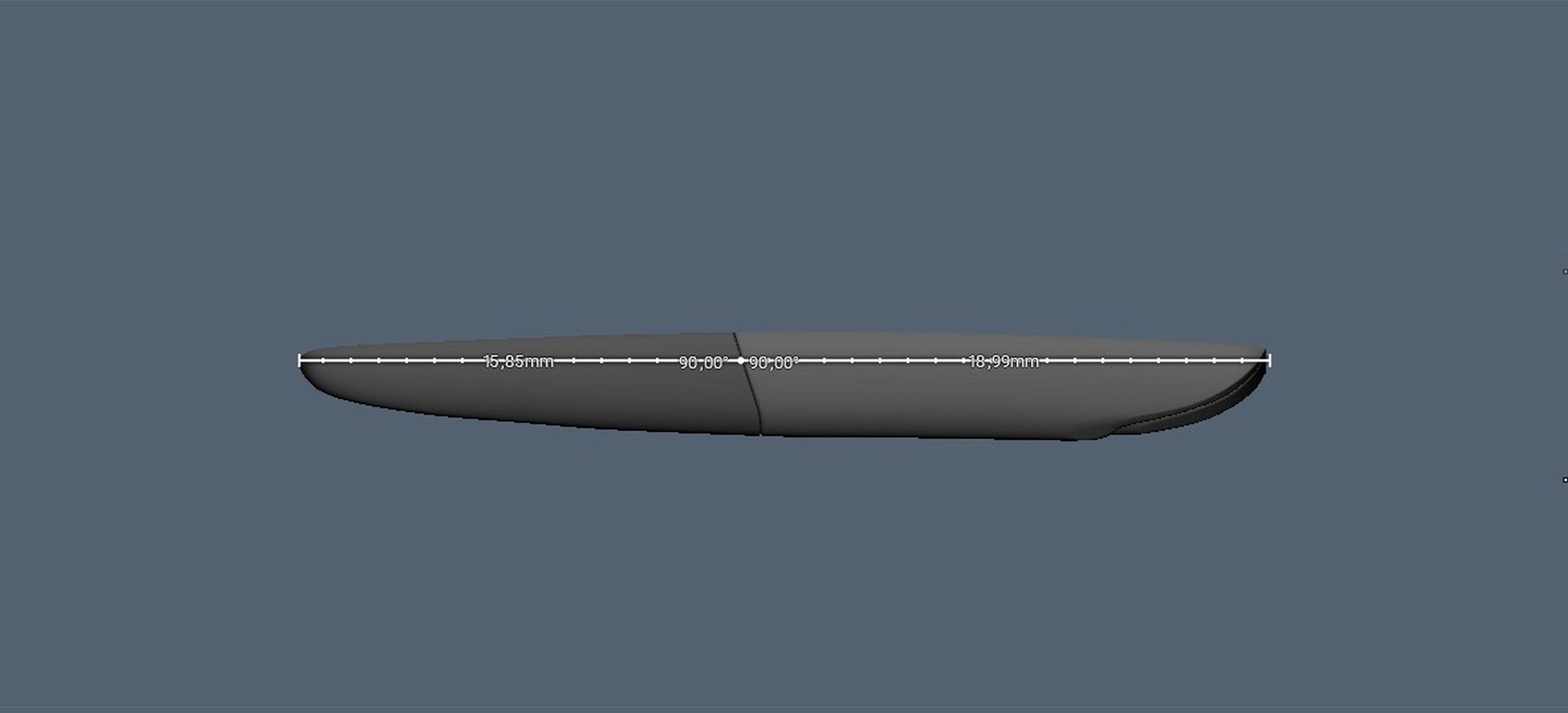

Nails Clips Model 3D print model

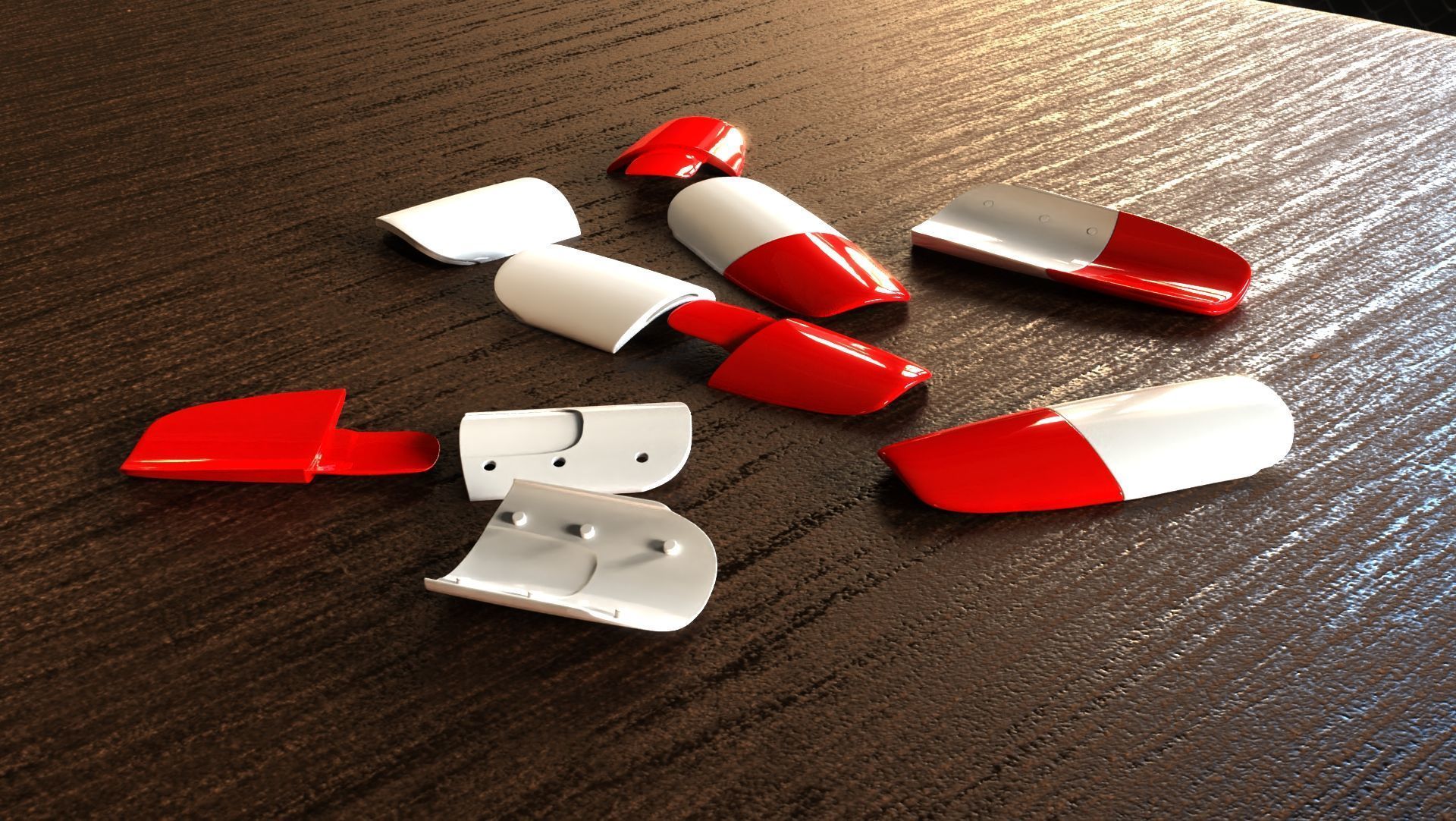

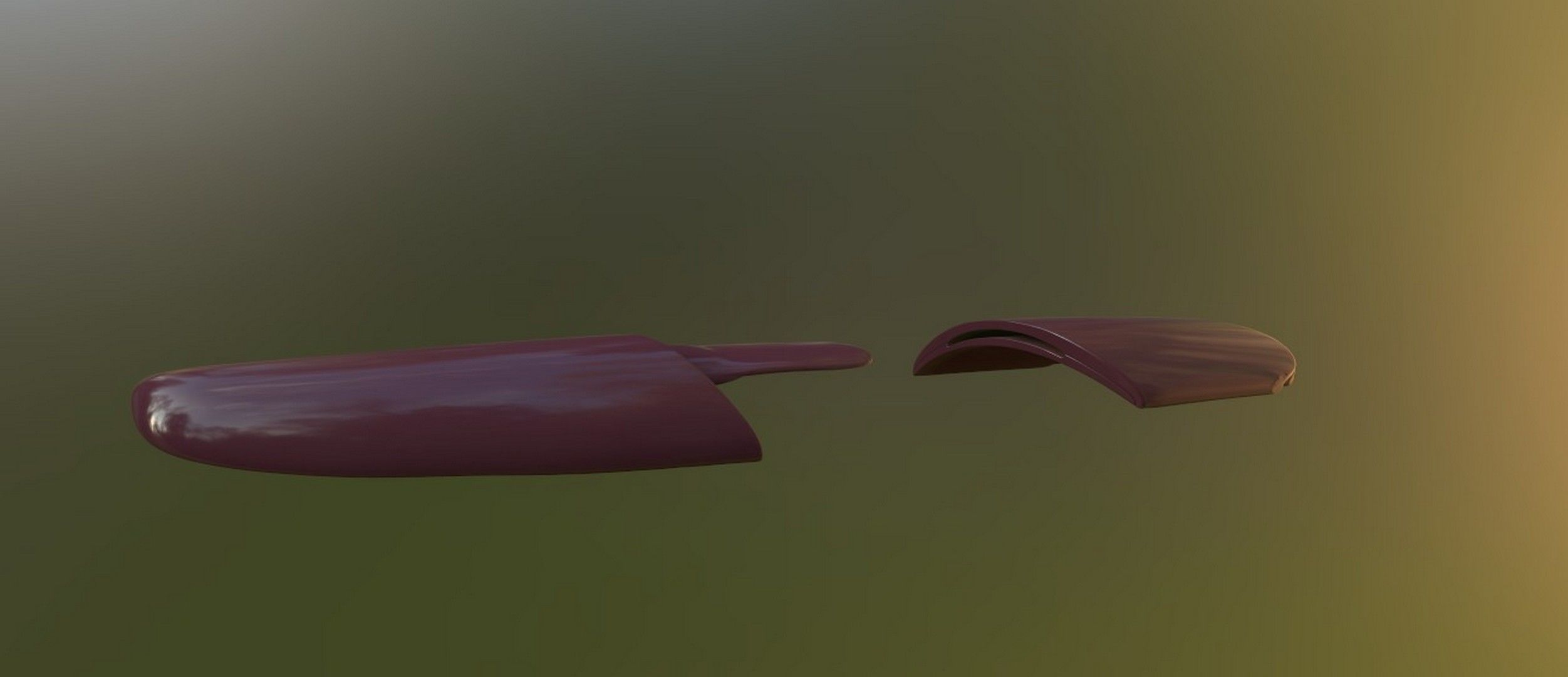

