ASME B16-5 Welding Neck Flanges - 150Lbs and 300Lbs - CAD Files 3D model

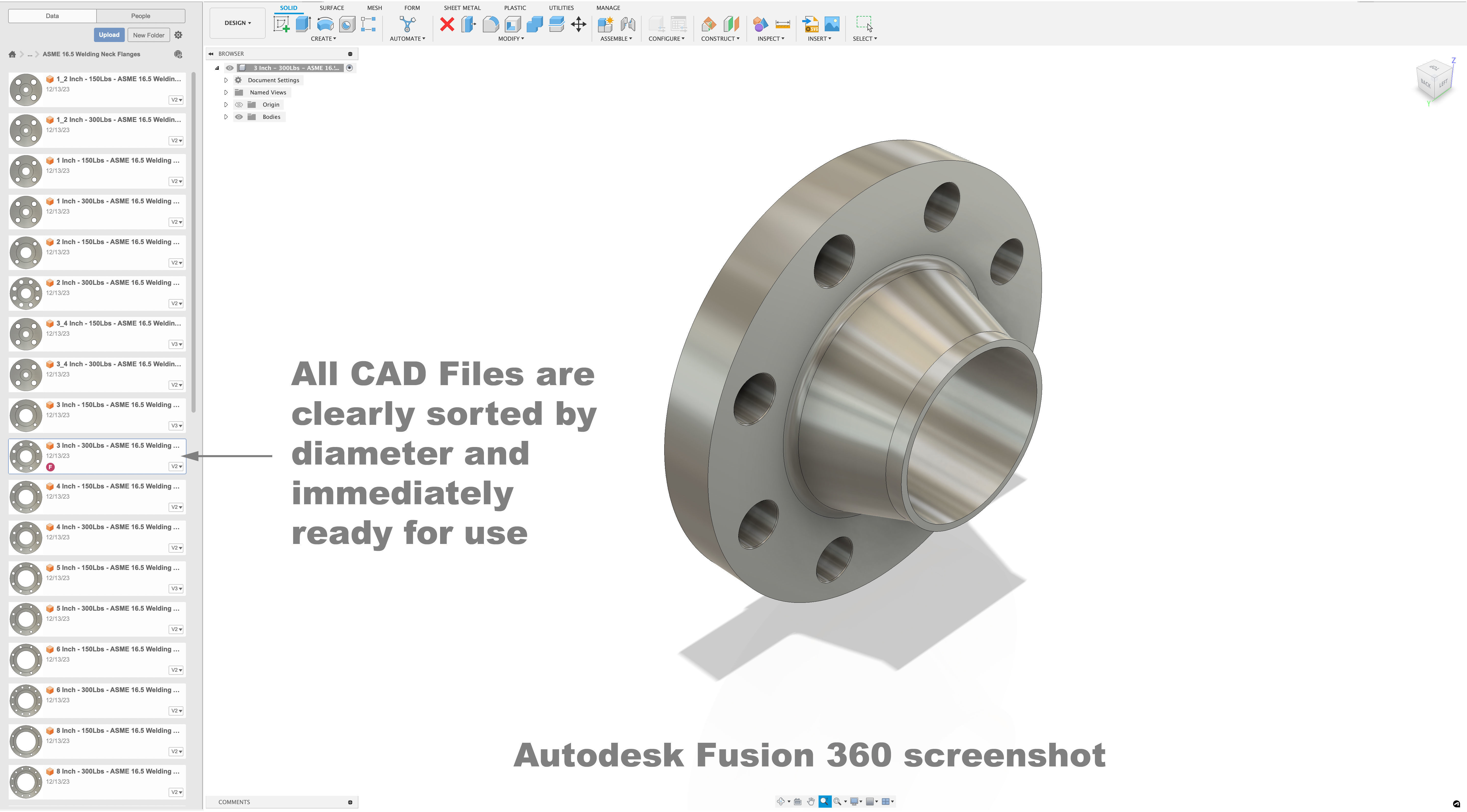

IN THIS 3D CAD COLLECTION:

