EN1092-1 Type 1 Plate Flanges for Welding 3D model

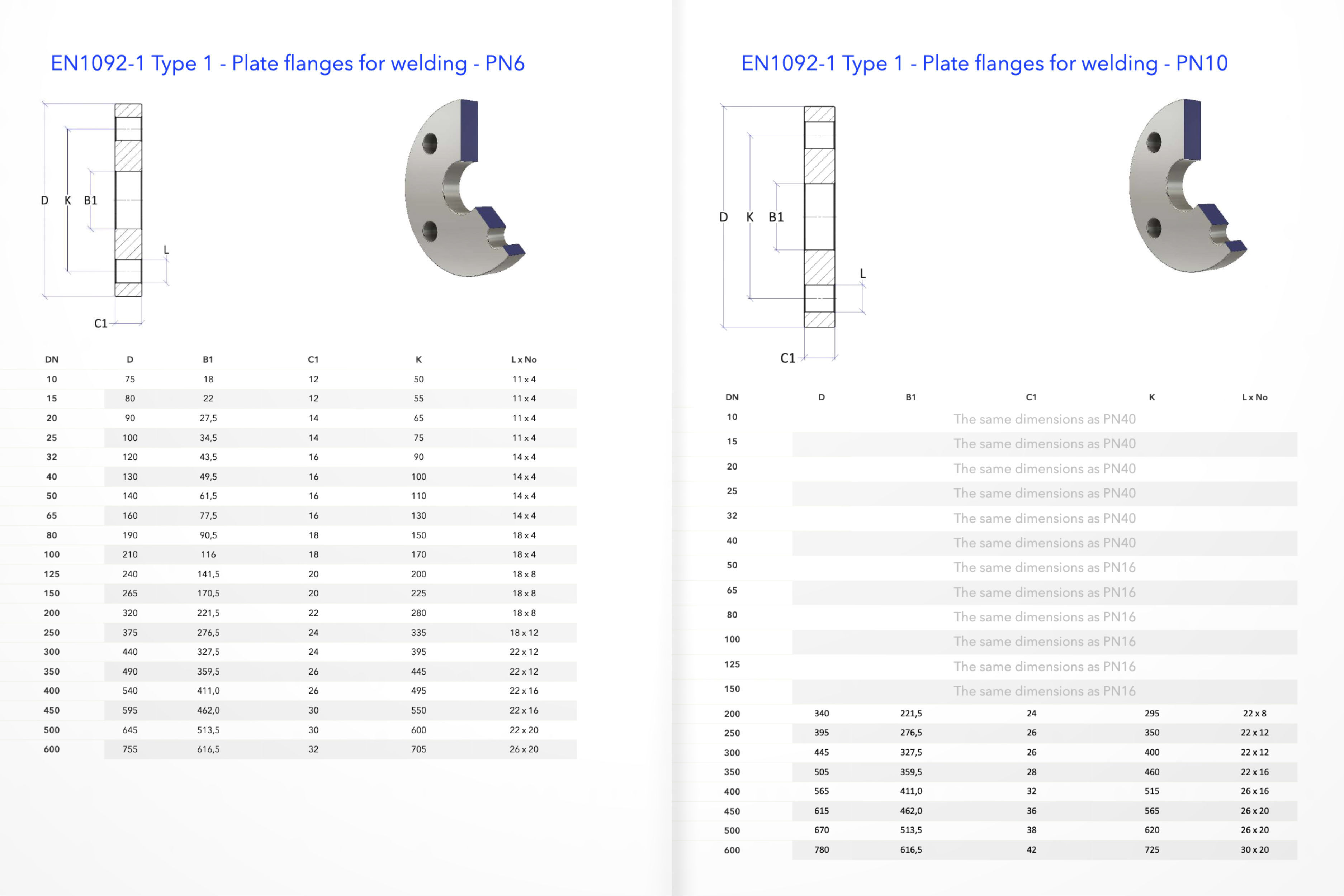

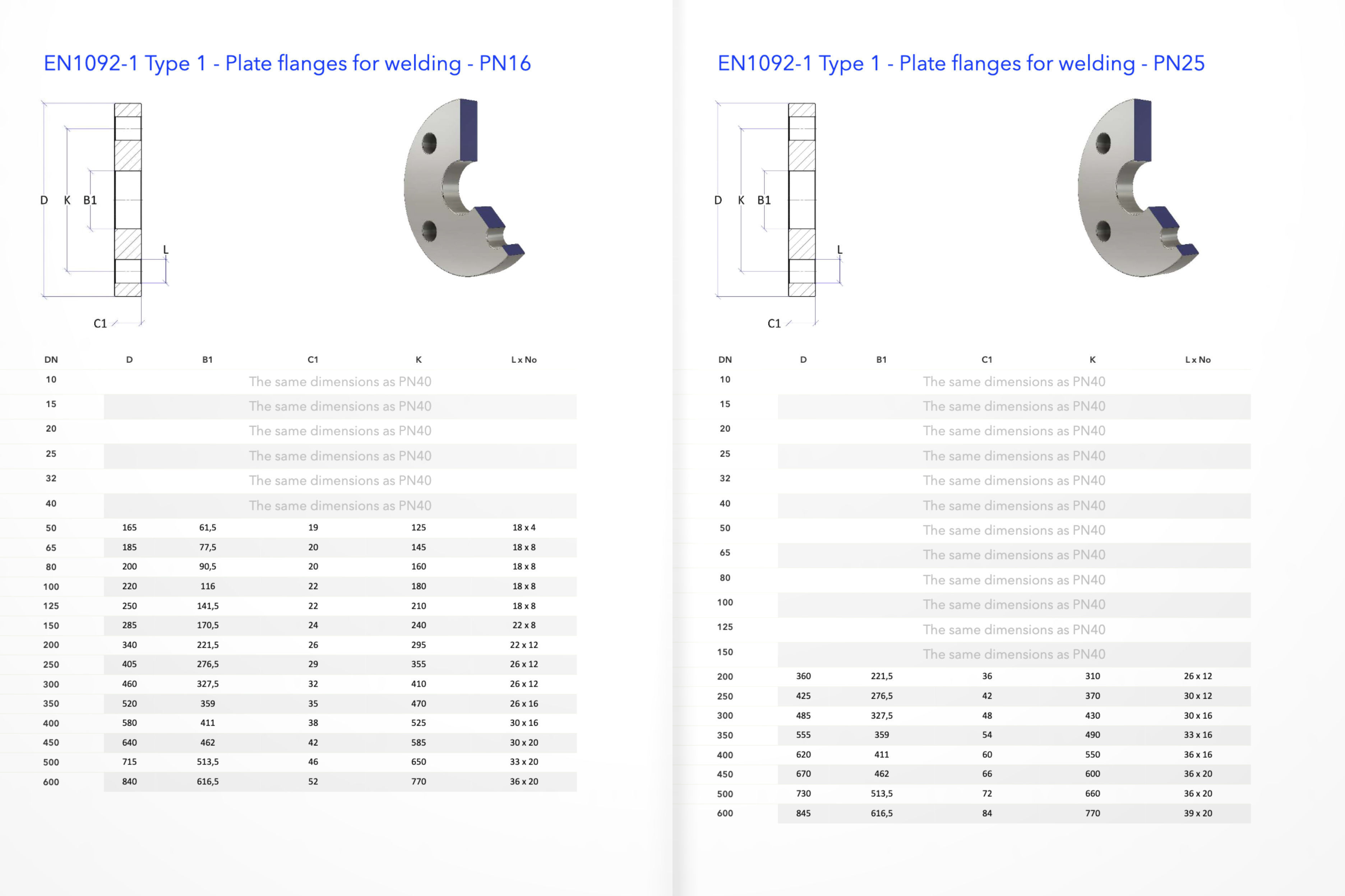

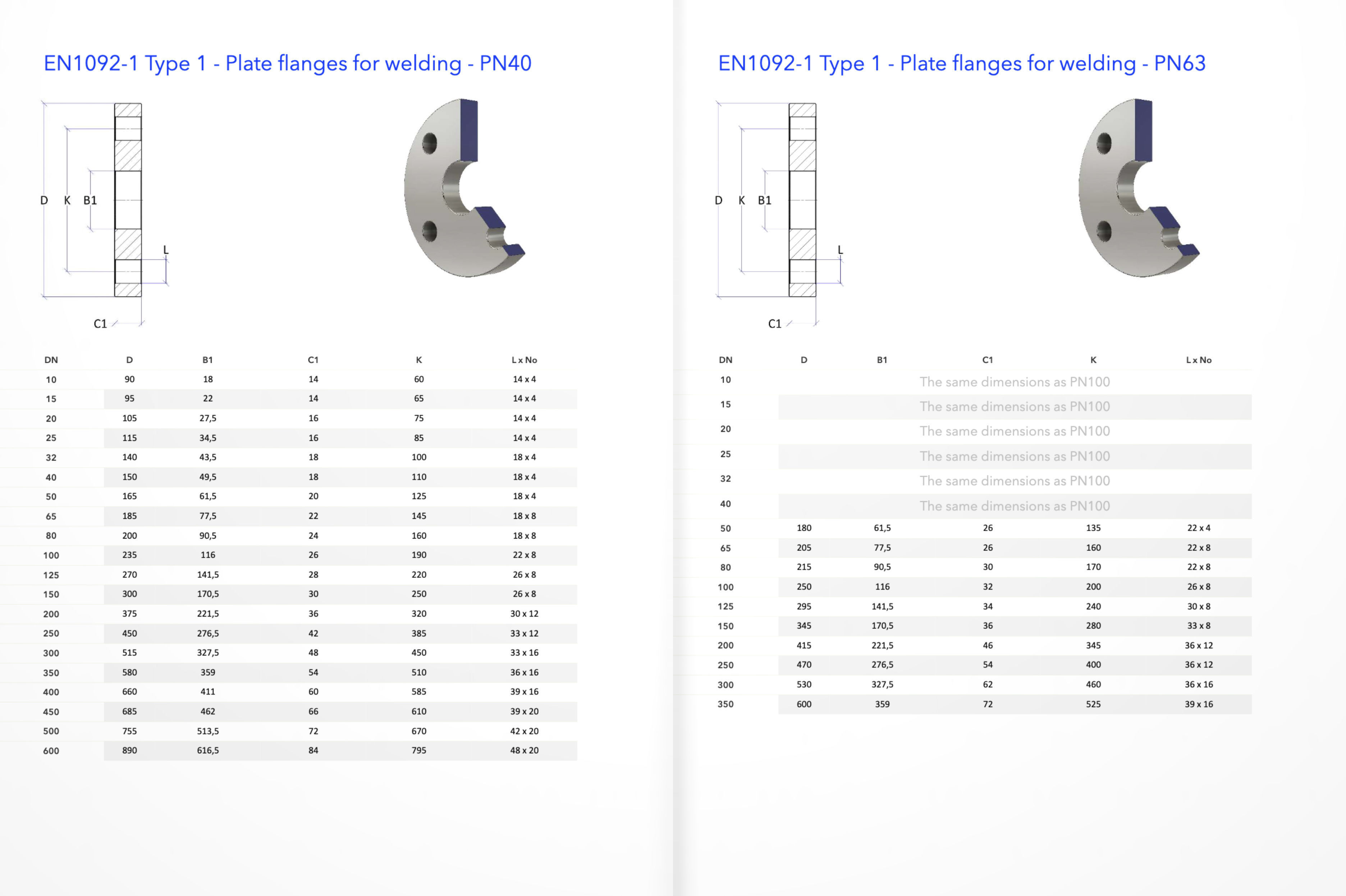

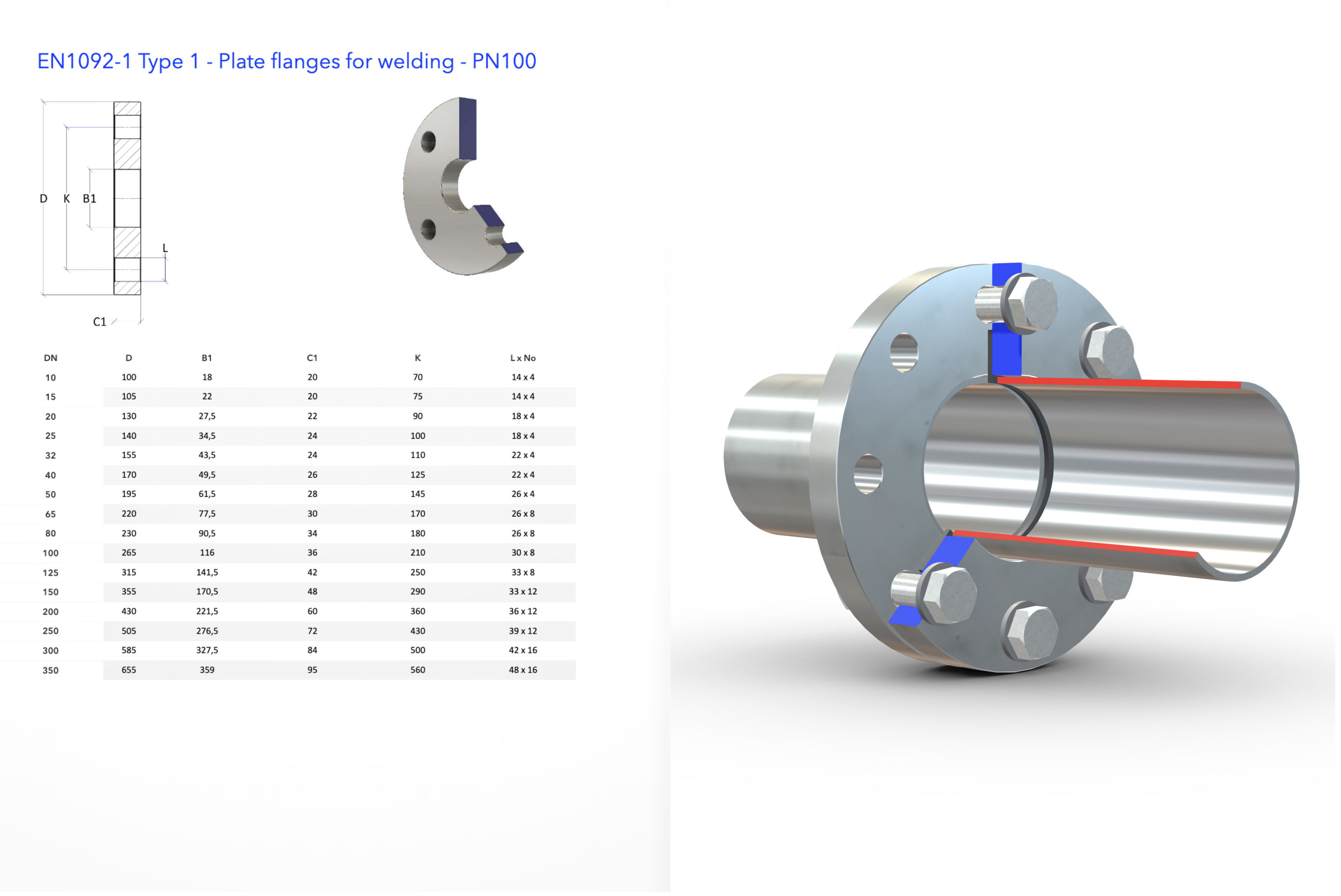

A COMPLETE COLLECTION THAT COVERS ALL POSSIBLE DIAMETERS AND PRESSURE RATINGS

About EN1092-1-1 Plate Flanges for Welding

In the intricate network of piping systems, one of the unsung heroes is the EN1092-1-1 plate flange. These components are part of the European standard EN1092-1, which defines the specifications, materials, and technical requirements for various types of flanges. EN1092-1-1, often referred to simply as the plate flange, is a vital element in creating secure, durable connections in piping systems. This article delves into the features, applications, and advantages of EN1092-1-1 plate flanges, shedding light on their critical role in industries worldwide.

