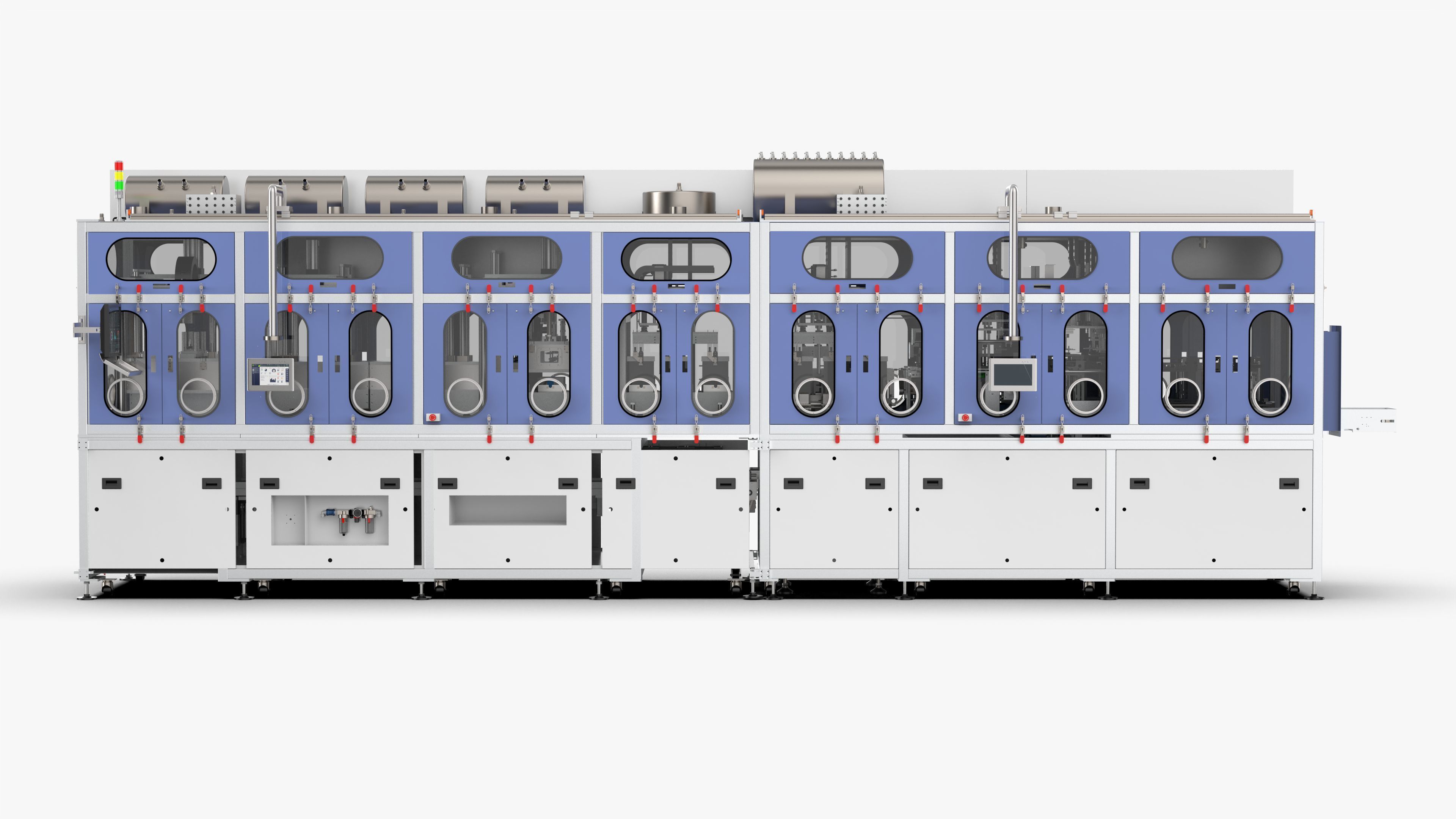

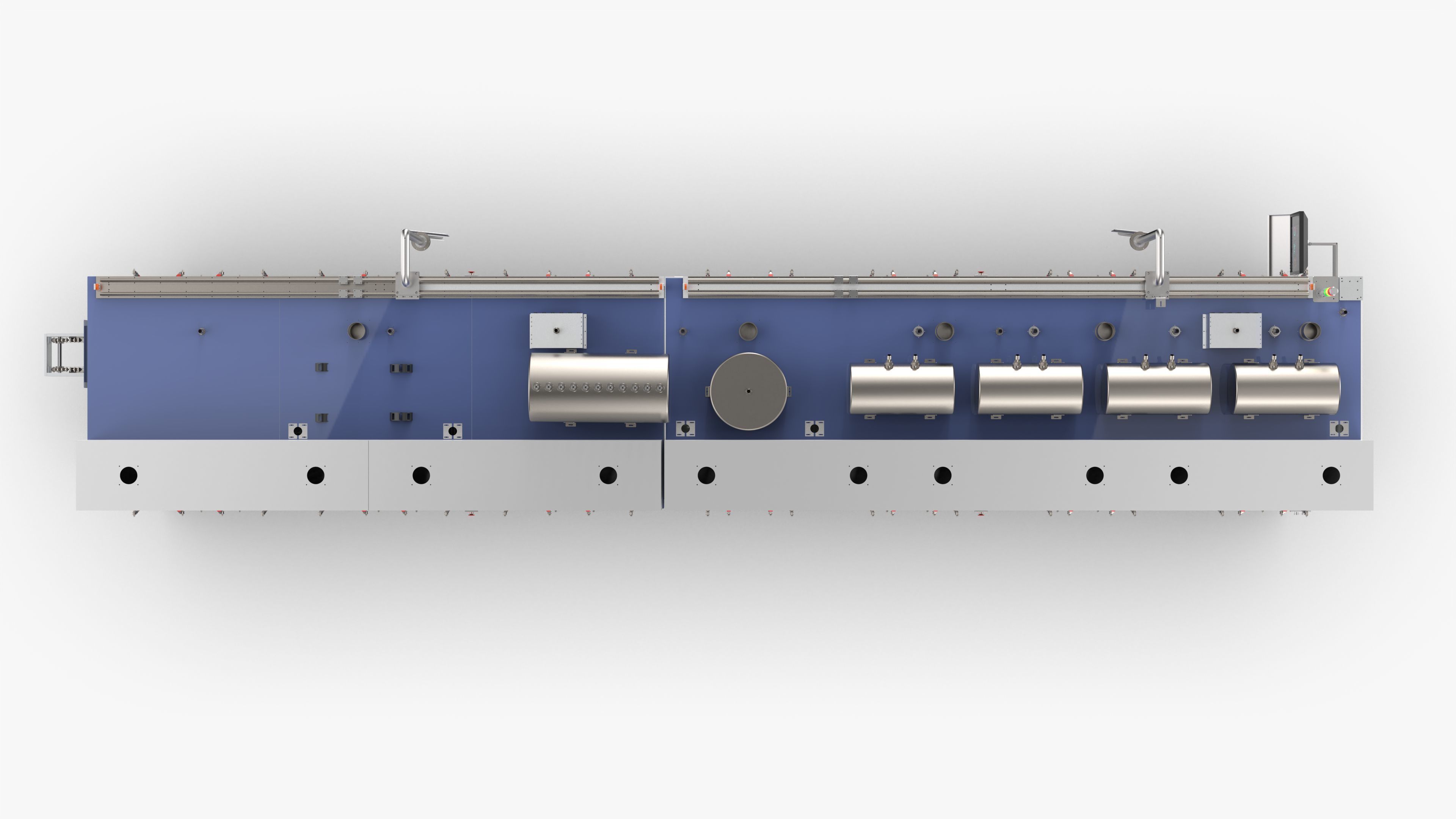

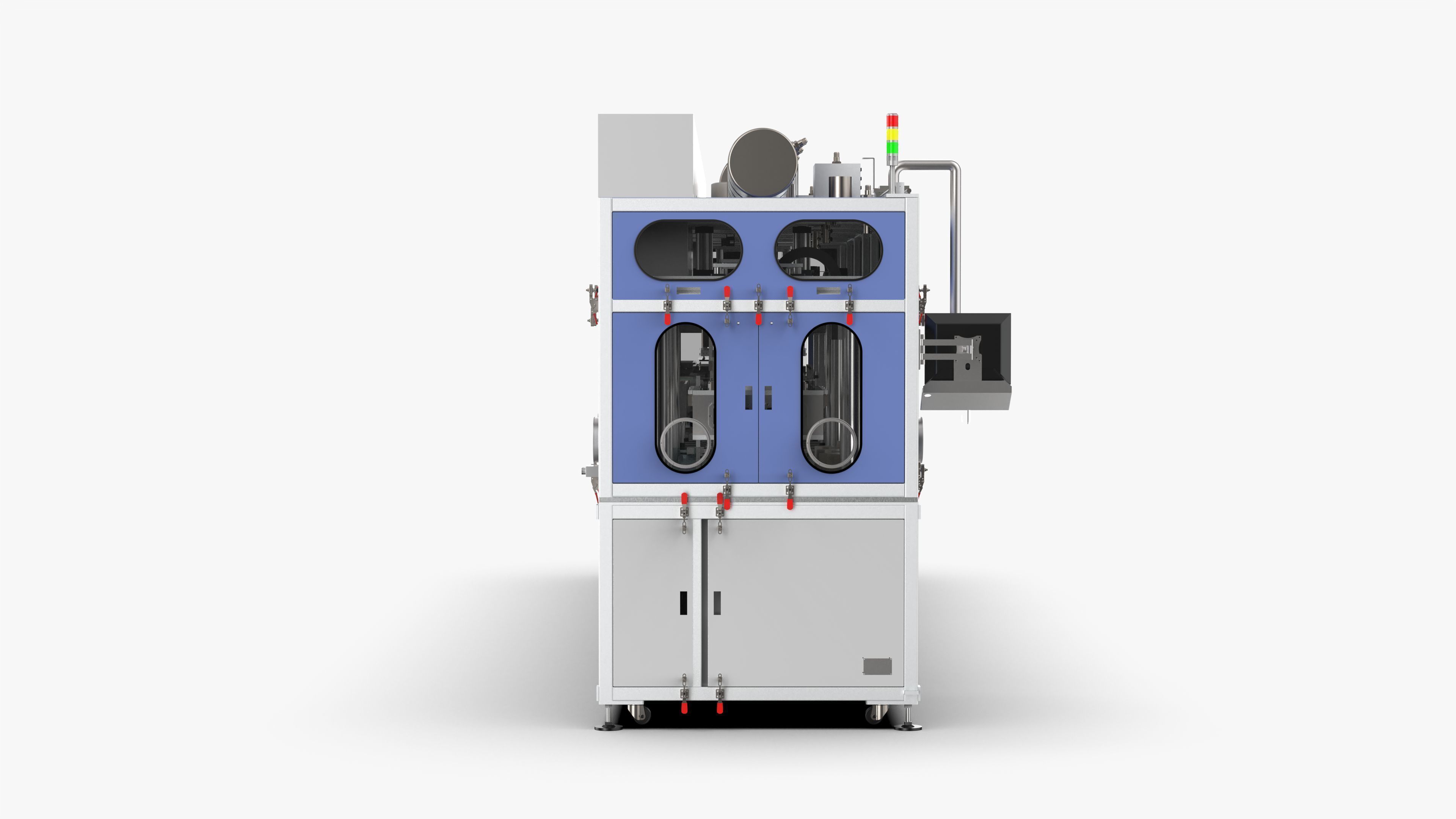

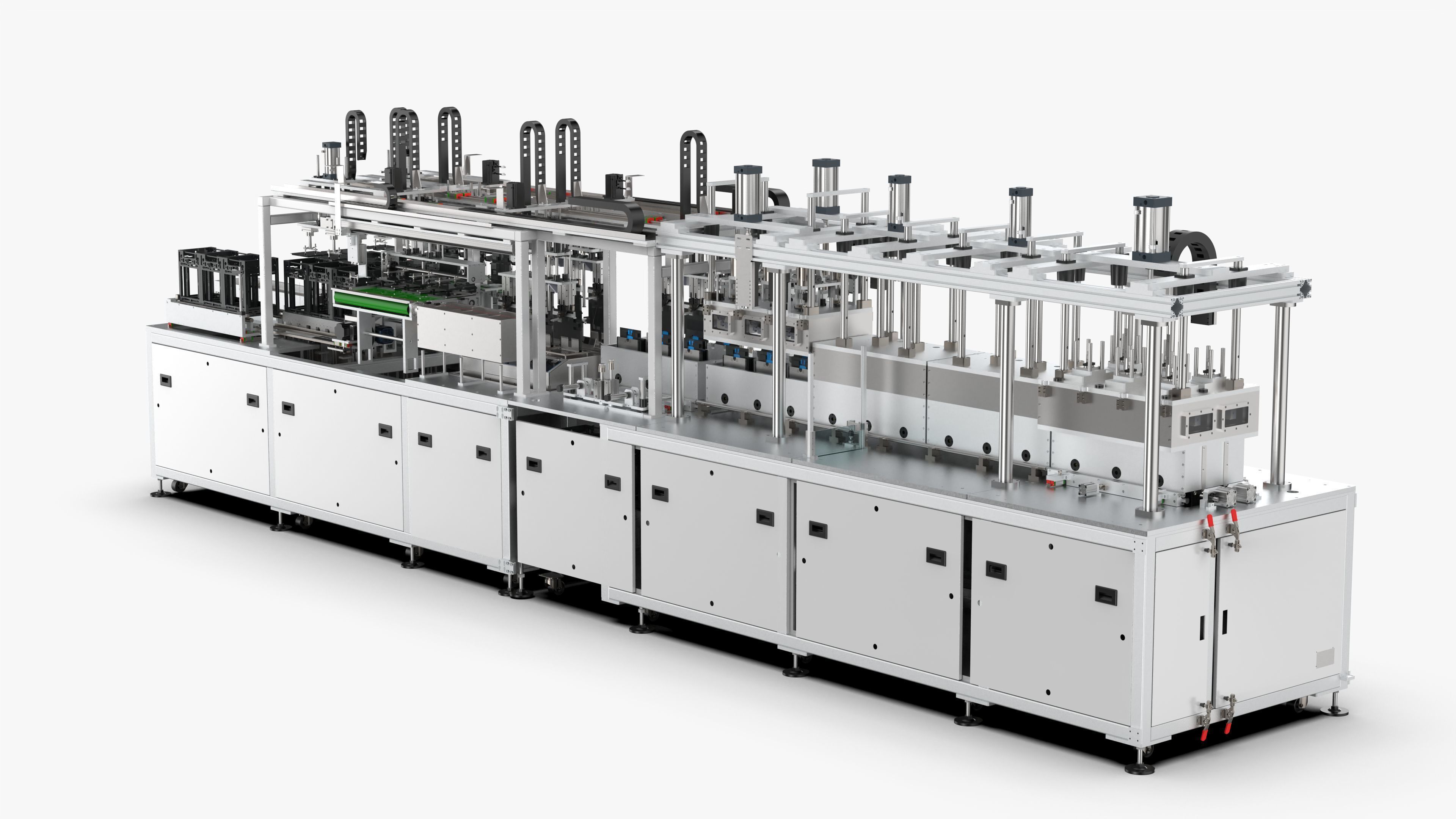

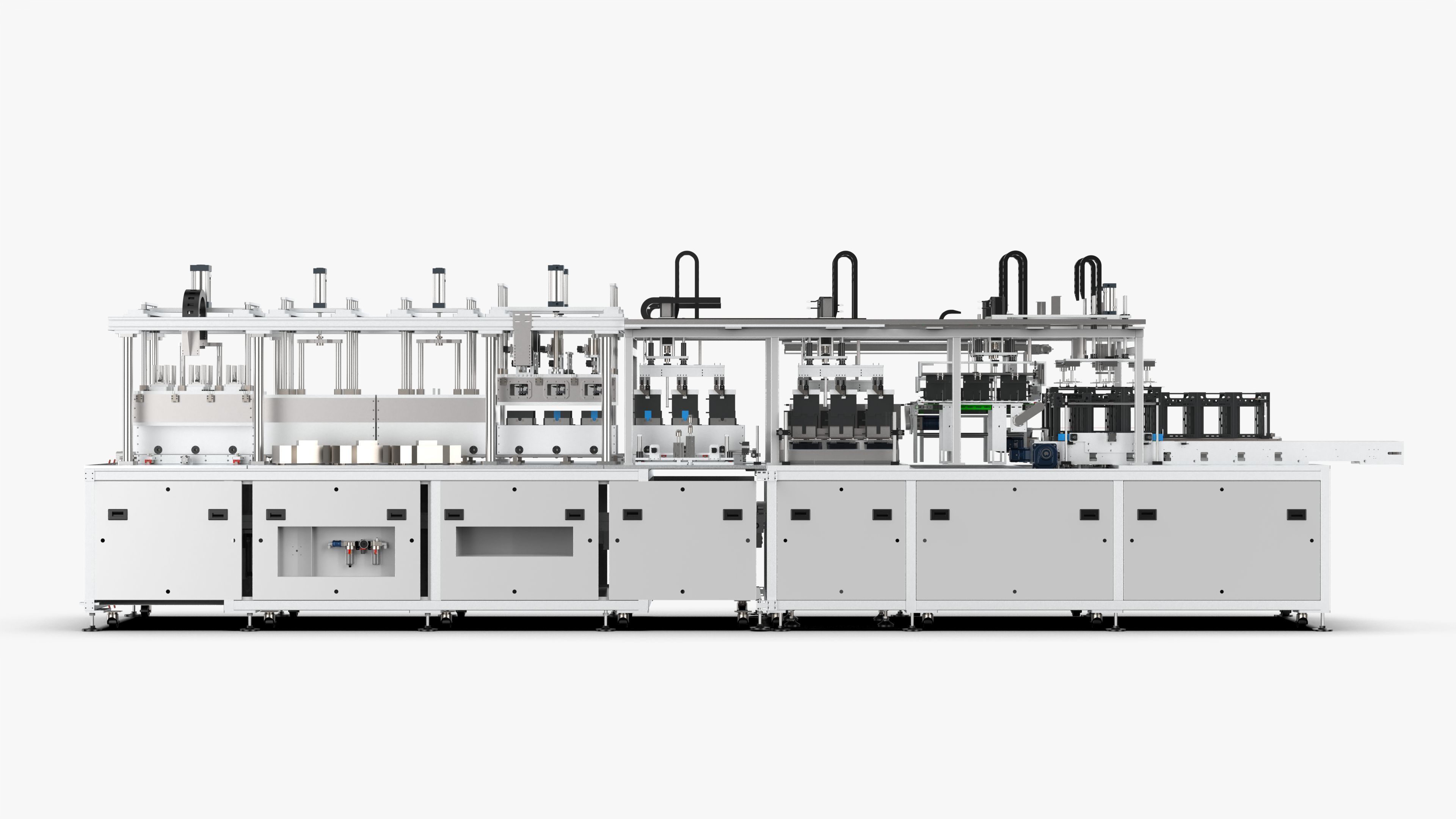

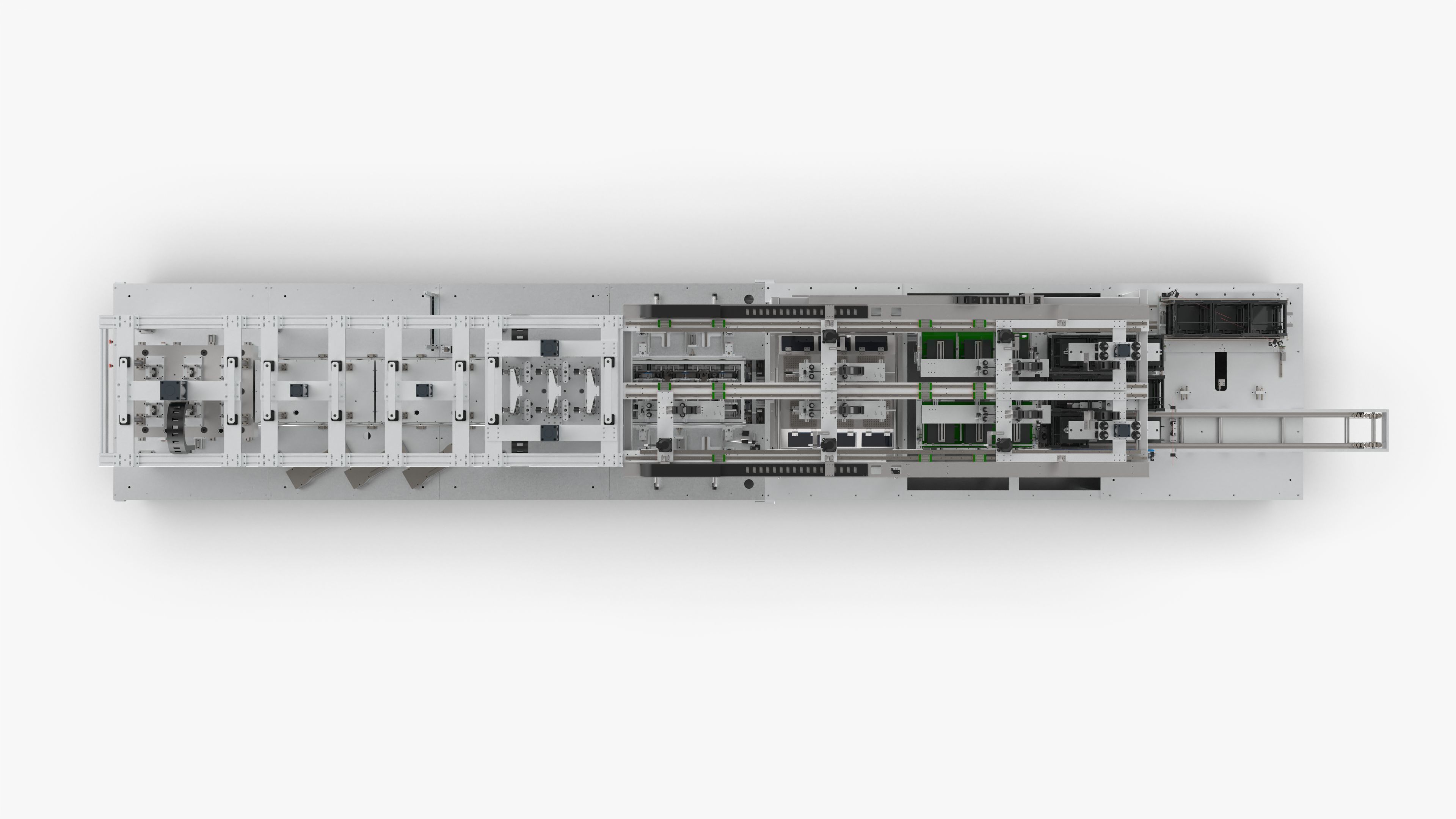

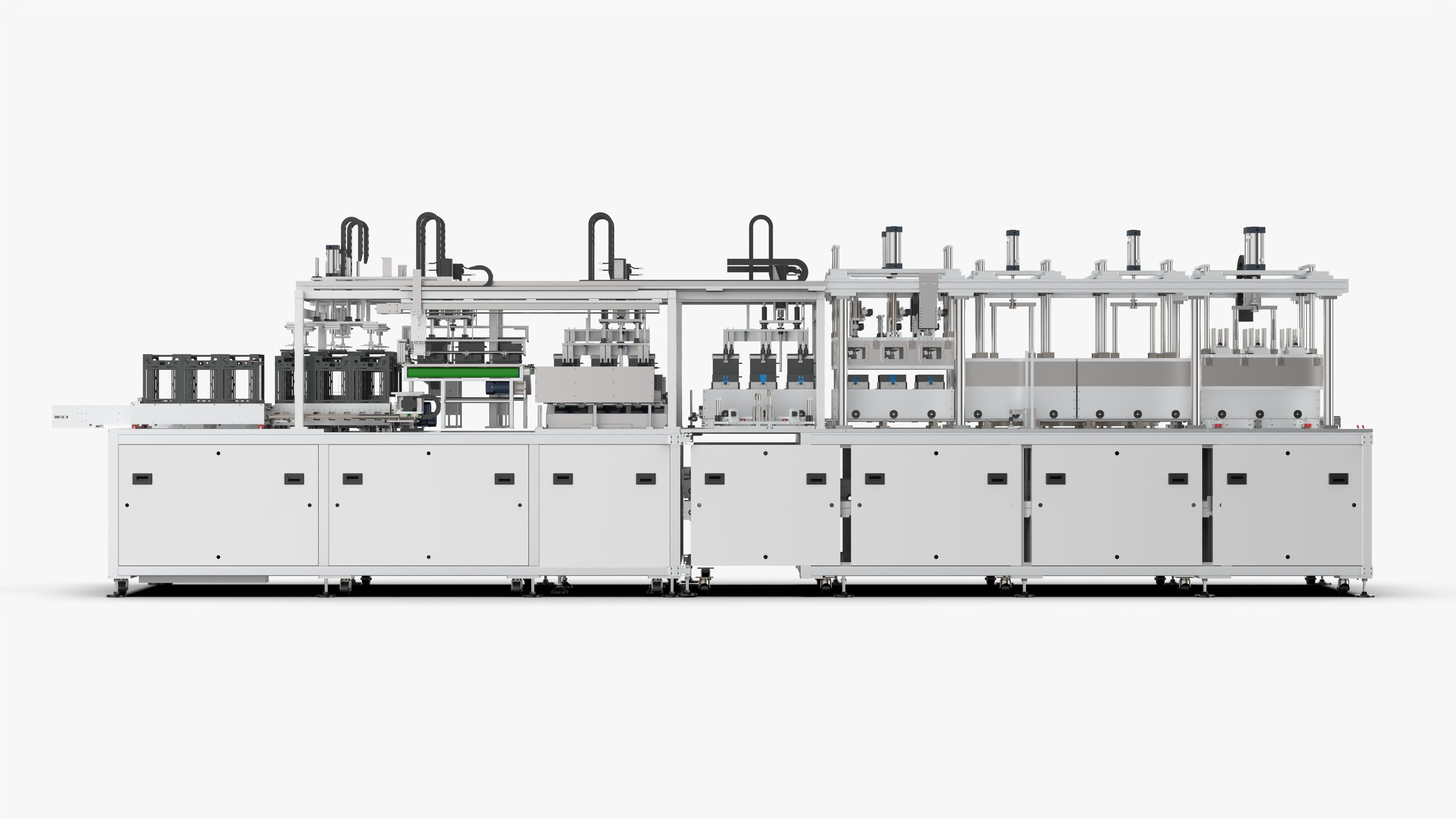

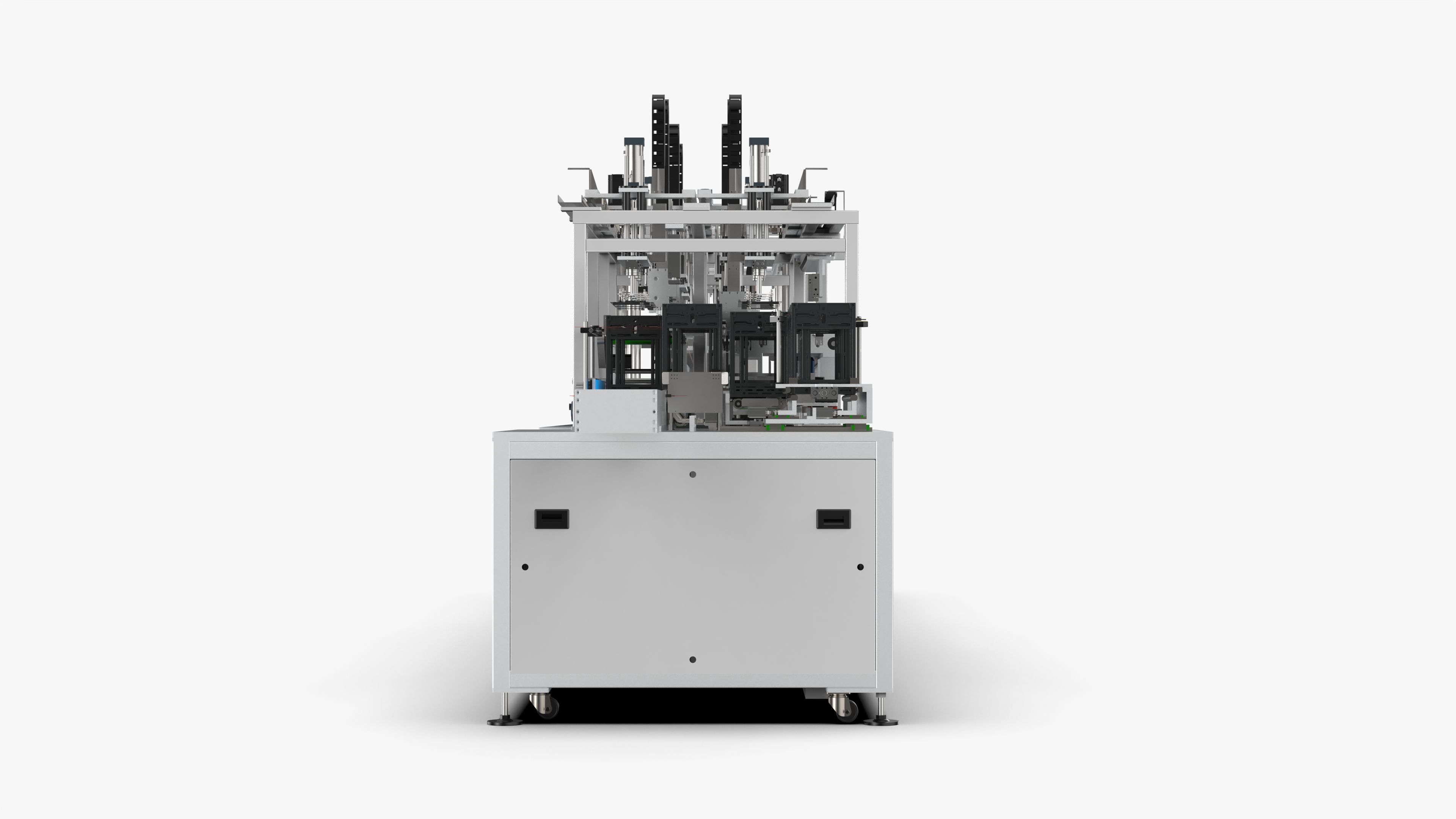

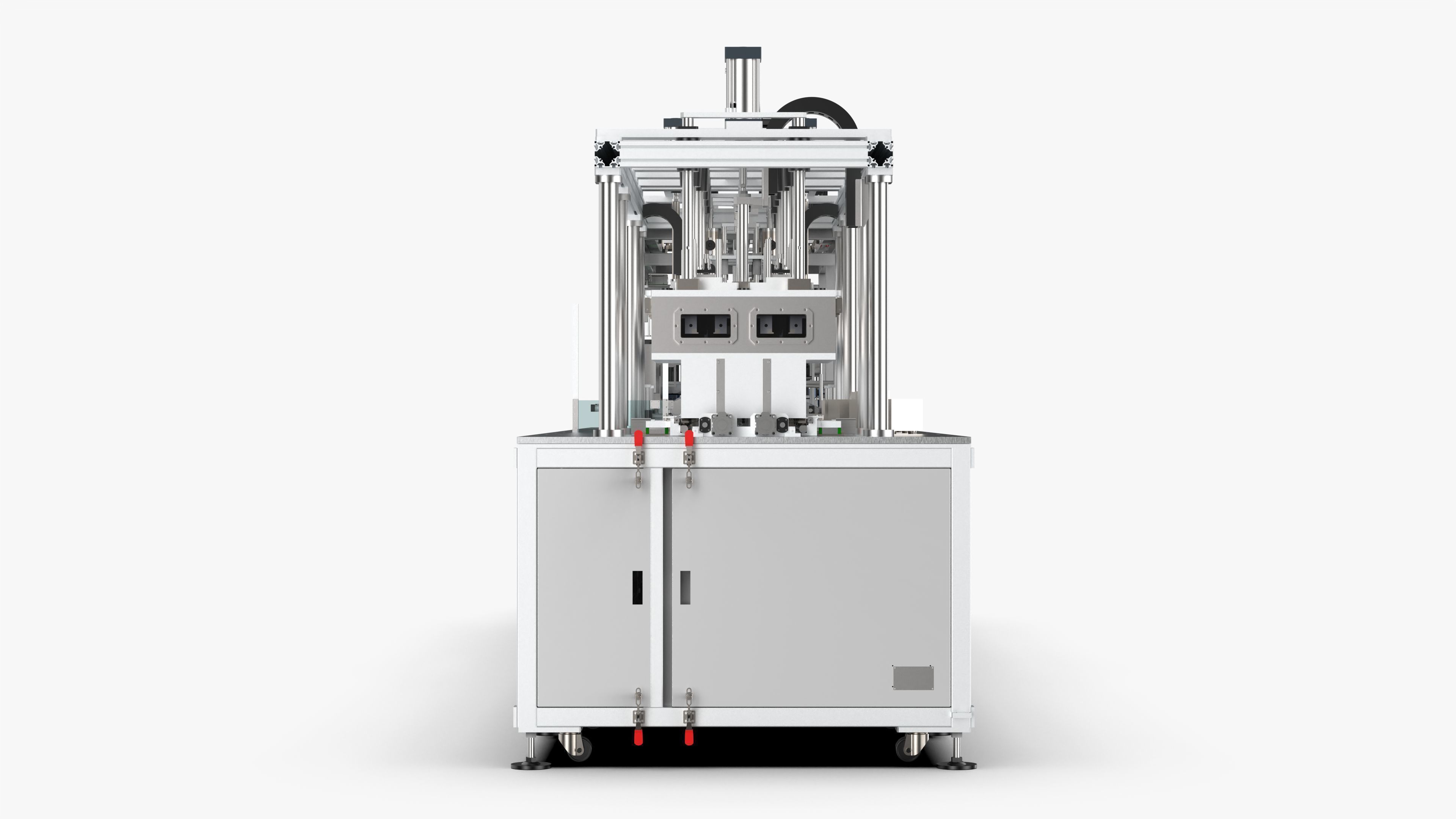

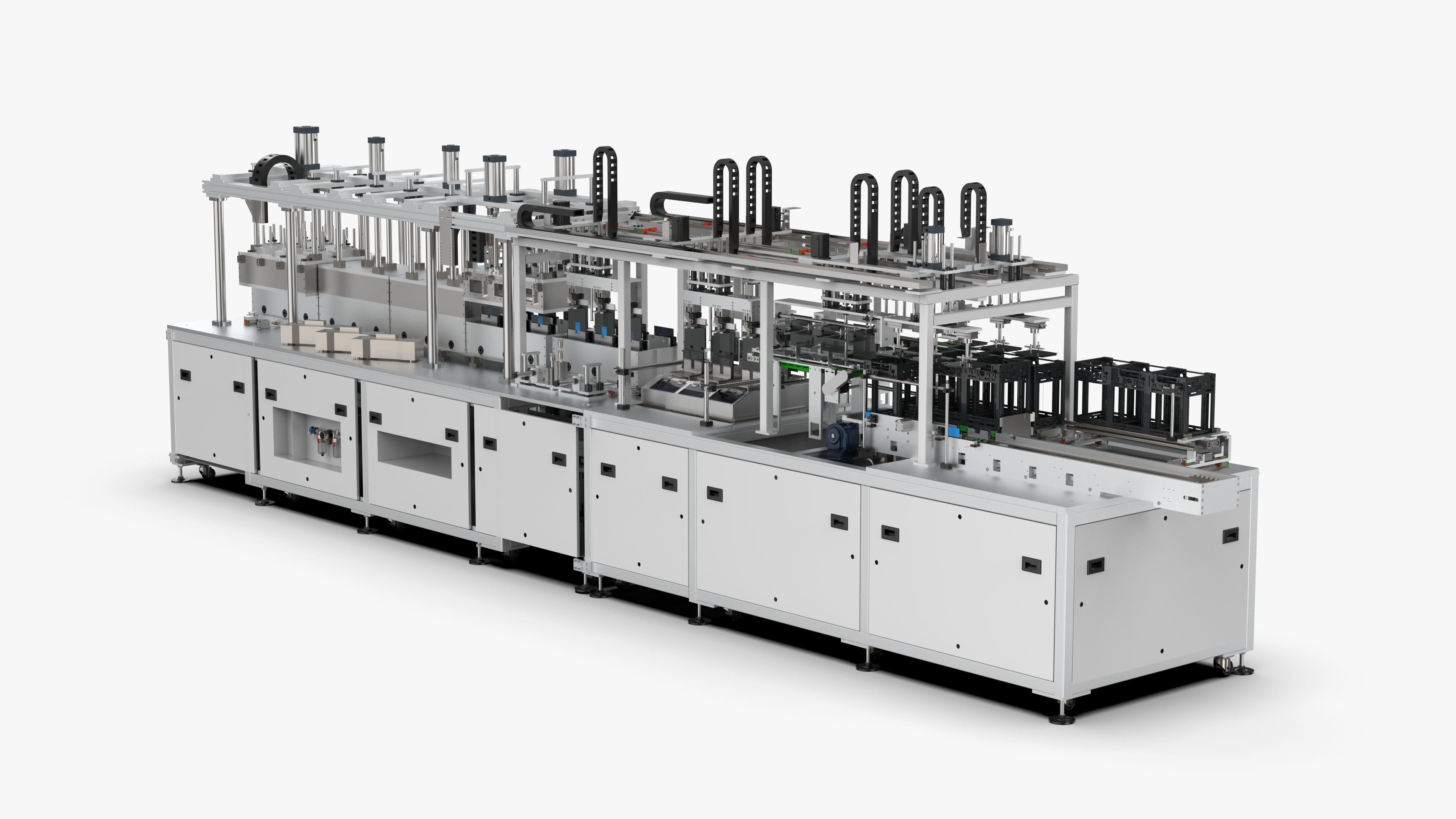

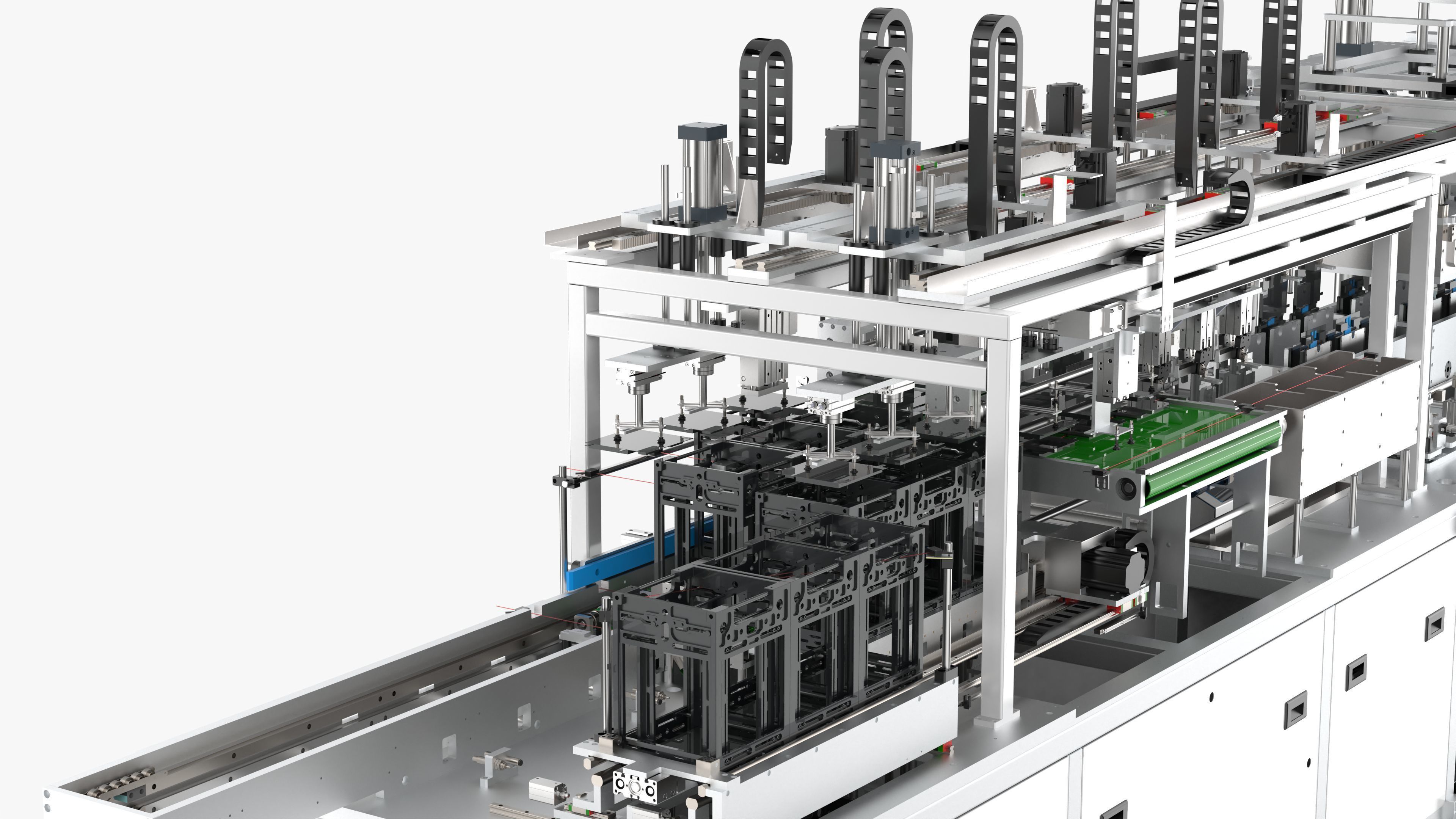