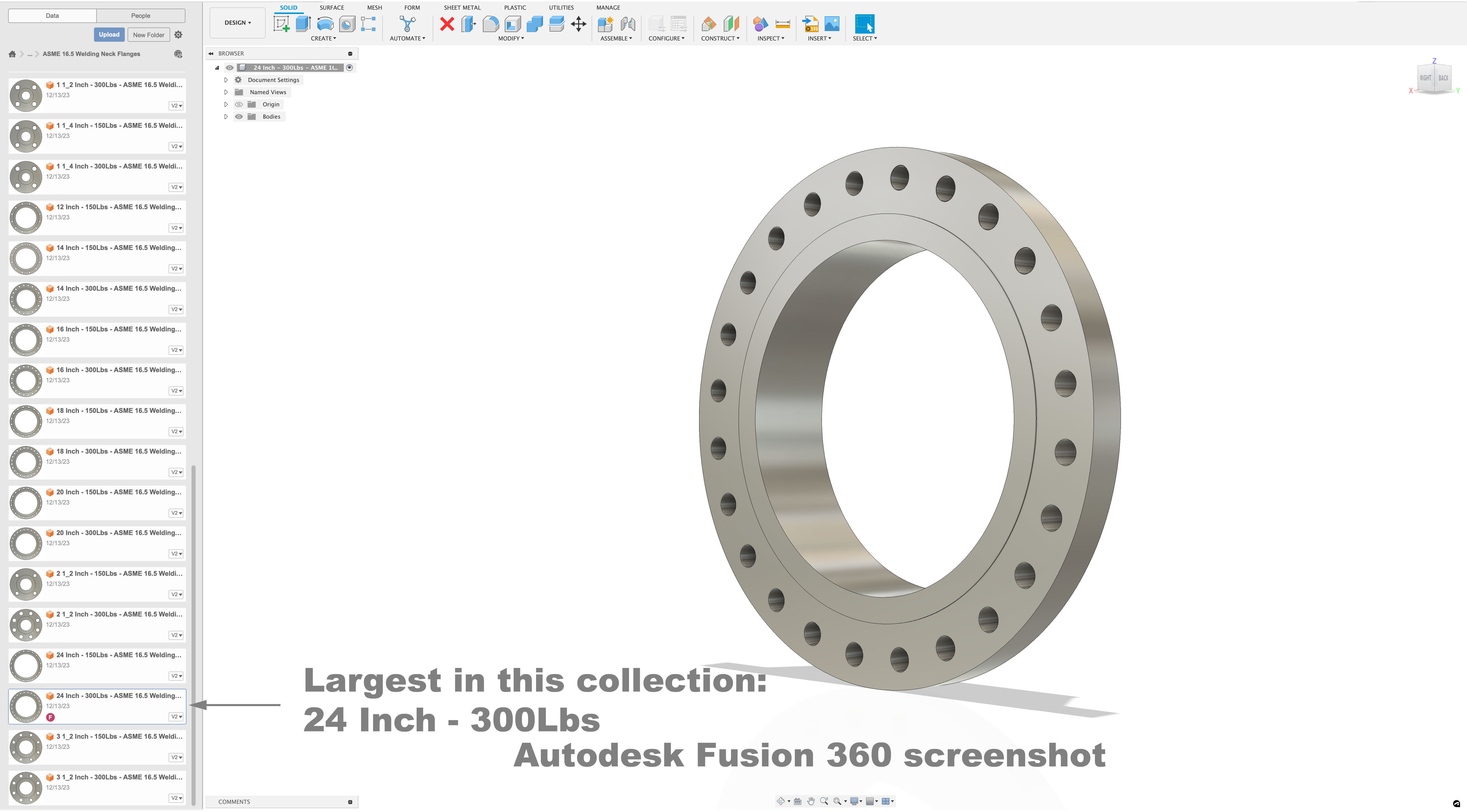

- 40 Different 3D CAD files.

- F3D and STEP file types.

