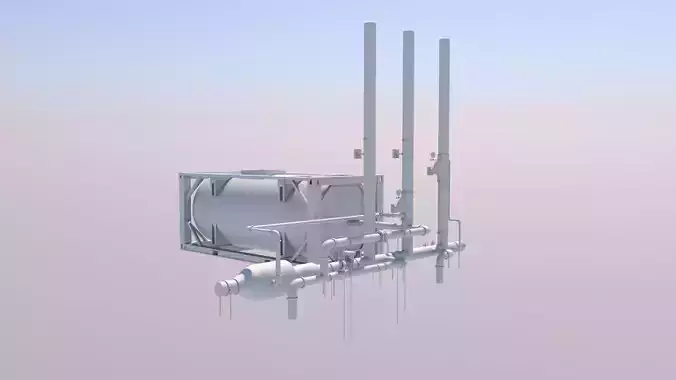

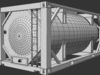

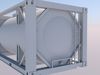

An ISO tank container is a cylindrical, stainless-steel tank surrounded by a protective framework, designed for the transportation of bulk liquids, gases, and powders. Here’s a detailed description to guide the 3D modeling of an ISO tank container:

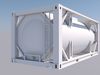

- Basic StructureTank Shell: Cylindrical shape, made of stainless steel, with hemispherical or conical ends (heads).Frame: A rectangular frame constructed from steel beams encases the tank. It typically has corner castings for lifting and securing during transportation.Dimensions: Standard lengths are 20 feet, but they also come in 10, 30, and 40 feet. Width is usually 8 feet, and height varies but is often around 8.5 feet.

- ComponentsManhole: Located on the top center of the tank for loading and inspection.Valves: Multiple valves for loading/unloading, pressure relief, and venting. Usually located on the top or at one end of the tank.Heating/Cooling Systems: Some tanks have external heating or cooling systems, often visible as external piping and control boxes.Insulation: Some tanks are insulated with materials like polyurethane, covered by a thin layer of stainless steel or aluminum.

- DetailingSupports: Internal supports or baffles to prevent sloshing of the liquid inside the tank.Ladders and Walkways: External ladders and walkways for access to the manhole and valves, often with safety railings.Placards: Safety and identification placards or plates indicating the type of cargo and safety information.Framework Detailing: Reinforced corners and edges, with intricate detailing where beams join.

- Materials and TexturesTank: Stainless steel with a polished or brushed finish.Frame: Steel beams, often painted in standard colors (e.g., white, grey, blue).Valves and Piping: Typically stainless steel or brass, with realistic textures for metal.Insulation Covering: Smooth metal, often aluminum or stainless steel.

- Modeling TipsReference Images: Use multiple reference images from different angles to capture the correct proportions and details.Accurate Dimensions: Ensure the tank and frame dimensions conform to ISO standards.Subdivision Modeling: Use subdivision surface modeling techniques for smooth, curved surfaces like the tank body.Boolean Operations: Employ boolean operations for cutting out details such as manholes, valves, and supports.

- SoftwarePreferred Software: Blender, Maya, 3ds Max, or any other advanced 3D modeling software that supports detailed modeling and texturing.By incorporating these details and considerations, you can create a highly accurate and realistic 3D model of an ISO tank container suitable for simulations, animations, or virtual environments.