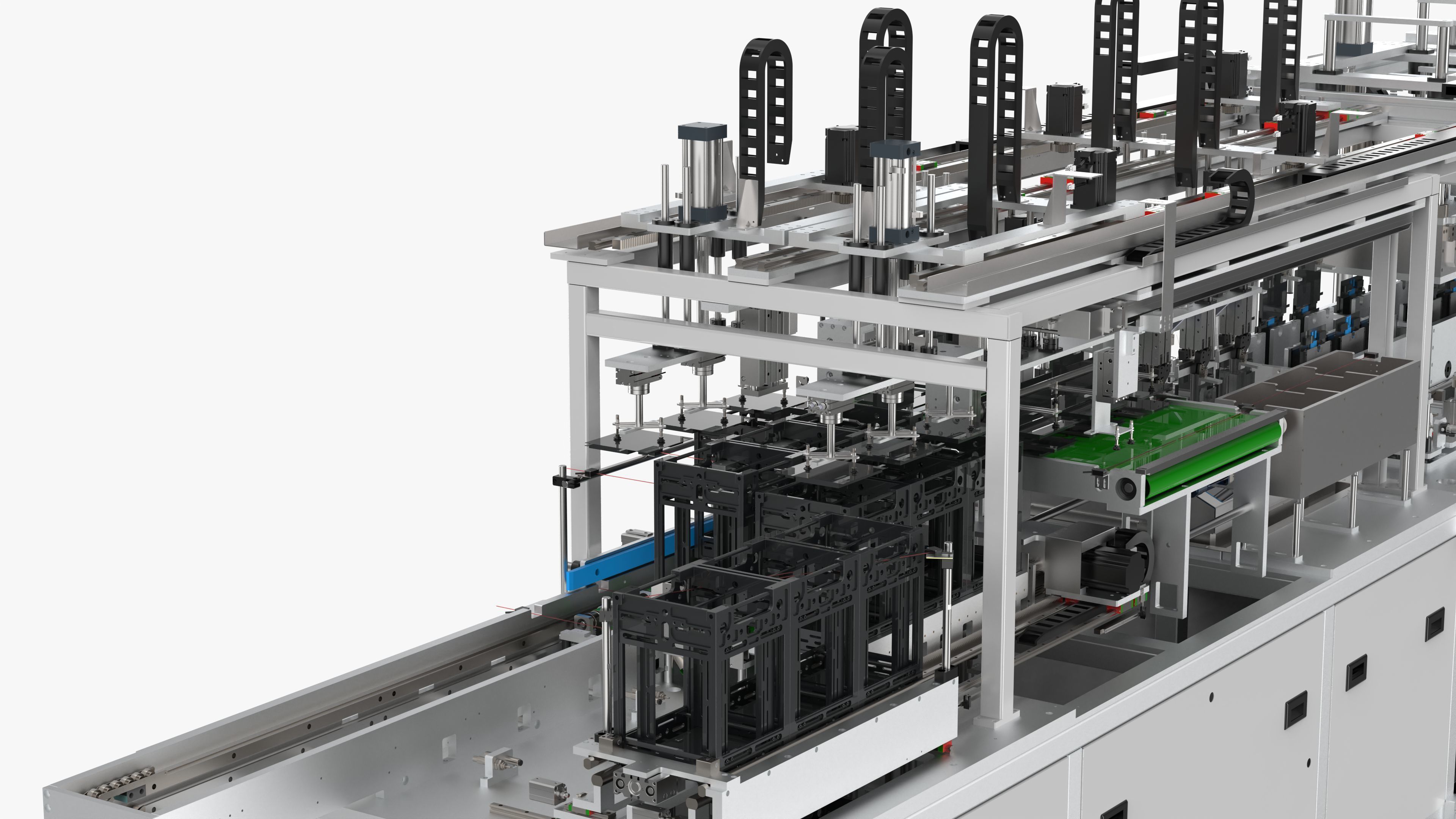

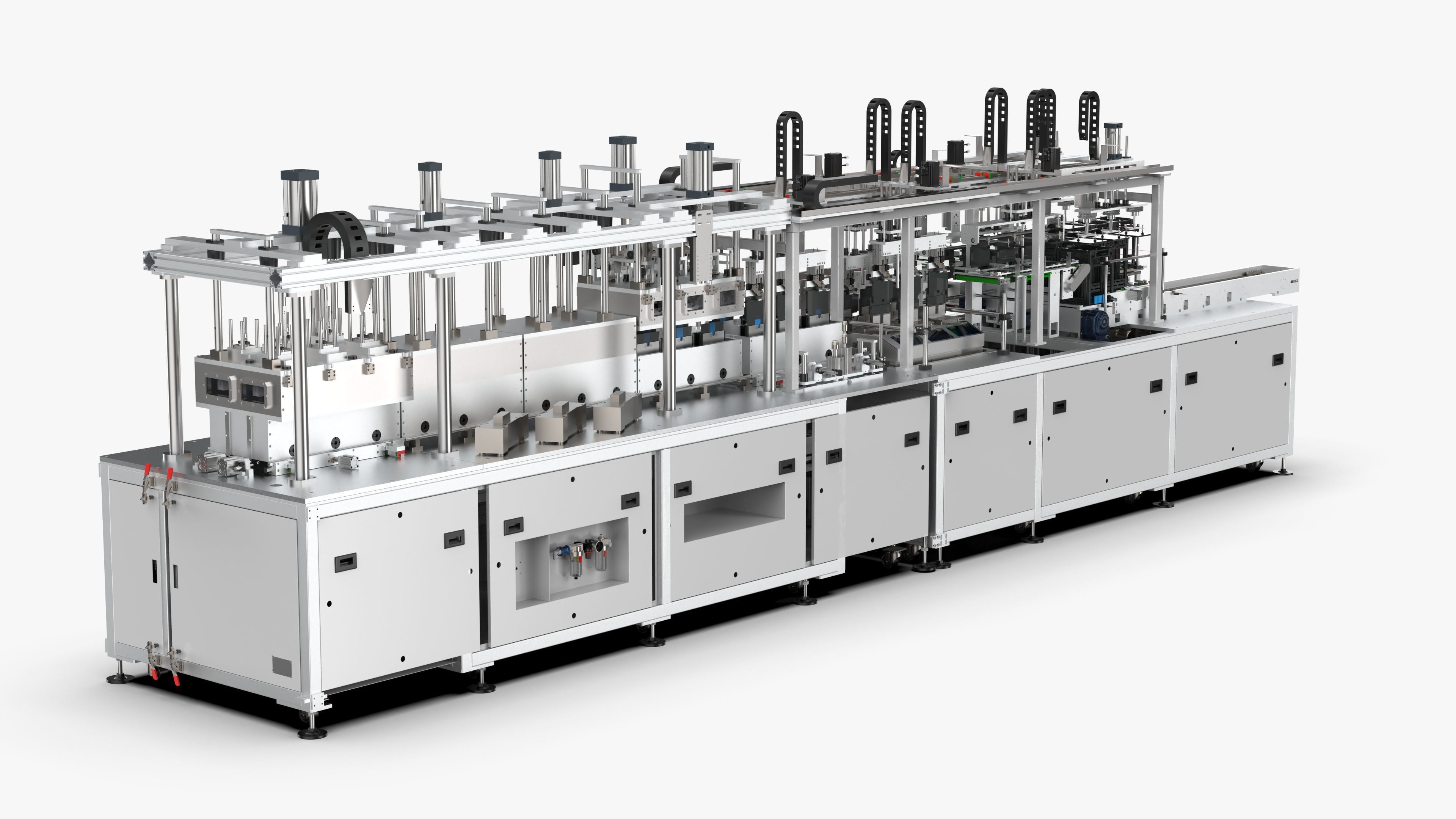

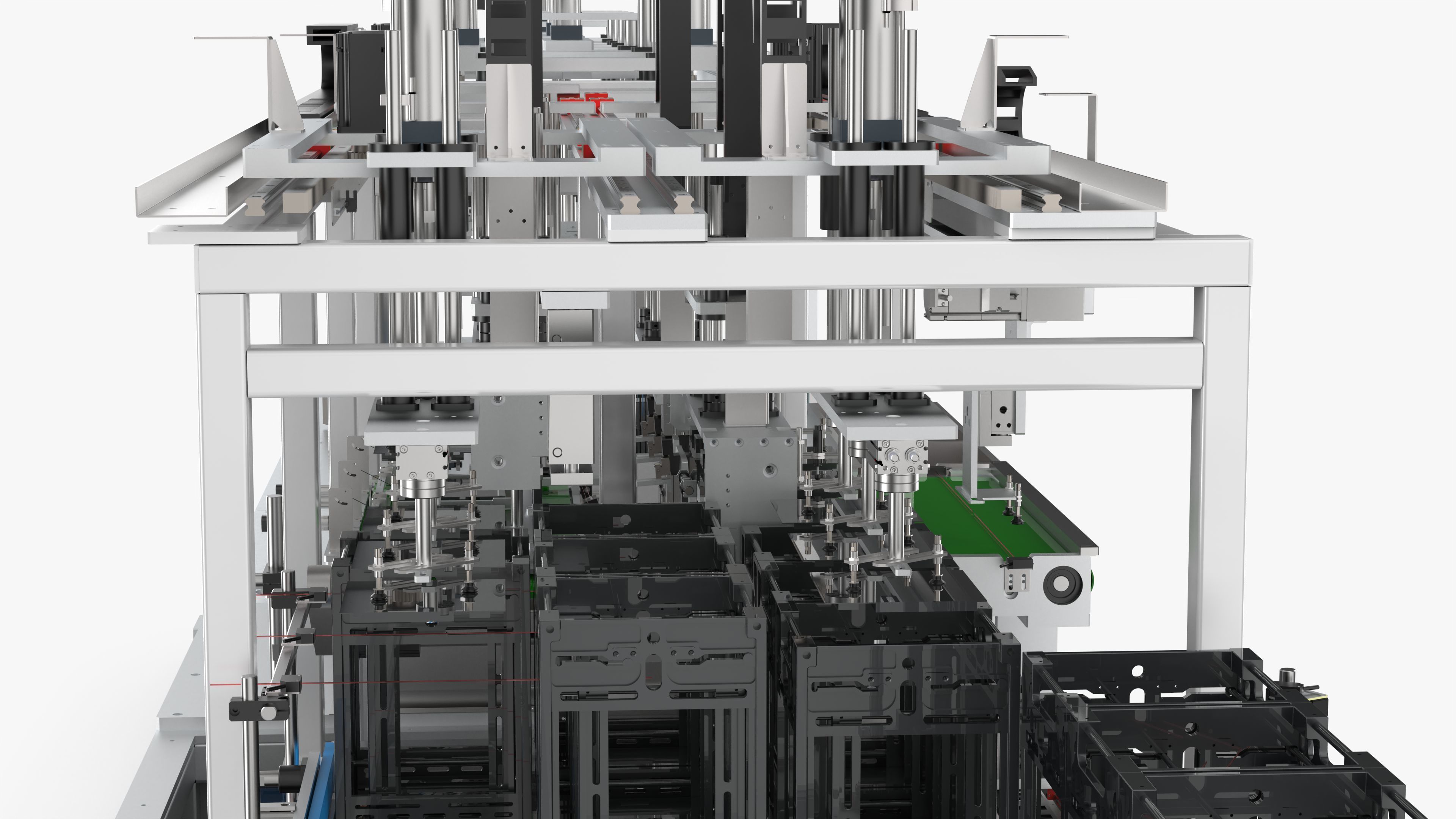

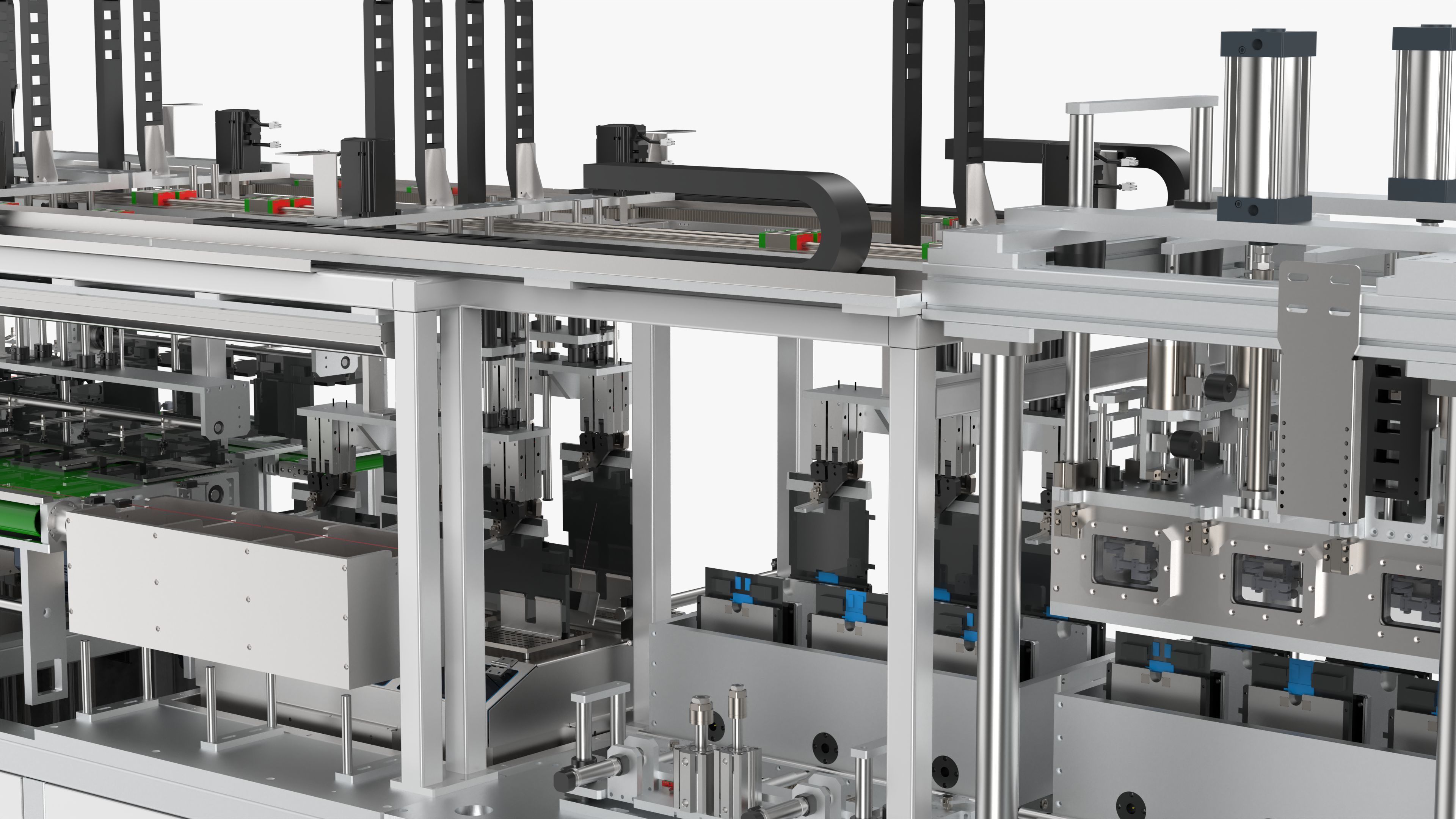

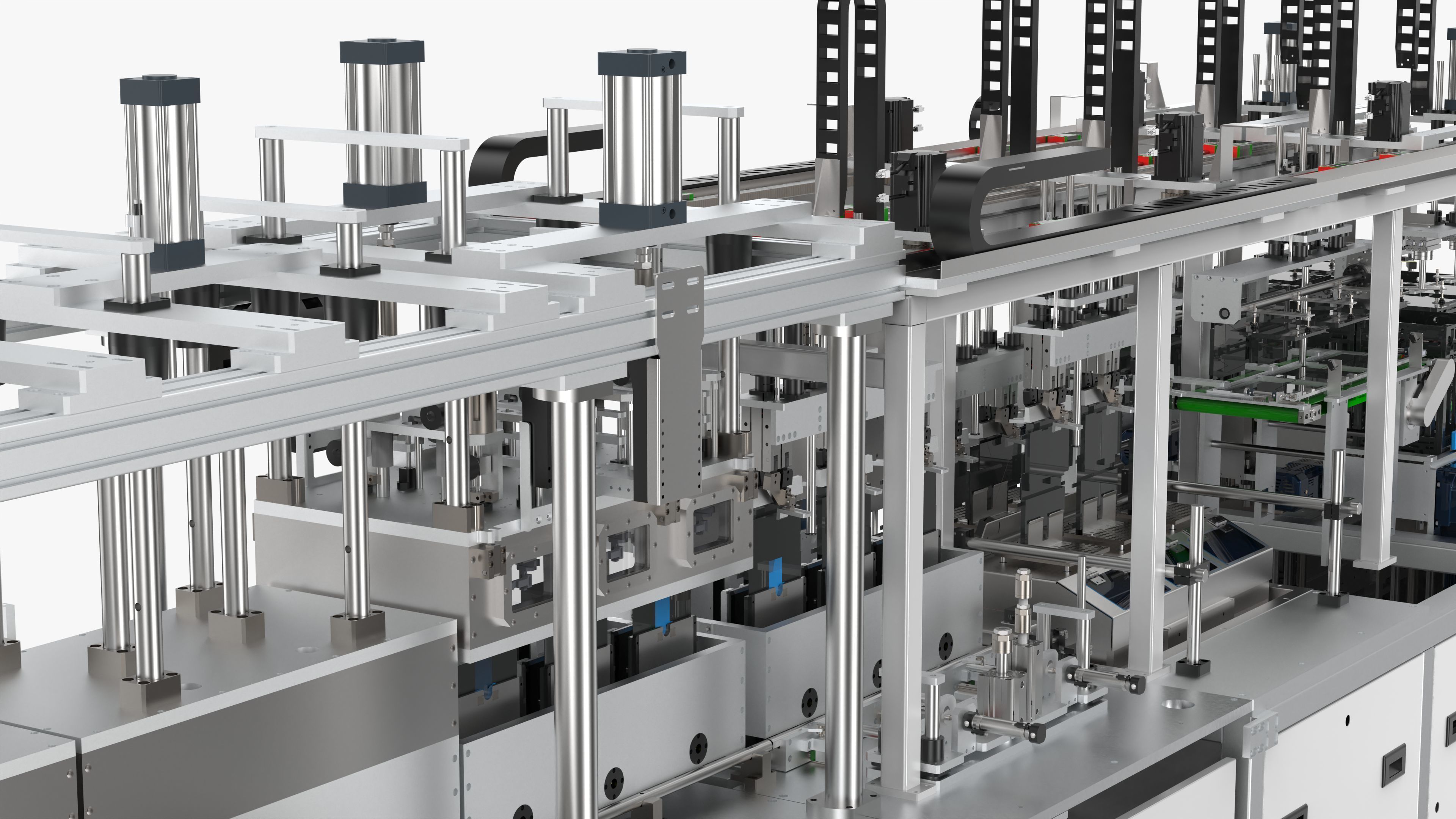

Soft Pack Lithium Battery Vacuum Injection Sealing Machine 3D model

Soft Pack Lithium Battery High-Efficiency Vacuum Injection Sealing Machine

Introduction

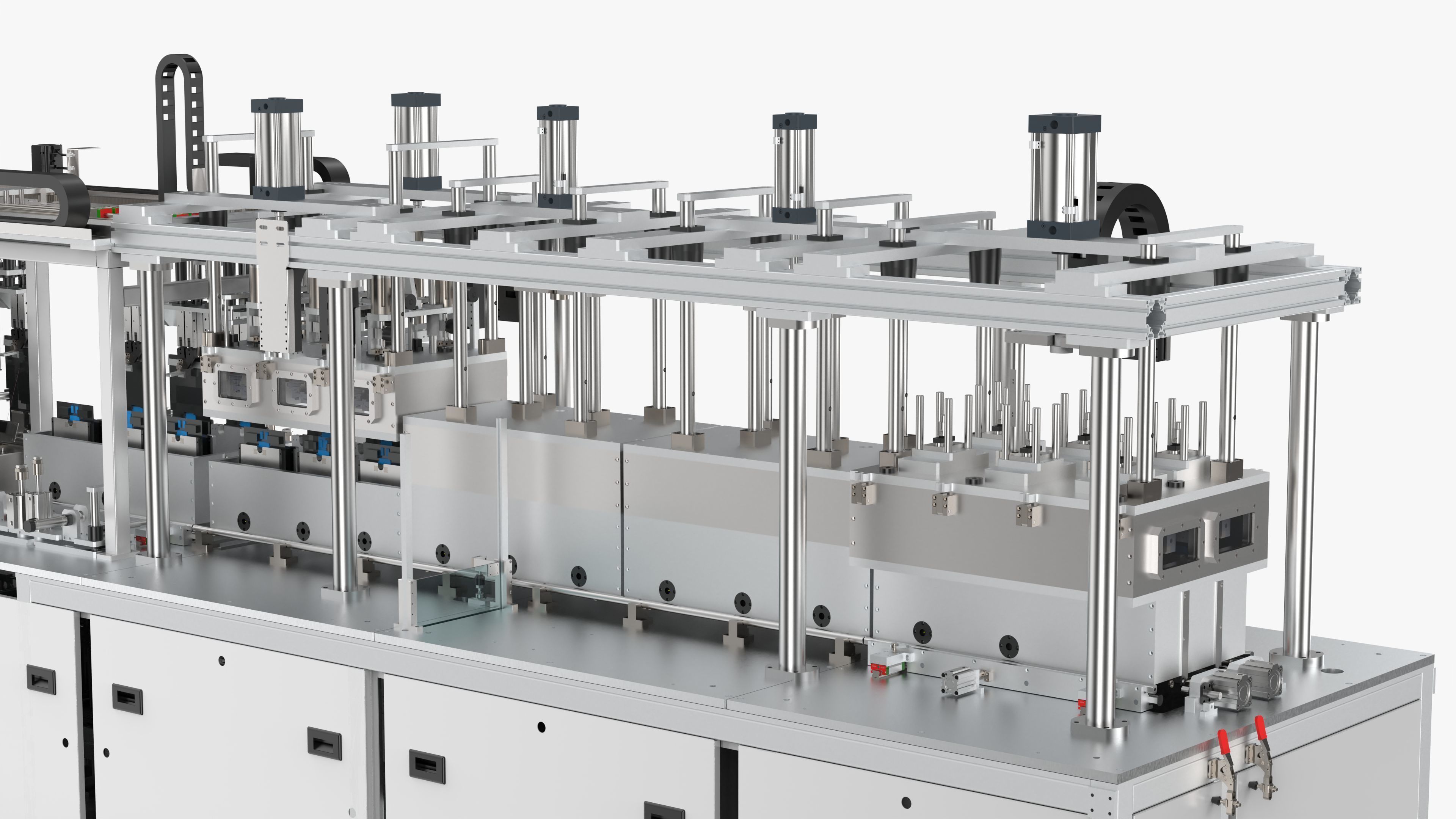

