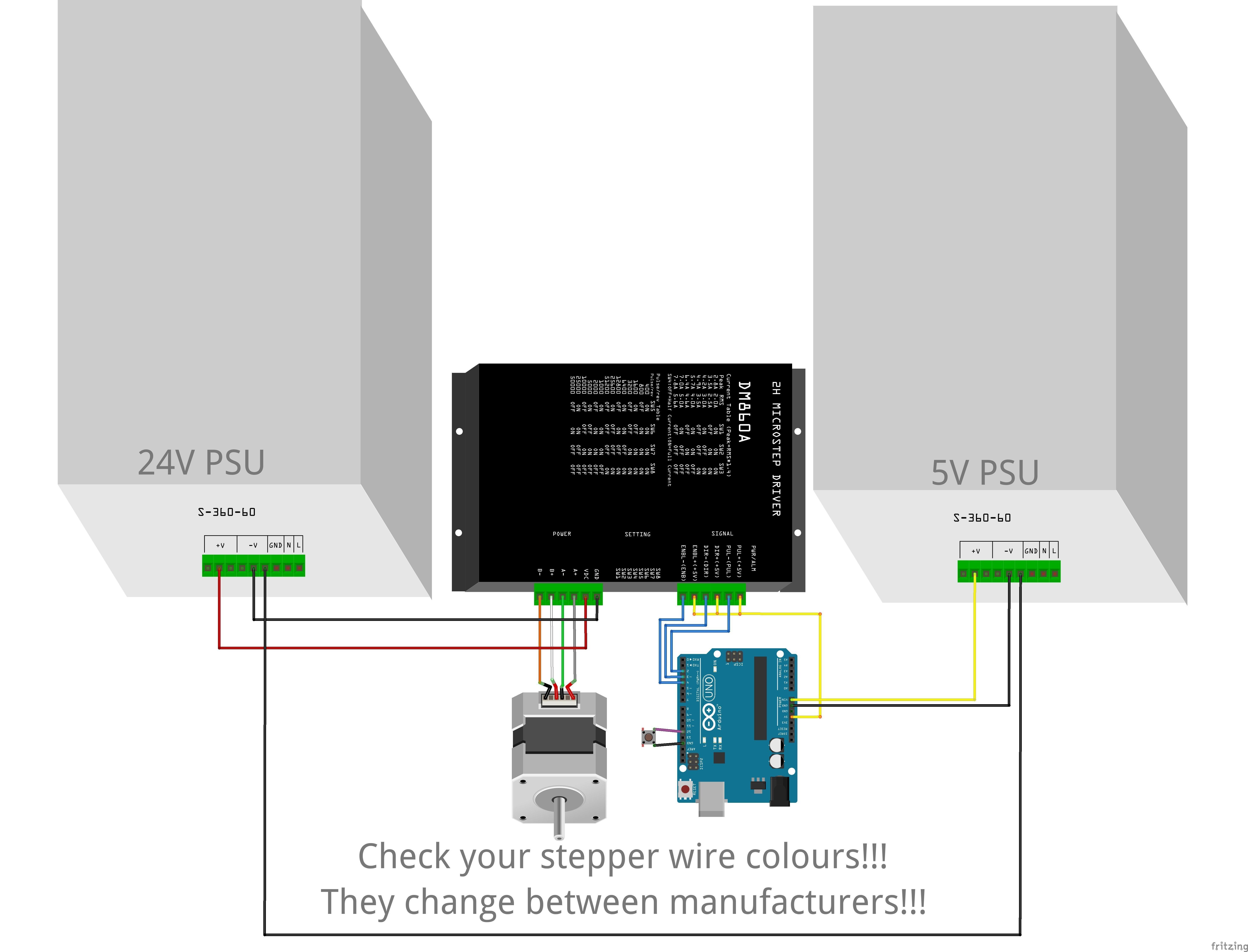

In addition to the printed parts, you are going to need a Nema17 stepper motor, stepper motor driver, and arduino (or similar pulse generator), some M3 fastenings and to make a steel or aluminium drive shaft part. A drawing is included for this. It can actually be cobbled together using off the shelf parts if you don't have access to a lathe to make a solid one.

The parts I use are;Stepper Motor - 17HS4401-DBX (40mm length, 5mm shaft diameter)Driver - TB6600For the rigid coupling, you can use a 3d printer soldid coupling, 5mm to 8mm (the coupling used to attach the 8mm lead screw to the stepper motor).

You can find our other projects, or else get in touch using the links below;

http://www.vikingmachinery.co.nz

Instagram; vikingmachinery

https://www.facebook.com/VikingMachineryNZ/