Understanding EN1092-1-1 Plate Flanges

EN1092-1 is a comprehensive European standard governing the use of flanges in piping systems. It encompasses several flange types, each designed for specific applications. EN1092-1-1 plate flanges are notable for their flat, circular design, which makes them perfect for welding to pipes, valves, and other equipment, creating robust connections that are essential for the efficient functioning of pipelines.

Key Features of EN1092-1-1 Plate Flanges

- Flat Design: The defining feature of the EN1092-1-1 plate flange is its flat, circular shape. This design is ideal for welding as it ensures a smooth, even surface for the weld joint, minimizing stress concentration points and ensuring a tight seal.

- Hole Alignment: Plate flanges come with evenly spaced holes around their circumference. These holes are intended for bolting the flange to a companion flange, valve, or piece of equipment, enhancing the structural integrity of the connection.

- Standard Compliance: EN1092-1-1 plate flanges adhere to the rigorous European standard, ensuring that they meet specific criteria for design, materials, and dimensions. This standardization makes them compatible with other flanges and components in the system.

Applications of EN1092-1-1 Plate Flanges

EN1092-1-1 plate flanges are found in a broad spectrum of industries, thanks to their adaptable design and exceptional welding capabilities. Notable applications include:

- Petrochemical Industry: Plate flanges are widely used in refineries and chemical processing plants to connect pipes and equipment. The secure welded connections are crucial for handling corrosive and high-pressure substances.

- Power Generation: Power plants, including both thermal and nuclear facilities, rely on plate flanges for joining various pipes and components. The durability and stability of these connections are vital in power generation systems.

- Water and Wastewater Treatment: Water treatment plants make extensive use of plate flanges to connect pipes and valves. These flanges withstand the rigors of water treatment processes, such as filtration, chemical dosing, and distribution.

- Manufacturing and Construction: The versatility of plate flanges extends to manufacturing facilities and construction projects, where they provide a solid and leak-resistant connection for diverse applications, from HVAC systems to conveyor belts.

Advantages of EN1092-1-1 Plate Flanges

- Exceptional Welding Properties: The flat design of plate flanges ensures a well-distributed weld seam, reducing stress points and enhancing the integrity of the connection. Welding plate flanges is a straightforward process, making them a preferred choice for many professionals.

- Uniform Hole Alignment: The evenly spaced holes around the flange's circumference enable secure bolting to other components. This alignment simplifies installation and enhances the structural integrity of the connection.

- Standardized Reliability: EN1092-1-1 plate flanges conform to the EN1092-1 standard, ensuring uniformity and compatibility with other system components. This standardization simplifies procurement and maintenance, reducing the risk of mismatched or incompatible parts.

- Versatile Applications: These flanges are suitable for a wide range of industries and are adaptable to different operating conditions, making them a versatile solution for many applications.

Conclusion

EN1092-1-1 plate flanges are unsung heroes in the world of piping systems, known for their efficiency, reliability, and adaptability. Their flat, circular design, uniform hole alignment, and compliance with the EN1092-1 standard make them indispensable in a variety of industries. From the demanding environments of petrochemical plants to the vital water treatment facilities and the vast world of manufacturing and construction, EN1092-1-1 plate flanges are the backbone of robust, leak-resistant connections. These flanges play a crucial role in ensuring the integrity of piping systems, demonstrating their enduring importance in industries worldwide.

File Formats:

- .f3d - Fusion 360

- .stp - Autodesk Inventor, Solidworks, Solid Edge and more...