1/5

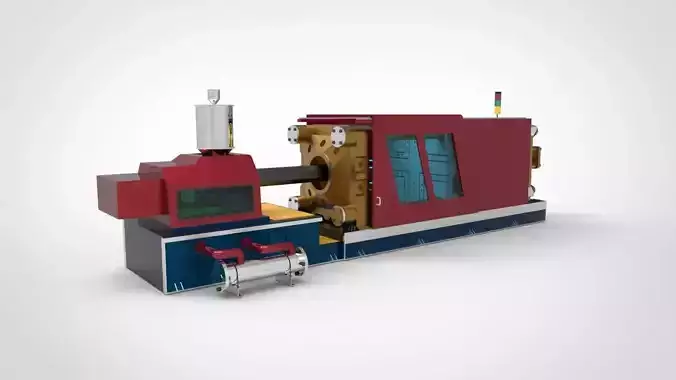

An Injection Molding Machine stands as a cornerstone in modern manufacturing, representing a robust and efficient method for mass-producing a wide range of plastic products and components. This ingenious technology involves injecting molten plastic into a carefully crafted mold under high pressure, allowing it to take the desired shape with remarkable precision and consistency. The versatility of Injection Molding Machines enables the production of everything from simple household items to intricate automotive parts, all while maintaining strict adherence to design specifications. This process offers several advantages, including reduced material wastage, shortened production cycles, and the ability to create complex geometries that would be otherwise challenging using conventional methods. With its cost-effectiveness and capacity to meet high-volume demands, the Injection Molding Machine remains a critical asset in various industries, contributing significantly to the advancement of modern manufacturing techniques.

REVIEWS & COMMENTS

accuracy, and usability.