1/13

GRIFFFIIIIIIIIITHHHH

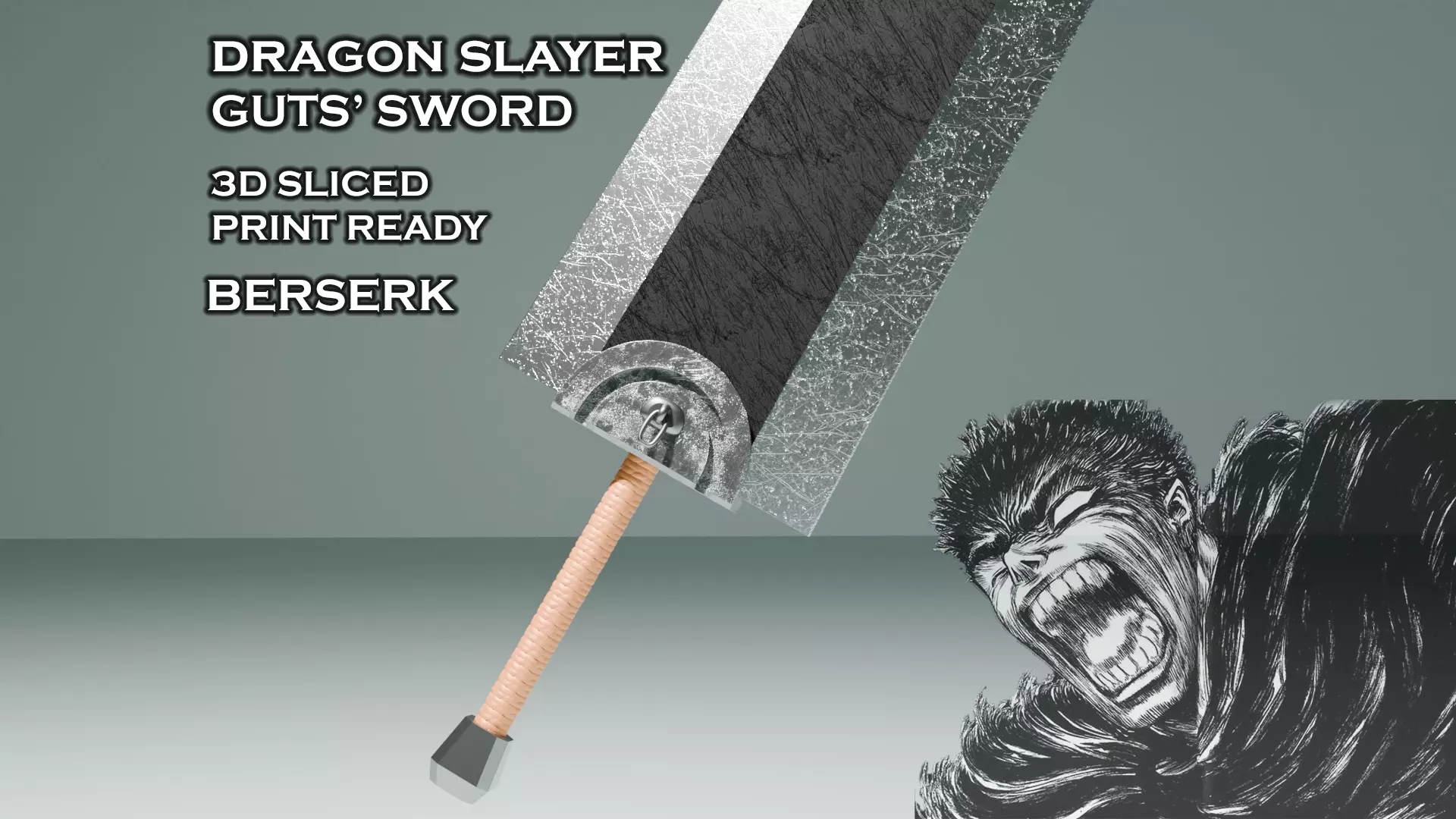

Dragon Slayer, the claymore of Guts from Berserk. One of the most iconic sword in the fantasy and manga world It is a highly detailed 1:1 model that is designed for 3D print. All details are real reliefs or engraves. Ideal for cosplaying, decorating etc.

--Dimensions--

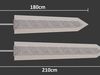

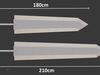

There is 2 versions of it. One of them has 210 cm original length in the manga, other one has 180cm size for easier carrying, less print material usage etc.

--Assembling—

There is a detailed assembling animation between the files. Assembling orders matters otherwise the parts wont fit together.

There is 4 version of the sword and 2 different length option fort he sword. One of the options has 210 cm originl size, other one has 180cm total size for easier carrying and less material usage. The other option is texture difference. One version of it has engraved and highly detailed metal texture on metal parts and fabric texture engrave on grip. Since all parts are modular, you can make your own version of the sword. For example, you can print the grip without texture and cover it with real fabric, but print the blade part with metal texture etc.

2 versions of the blade part: With scratched metal part engraved or smooth surface one2 versions of the handguard: With roughly forged metal texture engraved or smooth surface one.2 versions of the grip: Fabric texture engraved and smooth surface one.

All parts are sliced under 22 cm so you can print them with any 3D printer.There is a 3 different 10mm diameter metal rod slot inside of the sword. Without metal rod skeleton, it would break probably. For long version of the sword 2 of the side support rods has 150 cm length and main center rod has 205 cm length. For short version of the sword 2 of the side support rods has 117 cm length and main center rod has 171 cm length.

Don't forget to use a strong glue while assembling the partsThere is 0.5mm tolerance gap between sockets and plugs. İf you use a standart FDM 3D Printer with 0.4mm nozzle, it should be perfect fit. If it's a little loose, don’t worry. The main task of the plugs is to keep them stable and correctly oriented while you are pasting the parts.

--Recommended Printing Options--

I suggest that you have done tolerance and flow rate tests on your 3d printer before you start printing the model. I recommend minimum 3 walls for all parts. For grip part, i suggest more than 40% infill as well. It is a huge print and it costs probably 3kg+ material minimum in total we don't want it to be fragile. If the plugs and sockets have difficulties or do not enter each other, you could adjust your flow rate or could choose exclusive on slicing tolerance option.

If you have any questions or requests, feel free to message me. I'll gladly help as much as i can.

Don't forget to follow me on Instagram! You could reach me on DM and follow my content as well@random_but_qualityhttps://www.instagram.com/random_but_quality

Also you can check my youtube channel! I upload short timelapse and long painting videos of my modelshttps://www.youtube.com/@randombutquality161/featured

REVIEWS & COMMENTS

accuracy, and usability.