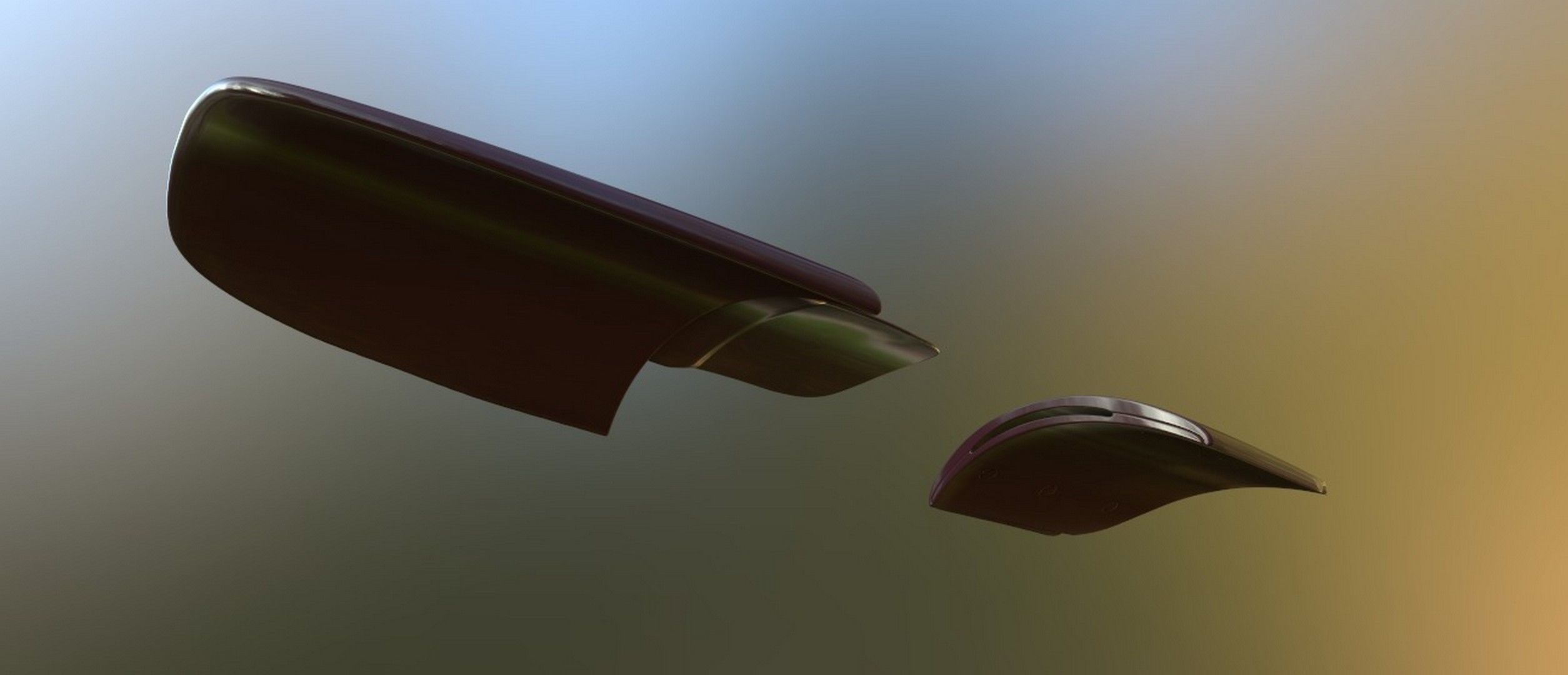

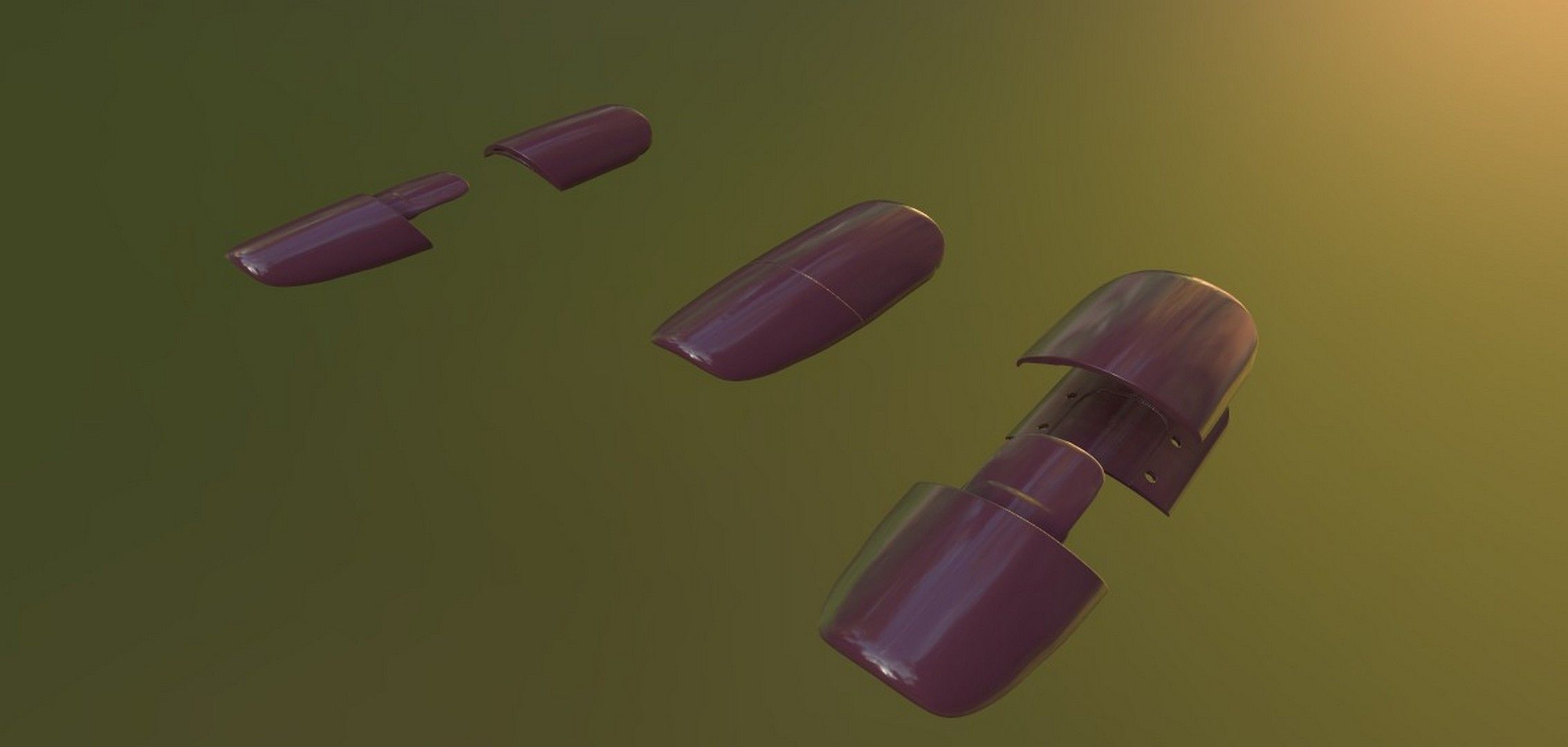

Model of nails - transformers. Consists of 3 parts for production. As a result, two parts that are conveniently transformed. The front part on a strong clip is inserted into the groove.