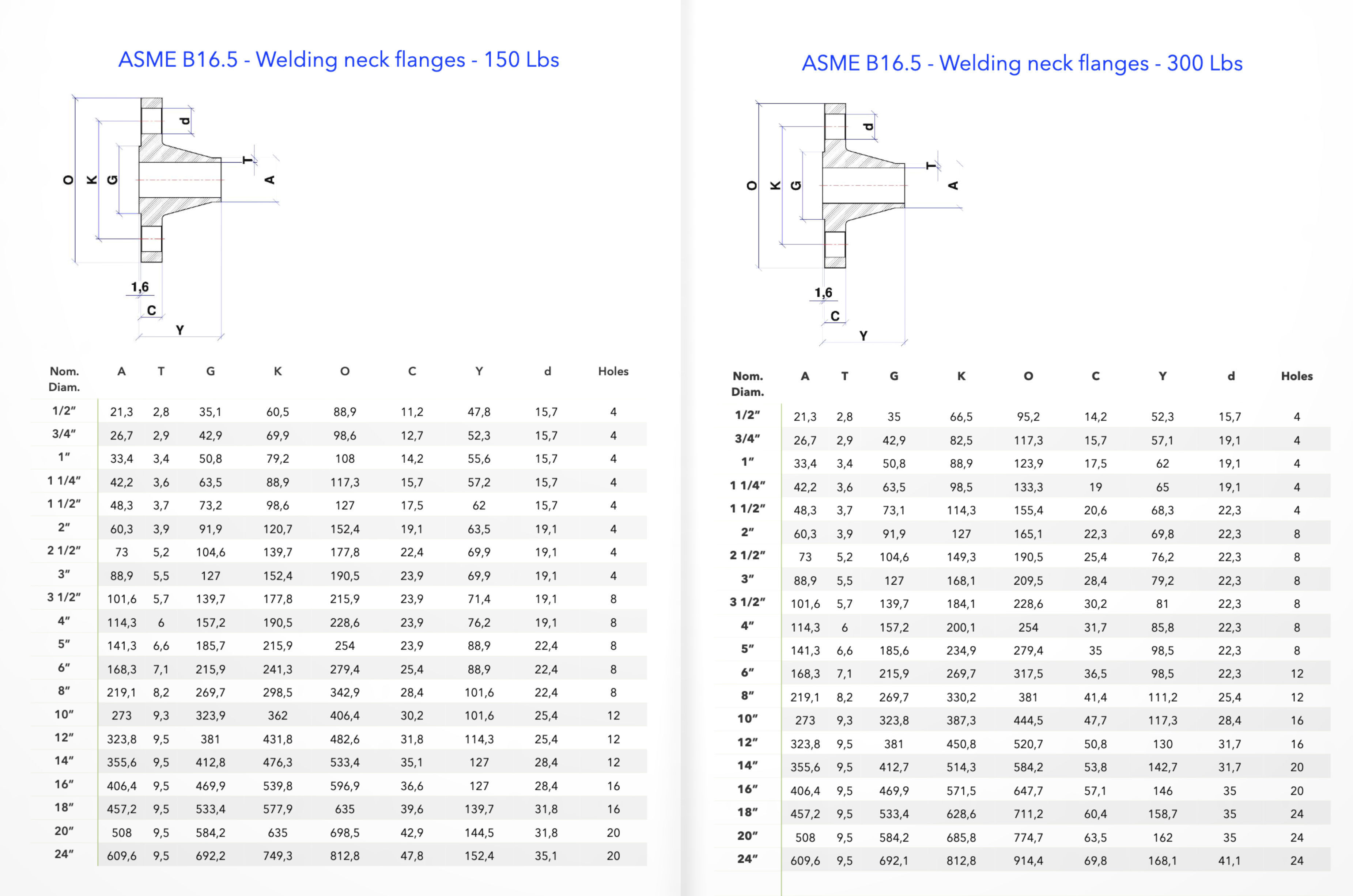

- Welding neck flanges according to the ASME B16.5 Standard

- Diameters 1/2 Inch up to 24 Inch

- Pressure classes: 150Lbs and 300Lbs

THE FILE TYPES:

- .step (STP): This file type is often used for exchanging 3D models and is compatible with most CAD software, such as SolidWorks, Inventor, AutoCAD, and Fusion 360.

- .f3d (Fusion 360): Suitable specifically for Autodesk Fusion 360 users, it allows you to import the models directly into this popular design application.

ABOUT ASME B16.5 WELDING NECK FLANGES:

ASME B16.5 Welding Neck Flange: An Overview of Applications and Advantages

An essential component in piping systems is the flange, and a specific variant widely used in various industries is the ASME B16.5 Welding Neck Flange. Standardized according to the American Society of Mechanical Engineers (ASME) B16.5 standards, this flange is extensively employed due to its specific design and advantages.

What is an ASME B16.5 Welding Neck Flange?

The ASME B16.5 Welding Neck Flange is a type of flange with a cylindrical neck that is welded to the pipe. This neck ensures a smooth transition from the flange to the pipe, reducing the likelihood of stress concentrations and local corrosion. The flange itself has bolt holes, allowing it to be secured to an opposing flange with bolts, ensuring a strong and secure connection in piping systems.

Applications of ASME B16.5 Welding Neck Flanges:

This flange is widely used in various industries, including the chemical industry, petrochemicals, oil and gas extraction, power plants, and more. The ASME B16.5 Welding Neck Flange is often applied in high-pressure and high-temperature environments, where reliability and durability are crucial.

Advantages of ASME B16.5 Welding Neck Flanges:

- Strength and Reliability: The weld neck reinforces the connection between the flange and the pipe, enhancing the overall strength and reliability of the system.

- Resistance to Stress: The streamlined transition of the neck reduces stress concentrations, making the flange more resistant to stress and torsional forces.

- Safety: Bolt holes provide secure attachment, crucial in high-pressure and high-temperature applications, contributing to the overall safety of the piping system.

- Ease of Installation: The ASME B16.5 Welding Neck Flange is easy to install and maintain, making it a cost-effective choice for many applications.

- Durability: The design and use of high-quality materials make this flange durable and resistant to corrosion, extending the lifespan of the piping system.