1/8

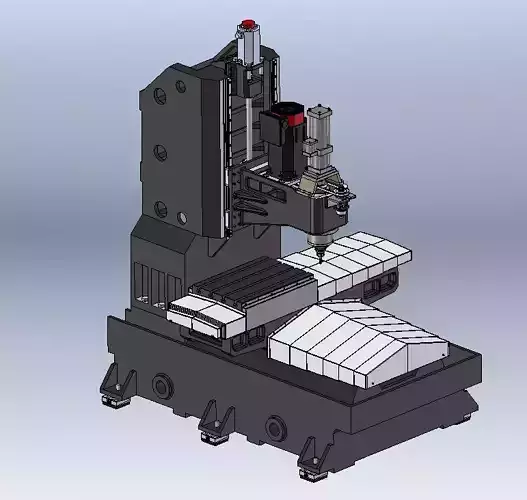

A vertical milling machine is a common metalworking machine used for milling and cutting operations on workpieces. It operates by placing a rotating cutter (end mill) above the workpiece and applying downward pressure in a vertical direction to cut and shape the desired features.

A vertical milling machine typically features a vertical spindle mounted on the top of the machine, capable of moving up and down. The workpiece is placed on a worktable that can move horizontally to facilitate milling operations at different positions.

Vertical milling machines can be used to process various types of metal materials such as steel, aluminum, copper, etc. They are suitable for a range of milling operations, including face milling, chamfering, hole drilling, contour milling, and more.

Vertical milling machines find wide application in manufacturing and machining industries, and are used for producing parts, tools, molds, and more. They offer advantages such as ease of operation, stable cutting performance, convenient workpiece clamping, and suitability for processing small to medium-sized workpieces.

In summary, a vertical milling machine is a machine tool used for metalworking, utilizing vertical cutting operations to mill and cut workpieces. It is a common and essential equipment in the manufacturing industry.

REVIEWS & COMMENTS

accuracy, and usability.