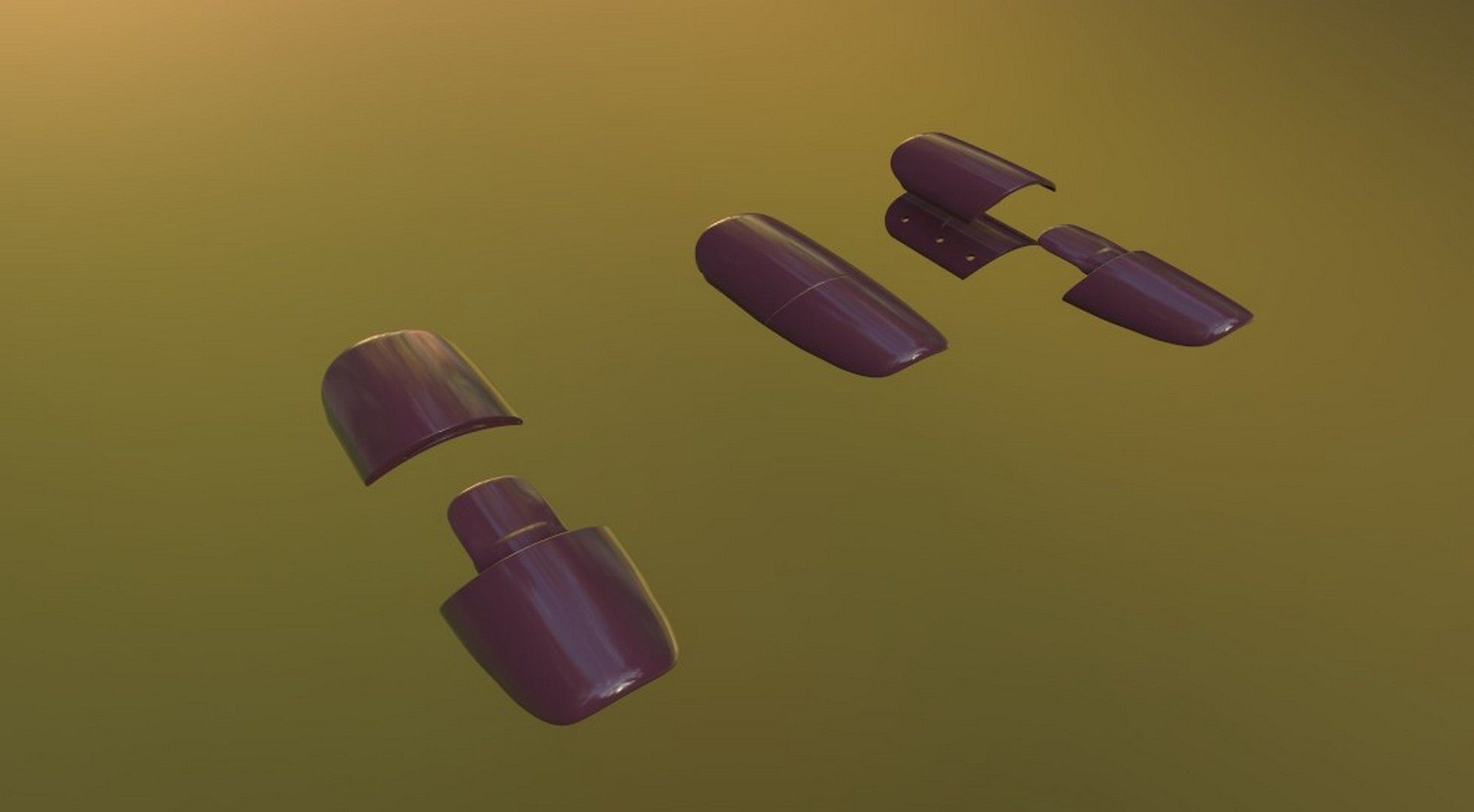

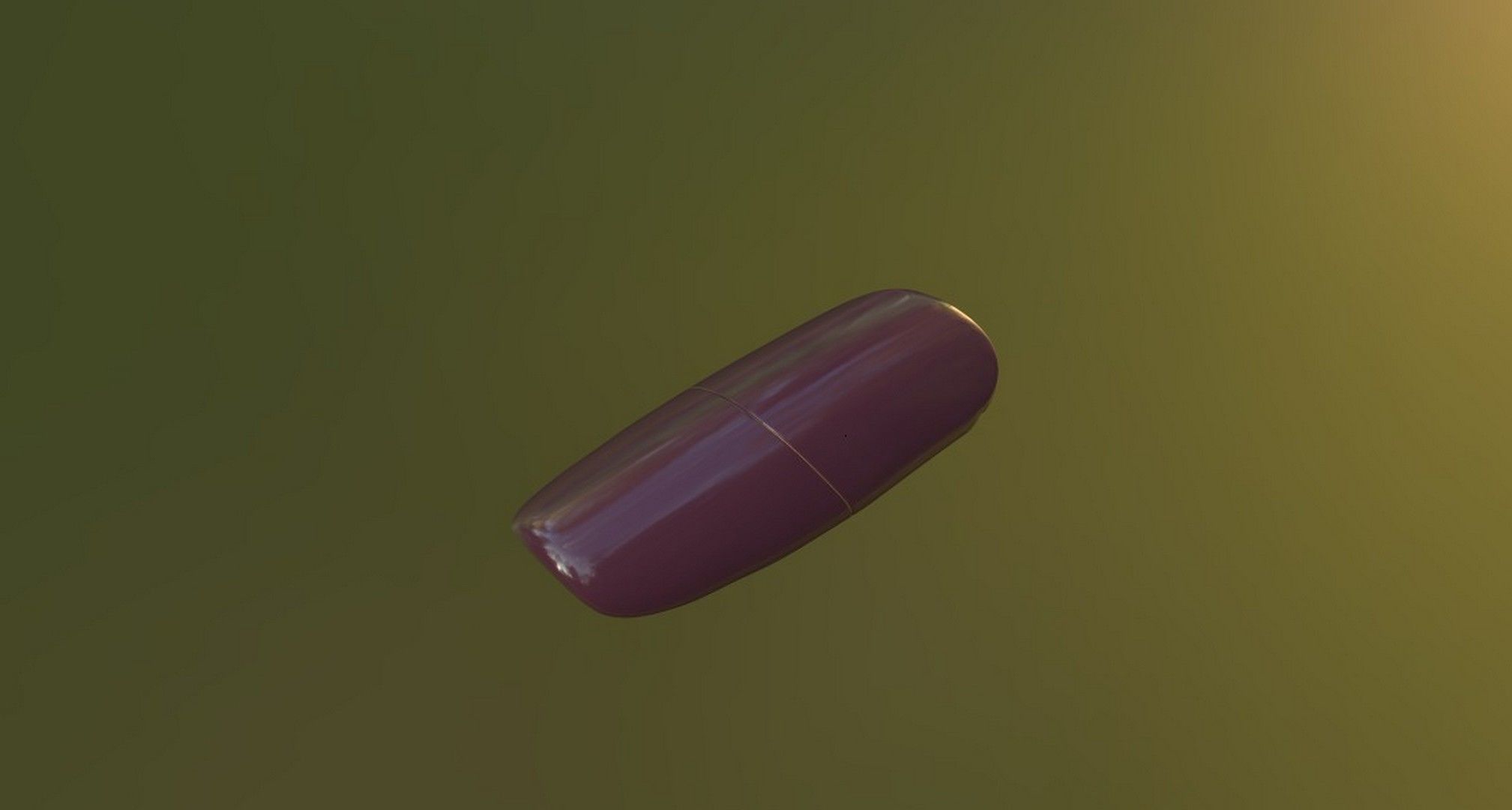

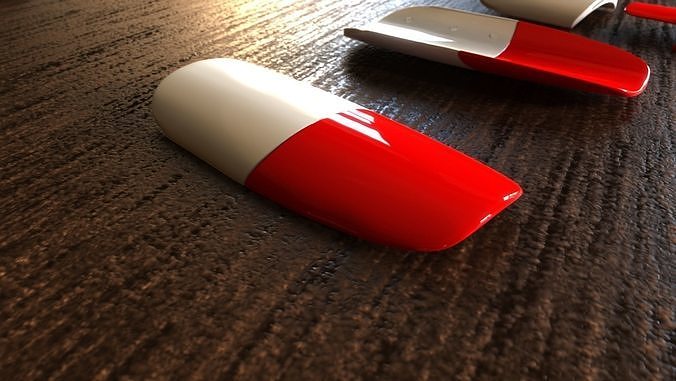

Overview of the ModelThe transformer nail model is a modular construction designed for versatility and ease of assembly. It consists of three main parts for manufacturing, which together create a sleek, durable, and functional final product. The design allows convenient transformation into two primary parts during use, with a secure mechanism that provides strength and stability.

