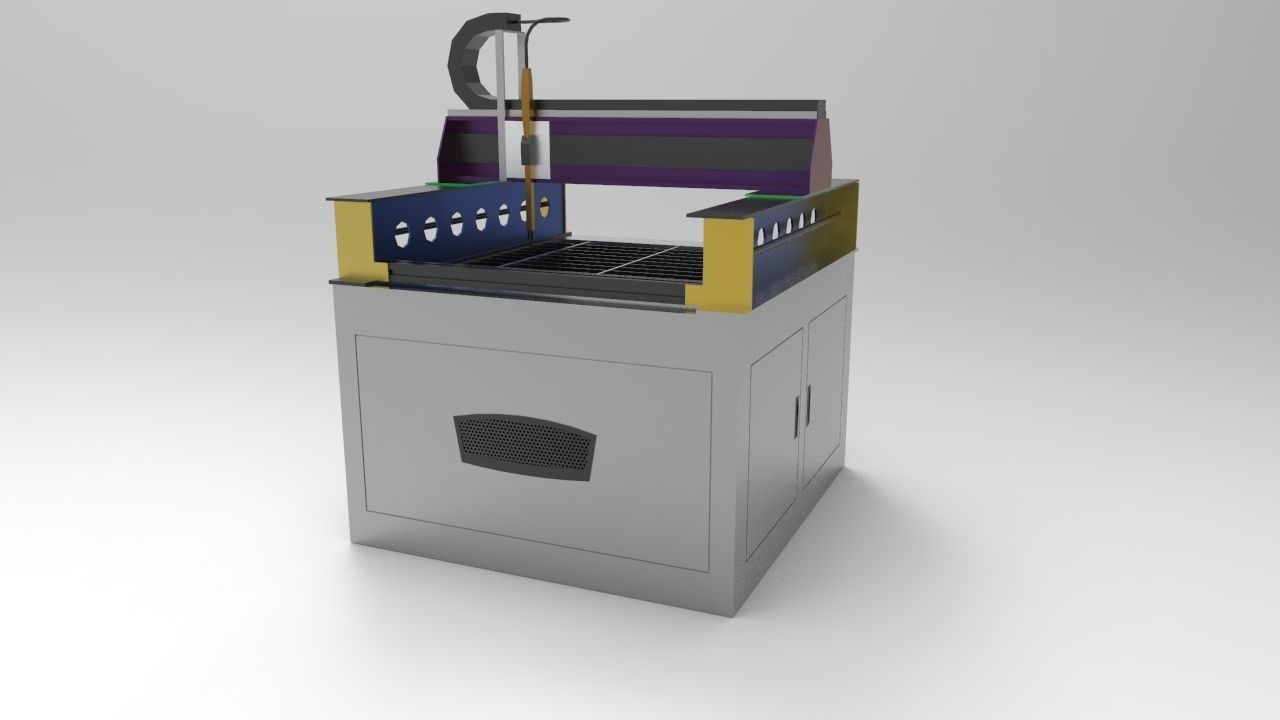

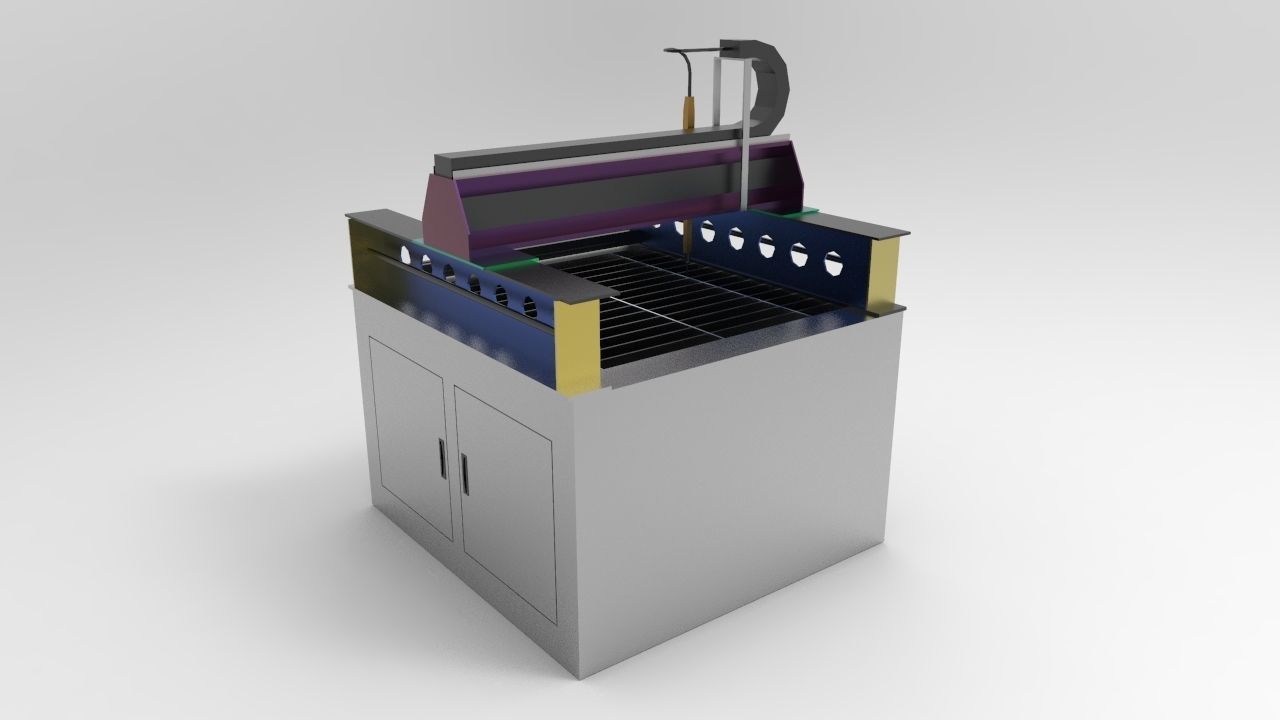

Plasma Cutting Machine 3D model

A Plasma Cutting Machine is a cutting-edge tool that utilizes the power of ionized gas, known as plasma, to cut through electrically conductive materials with remarkable speed and precision. This versatile machine can effortlessly slice through various metals, including steel, aluminum, and stainless steel, making it a staple in industries like metal fabrication, automotive, and construction. The process involves directing a high-velocity jet of ionized gas at the material, which rapidly heats and melts the metal, while an additional flow of gas blows away the molten metal, creating a clean and smooth cut. Plasma cutting machines excel in handling thick materials and intricate designs, providing manufacturers with greater flexibility and efficiency in their production processes. Moreover, the introduction of computer numerical control (CNC) technology has further enhanced the capabilities of plasma cutting machines, enabling automated and highly precise cutting operations. As a result, plasma cutting machines have become a key tool in modern manufacturing, allowing businesses to achieve faster production rates, minimize material wastage, and produce high-quality parts and components.