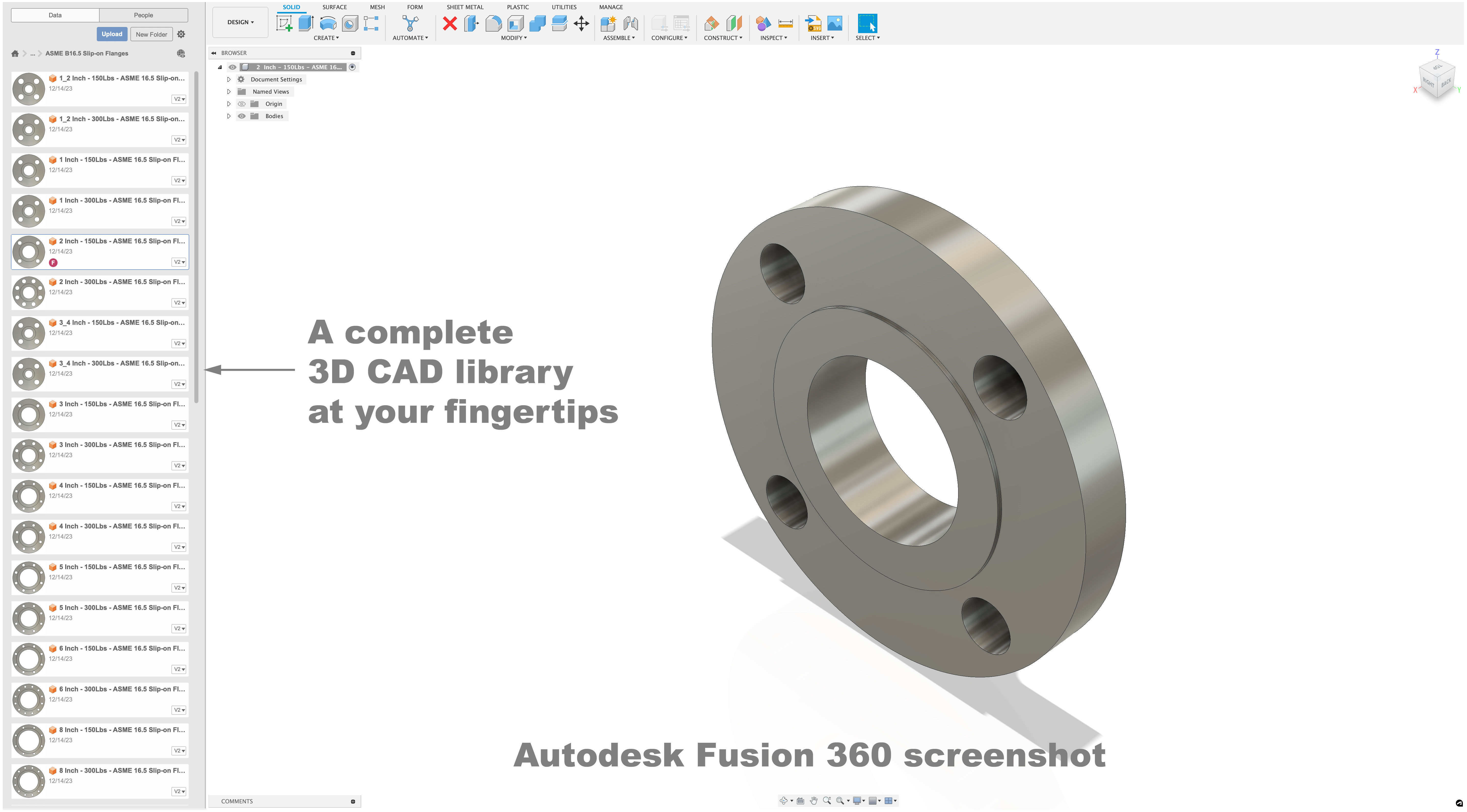

ASME B16-5 Slip-on Flanges - 150Lbs and 300Lbs - CAD Files 3D model

IN THIS 3D CAD COLLECTION:

- 40 Different 3D CAD files.

- F3D and STEP file types.

- Slip-on flanges according to the ASME B16.5 Standard

- Diameters 1/2 Inch up to 24 Inch

- Pressure classes: 150Lbs and 300Lbs

THE FILE TYPES:

- .step (STP): This file type is often used for exchanging 3D models and is compatible with most CAD software, such as SolidWorks, Inventor, AutoCAD, and Fusion 360.

- .f3d (Fusion 360): Suitable specifically for Autodesk Fusion 360 users, it allows you to import the models directly into this popular design application.

ABOUT ASME B16.5 SLIP-ON FLANGES:

In the realm of piping systems, flanges play a pivotal role, and one particular type that finds widespread use is the ASME B16.5 Slip-On Flange. Conforming to the standards set by the American Society of Mechanical Engineers (ASME) B16.5, this type of flange is favored for its specific design and associated benefits.

What is an ASME B16.5 Slip-On Flange?

The ASME B16.5 Slip-On Flange is characterized by a circular design with a slightly larger diameter than the pipe it connects to. This flange features a raised face on its surface with bolt holes for easy alignment and attachment. Unlike welding neck flanges, slip-on flanges do not have a neck, simplifying installation and reducing stress points.

Applications of ASME B16.5 Slip-On Flanges:

This type of flange is commonly employed across diverse industries, including chemical processing, oil and gas, water treatment, and more. ASME B16.5 Slip-On Flanges are suitable for applications with moderate pressure and temperature conditions, where the emphasis is on ease of installation and cost-effectiveness.

Advantages of ASME B16.5 Slip-On Flanges:

- Ease of Installation: Slip-On Flanges are straightforward to install, making them a preferred choice for projects where quick and uncomplicated assembly is crucial.

- Cost-Effective: These flanges are generally more economical than other types, contributing to cost savings without compromising functionality.

- Versatility: ASME B16.5 Slip-On Flanges are versatile and adaptable to various pipe sizes and materials, enhancing their applicability in different industrial settings.

- Facilitates Inspection and Maintenance: The absence of a neck simplifies visual inspection and maintenance procedures, ensuring efficiency in upkeep.

- Reduced Stress Points: With no welding neck, there are fewer stress points, potentially minimizing the risk of corrosion and fatigue failure.