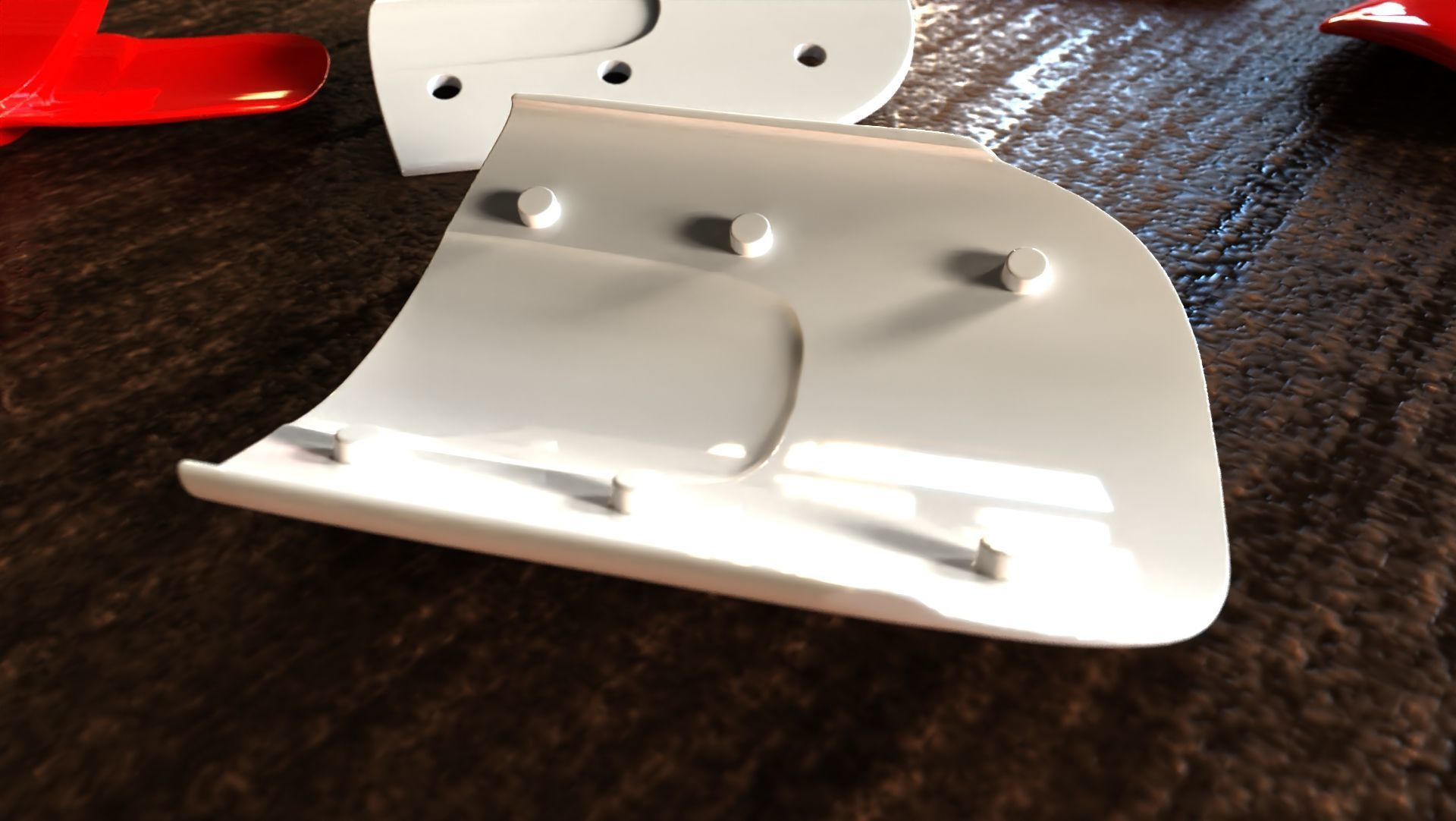

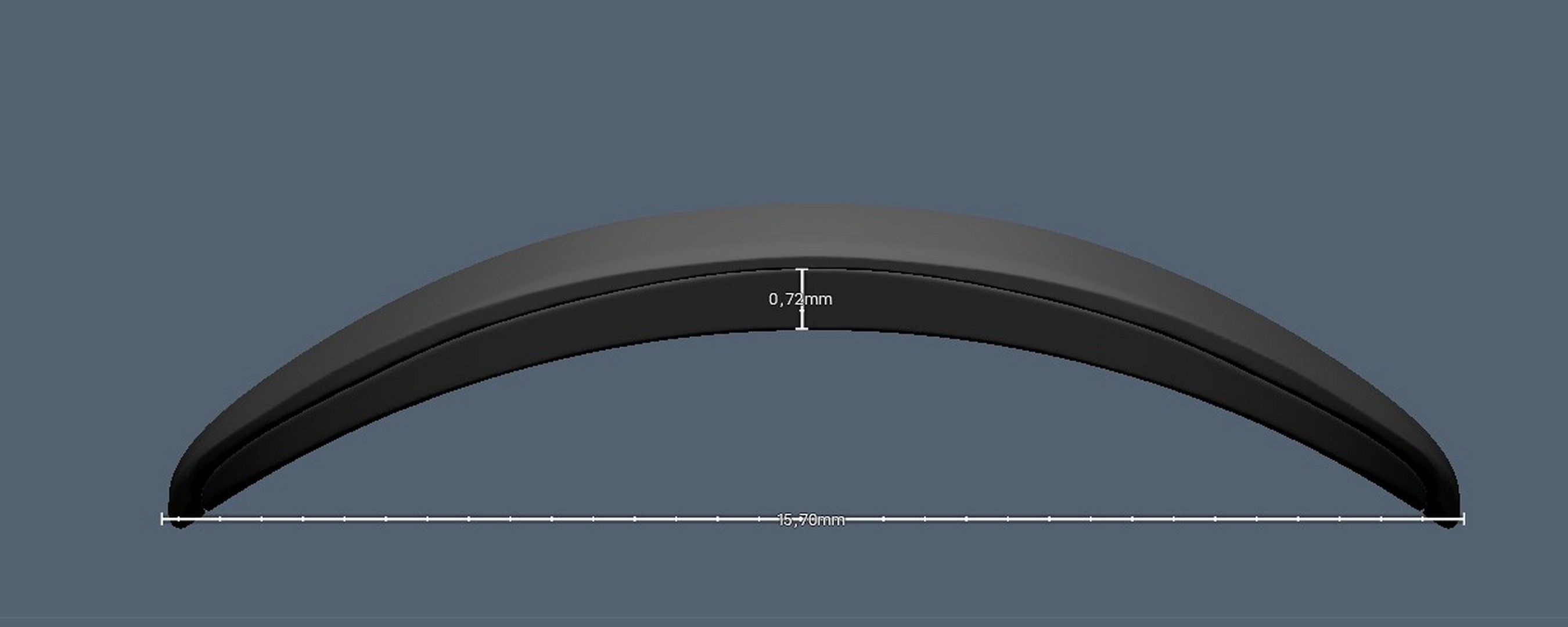

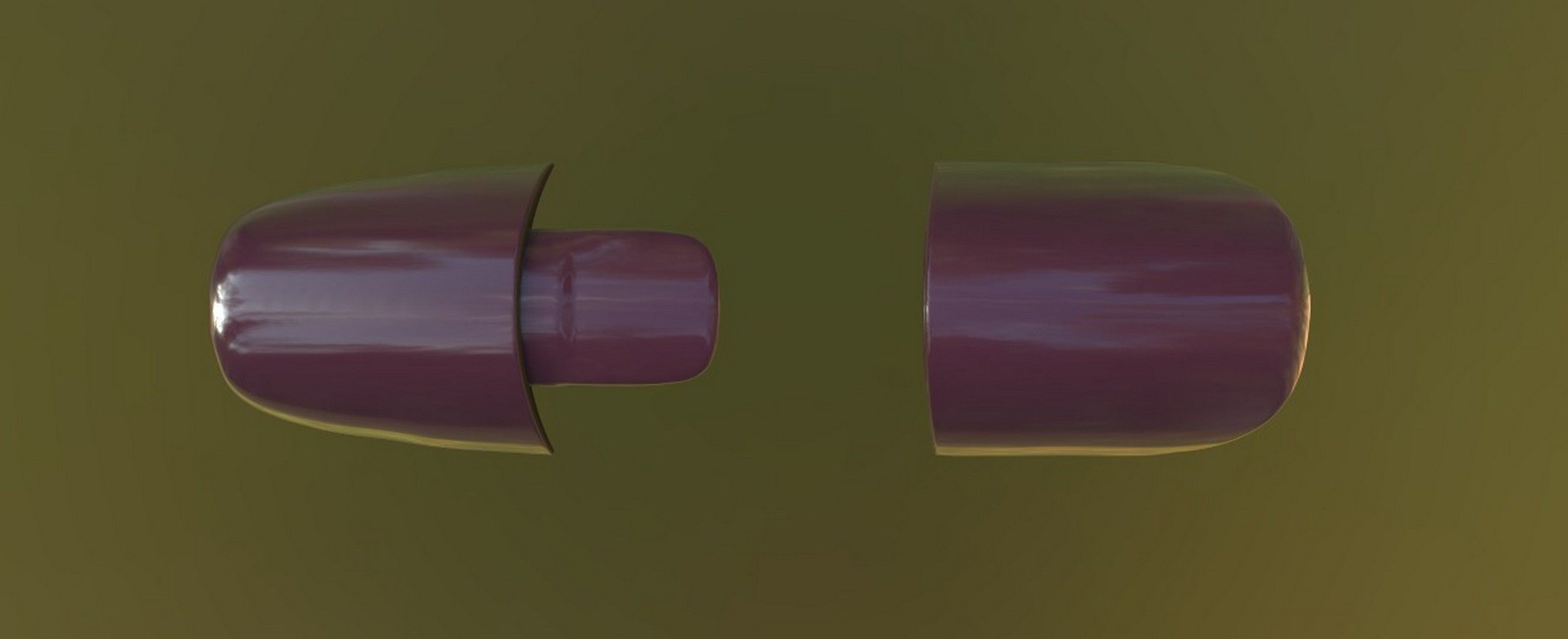

Component BreakdownPart 1: Base/BodyThe base forms the main structural support of the nail.Designed with precision grooves or slots that act as guides for the insertion of the front section.Made from durable materials optimized for high-strength performance under stress.Part 2: Front/Tip with Clip MechanismThe front section is attached using a robust clip system.The clip is engineered to snap securely into the groove of the base, holding the parts together during use.This clip design allows quick and easy transformation when separating or replacing the parts.Material considerations for this