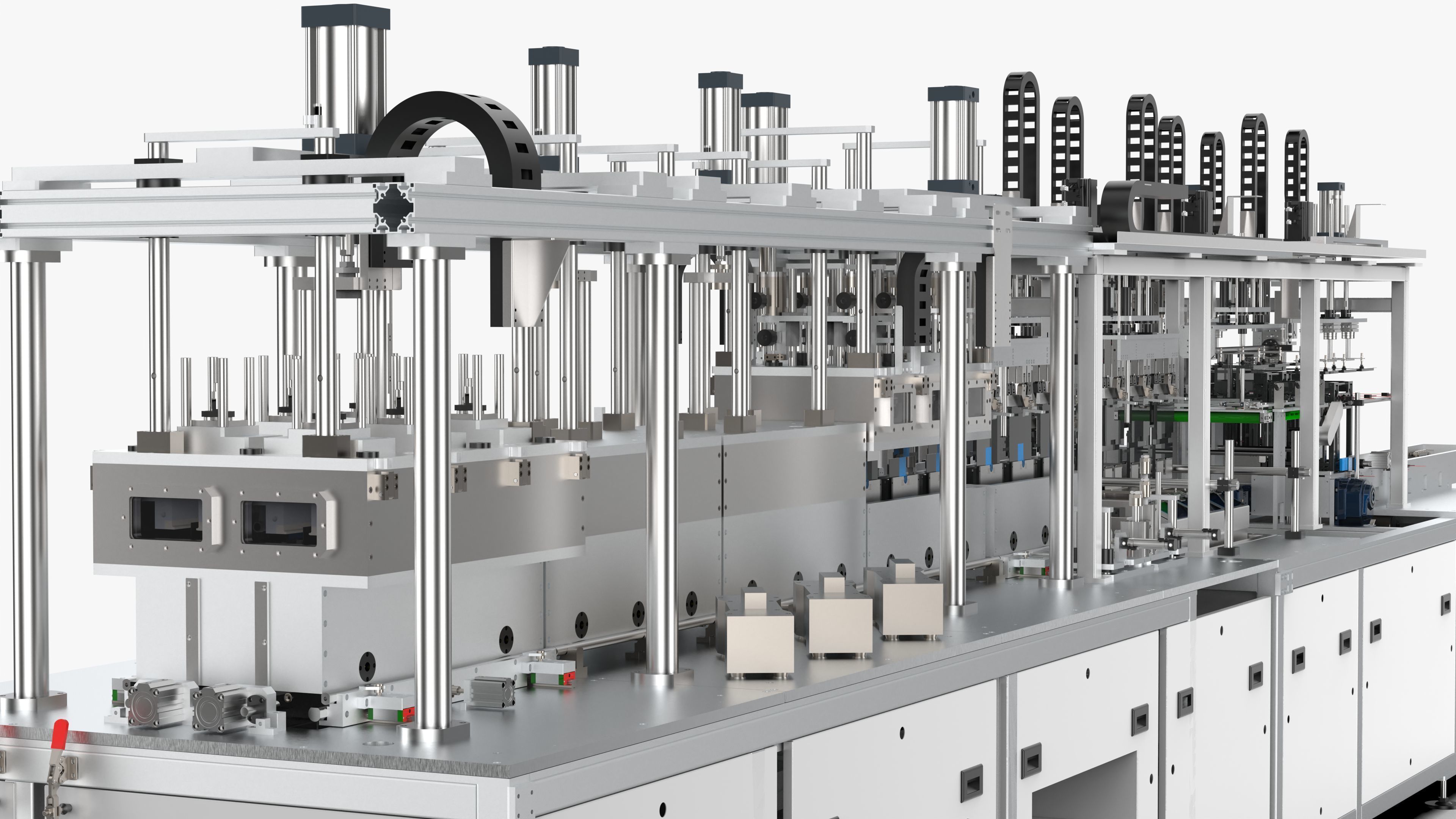

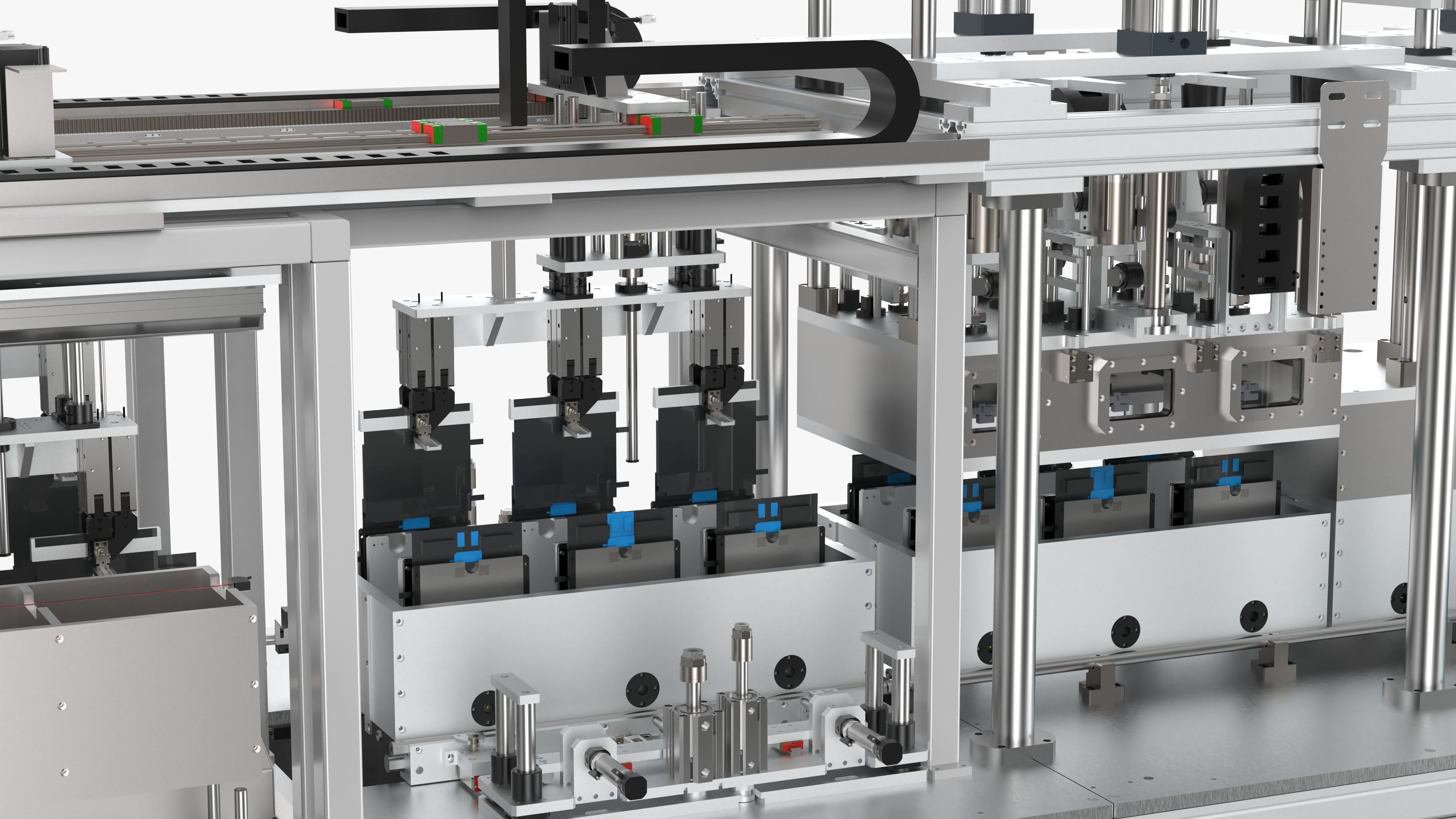

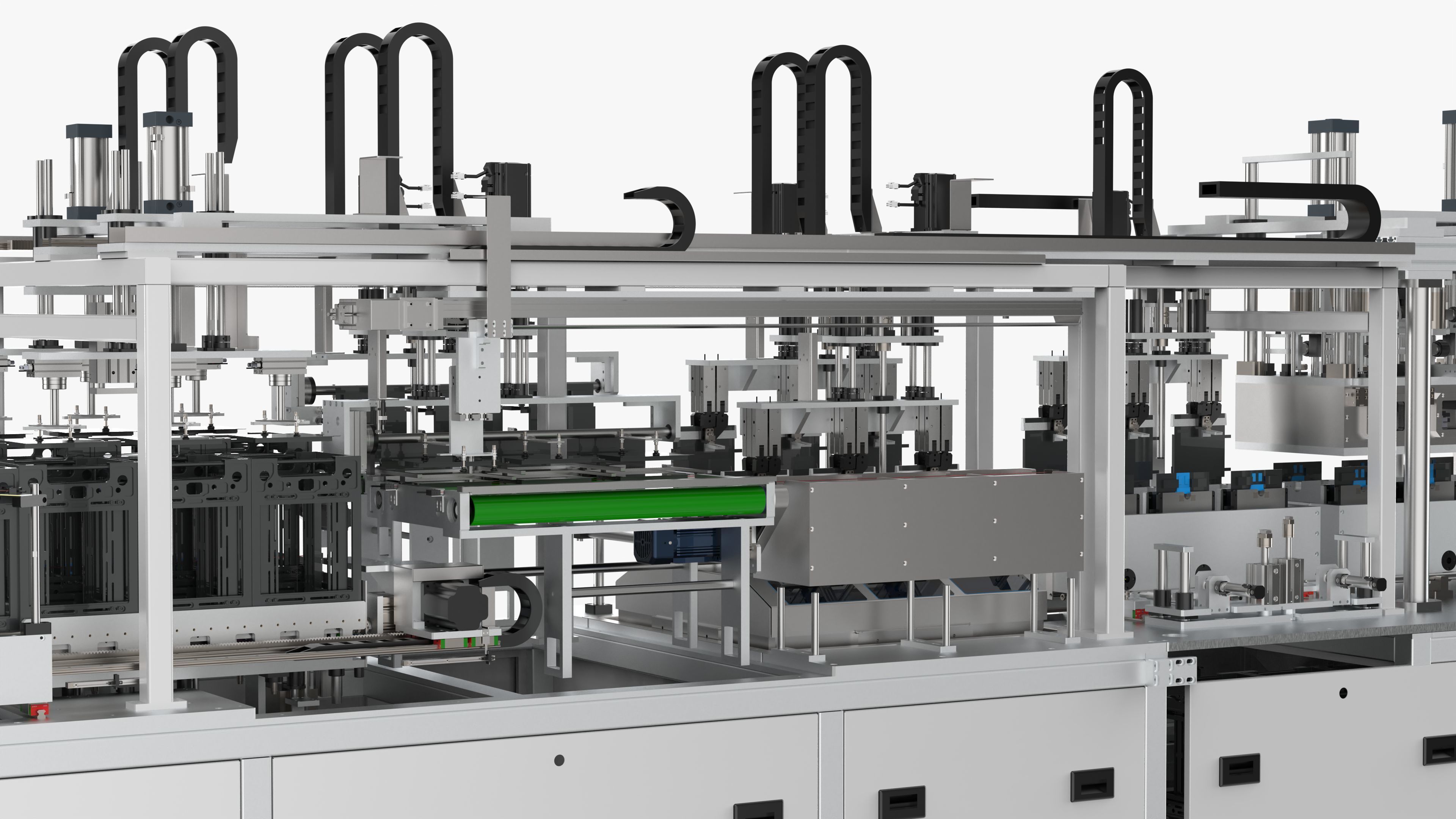

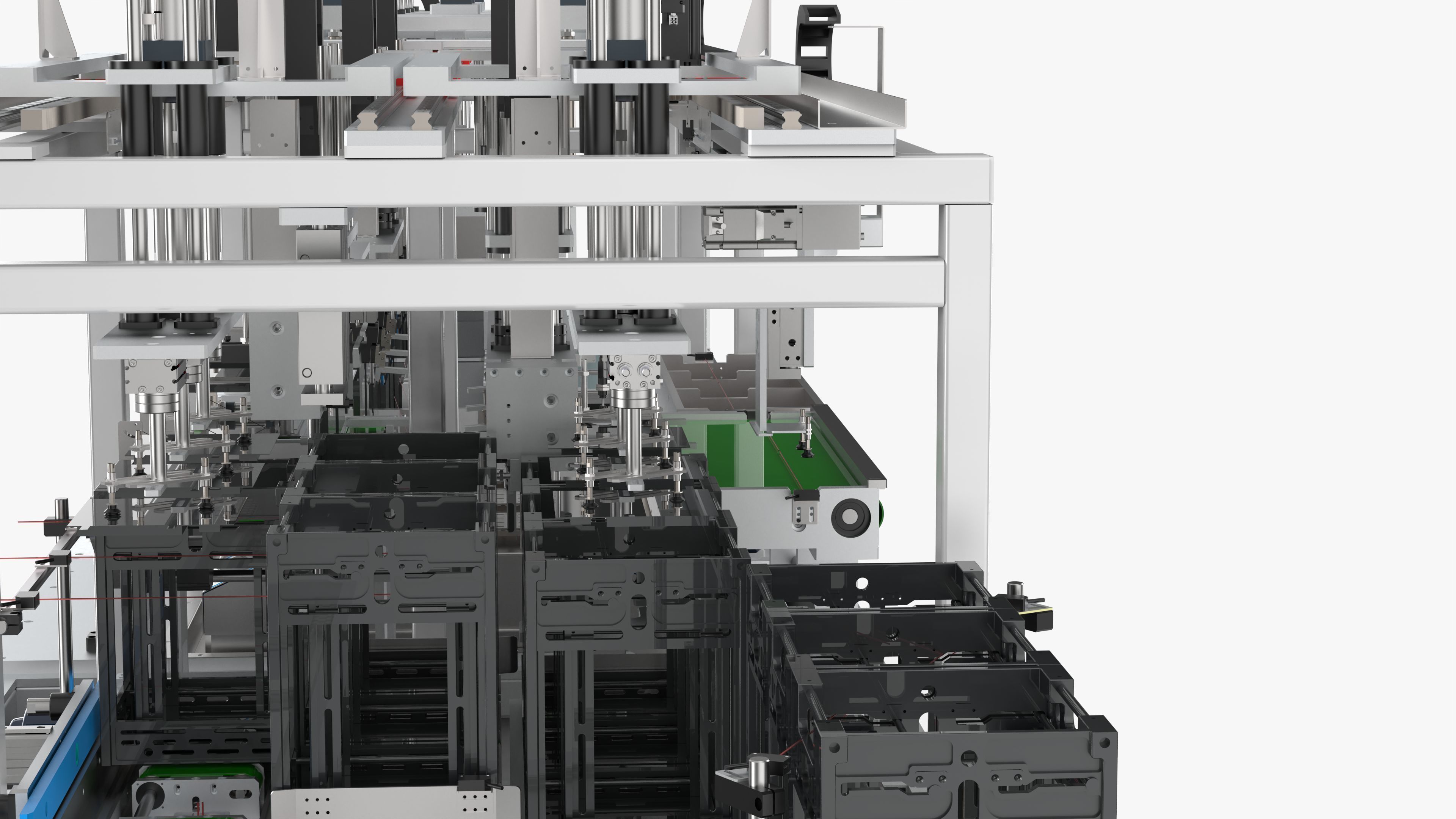

This equipment is mainly used for the automatic liquid injection machine shared by the mobile phone soft pack lithium-ion battery and the power battery. The main process is the automatic feeding and sealing process. Realize the functions of weighing before filling, automatic filling, automatic