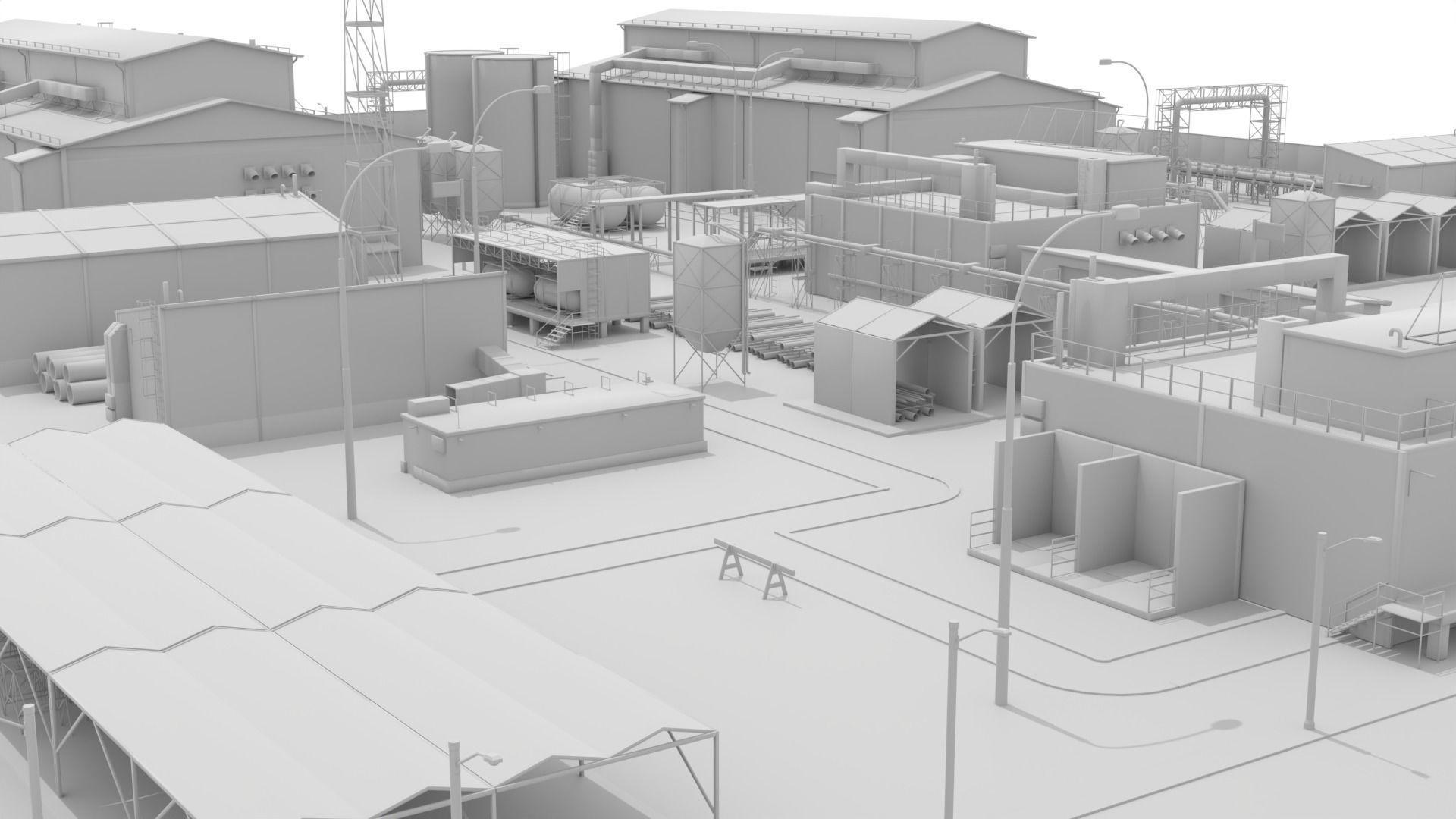

Refinery Storage and Post Production 3D model

A 3D model of a refinery sample storage system would depict a specialized facility designed to store and manage samples taken from various stages of the refining process. The storage system ensures proper organization, preservation, and accessibility of these samples for future analysis and reference.

The model would feature a sturdy and secure structure, often constructed with durable materials such as steel or concrete, to protect the samples from environmental factors and potential hazards. It would consist of multiple compartments or storage units, each equipped with shelves, racks, or drawers to store the sample containers in an orderly manner. The number and size of compartments may vary based on the capacity and requirements of the refinery.

The sample storage system would also incorporate various organizational features, such as labeling systems or digital inventory management, to keep track of the samples and facilitate easy retrieval. This may include barcode or RFID tagging to ensure accurate identification and tracking of individual samples within the storage facility.

To maintain the integrity of the samples, the 3D model may include environmental controls such as temperature and humidity regulation. This ensures that the samples are stored under optimal conditions, preventing degradation or contamination over time.

Additionally, the model may include safety features such as fire suppression systems, emergency exits, and security measures like access controls or surveillance cameras to protect the valuable samples and maintain compliance with safety regulations.

Overall, the 3D model of a refinery sample storage system would provide a comprehensive visualization of the facility, including its structural components, organizational systems, environmental controls, and safety measures, highlighting its critical role in preserving and managing refinery samples.