section focus on wear resistance and a firm grip.Part 3: Connector (Optional or Internal Component)The third part, depending on the design, may function as a stabilizer or locking mechanism.Ensures alignment and strength between the base and front section.In production, it can serve as a tool-less assembly solution, enhancing efficiency during manufacturing and user assembly.

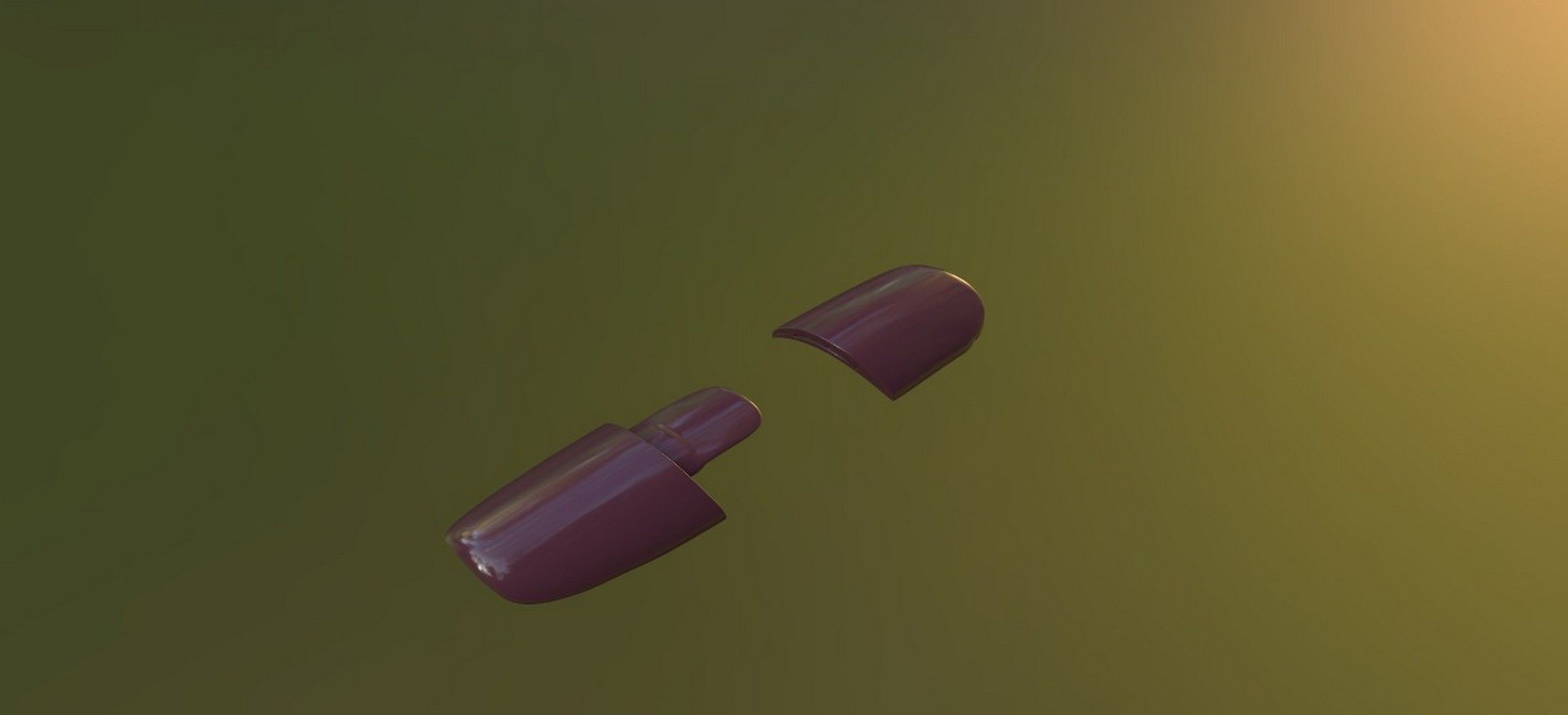

Transformation ProcessAssembly Mode:The front tip with the clip is inserted into the groove of the base. The design allows for a quick, tool-free connection with a firm locking action.

Transformation/Disassembly Mode:Applying pressure to a specific release point on the clip allows the front part to detach smoothly from the base, facilitating easy switching or maintenance.

- Key FeaturesStrong, Durable Construction:Optimized for strength and wear resistance, ensuring long-lasting performance.Quick Transformation Mechanism:The clip-and-groove system offers effortless assembly and disassembly.Precision Engineering:Designed with tight tolerances for secure fits and smooth operation.Modular for Production:The three-part construction simplifies manufacturing, improving efficiency and reducing production costs.ApplicationsIdeal for custom or modular nail designs that require interchangeable or flexible components.Suitable for high-precision industries where durability, ease of use, and reliability are critical.