standing, automatic vacuum sealing, automatic heating and packaging after filling, automatic sorting of defective products, automatic discharge and other functions for soft-packed batteries. The efficiency of the battery vacuum liquid injection machine is relatively high. It is designed according to the structure of one out of six. The cutting and other processes are all automated. Starting from the front-end loading, circulation jig, to the liquid injection station, three-stage static, vacuum packaging, unloading, the structure is complete, the frame is welded with aluminum profiles, and the outer cover can be seen from the figure After hiding, the structure inside is very complicated. The design of the battery grabbing and handling manipulator, and the design of the battery feeding and conveying tooling and fixtures are very valuable to learn. -100kPa high vacuum; Secondly, maintain differential pressure laminar flow injection during liquid injection, avoid spraying and spraying of liquid injection nozzle, and set up multiple vacuum and pressure cycles after liquid injection. In order to prevent excessive volatilization of electrolyte, the evacuation pressure is set at -65~-76kPa; Since the vacuum needs to be drained before liquid injection, and the vacuum needs to be low during the pumping cycle after liquid injection, in order to increase the stability of the equipment, four sets of vacuum systems, three vacuum pumps and four storage tanks are specially added. Air filling. One set of vacuum system consists of one TRP24 vacuum pump for high vacuum pumping; the other set of vacuum system consists of two TRP48 vacuum pumps, and adopts the international advanced vacuum differential pressure liquid injection process to ensure liquid injection accuracy, stable production and battery Full infiltration of electrolyte, taking into account clean production and easy maintenance of equipment.

File Formats

- Keyshot 10

- STEP (Standard for the Exchange of Product Data)

- IGES (Initial Graphics Exchange Specification)

- STL (Standard Tessellation Language )

- OBJ (Object Files)

- x_t (Parasolic Model Part File)

Geometry

- Polygons: 18,493,018

- Vertice: 55,497,054