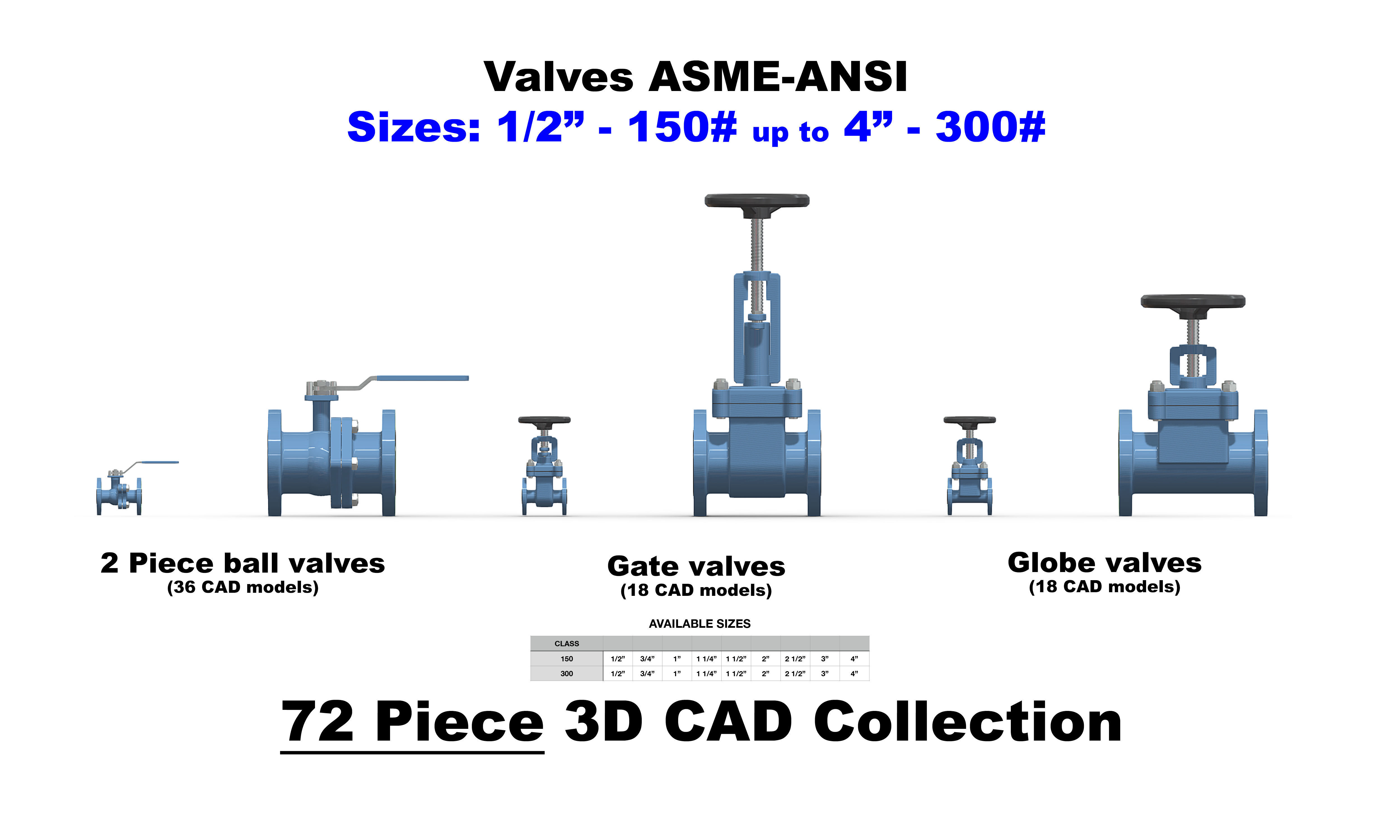

ASME-ANSI Valves Collection - Ball-Gate-Globe valves 3D model

This 3D CAD library contains the 3 most commonly used valves in industrial ASME-ANSI piping systems: ball valves, gate valves and globe valves. These are the valves that you encounter almost everywhere in the oil and gas industry, water treatment plants and process installations.

Sizes:

- 1/2"

- 3/4"

- 1"

- 1 1/4"

- 1 1/2"

- 2"

- 2 1/2"

- 3"

- 4"

Pressure classes:

- 150#

- 300#

Extra: the ball valves are in both an open and a closed position in terms of operating handle.

File types:

- .step (STP): This file type is often used for exchanging 3D models and is compatible with most CAD software, such as SolidWorks, Inventor, AutoCAD, and Fusion 360.

- .f3d (Fusion 360): Suitable specifically for Autodesk Fusion 360 users, it allows you to import the models directly into this popular design application.

KEY VALVES IN PROCESS SYSTEMS:

In the intricate realm of process industries, valves play a pivotal role in managing fluids and gases. Three common valves frequently employed in process systems are ball valves, gate valves, and globe valves. Each valve type possesses unique characteristics and applications, rendering them suitable for specific situations within a process.

1. Ball Valves: Swift and Efficient

Ball valves are renowned for their straightforward construction and rapid operation. These valves utilize a rotating sphere with a bored opening to control the flow of liquids or gases. The primary purpose of a ball valve is to either fully open or fully close the flow. This makes them ideal for applications where swift operation and minimal resistance are crucial. Ball valves are often utilized in water and gas pipelines, where reliability and efficiency are paramount.

2. Gate Valves: Precise Flow Control

Gate valves, also known as slide valves, distinguish themselves through their linear movement of a sliding plate to regulate flow. The primary goal of a gate valve is to enable precise control over the flow of liquids or gases. These valves offer the ability to gradually open or close the passage, making them suitable for situations requiring accurate flow control. Gate valves often find application in industries such as chemistry and oil, where flow control is critical to the production process.

3. Globe Valves: Versatile Applications

Globe valves, characterized by their spherical shape, utilize a movable disk to control flow. The distinctive design of globe valves makes them suitable for various applications, including flow regulation, liquid shutoff, and pressure control. These valves provide a good seal and are effective in managing viscous fluids. Globe valves are commonly found in systems where precision and flexibility are required, such as in steam pipelines or cooling systems.

Differences in Application and Construction

While these valves serve a similar purpose – controlling flow – they differ in construction and application. Ball valves excel in quick operation, gate valves offer precise regulation, and globe valves are versatile. Understanding these differences is essential for selecting the right valve for a specific application, considering factors such as pressure, temperature, and the type of medium being transported.