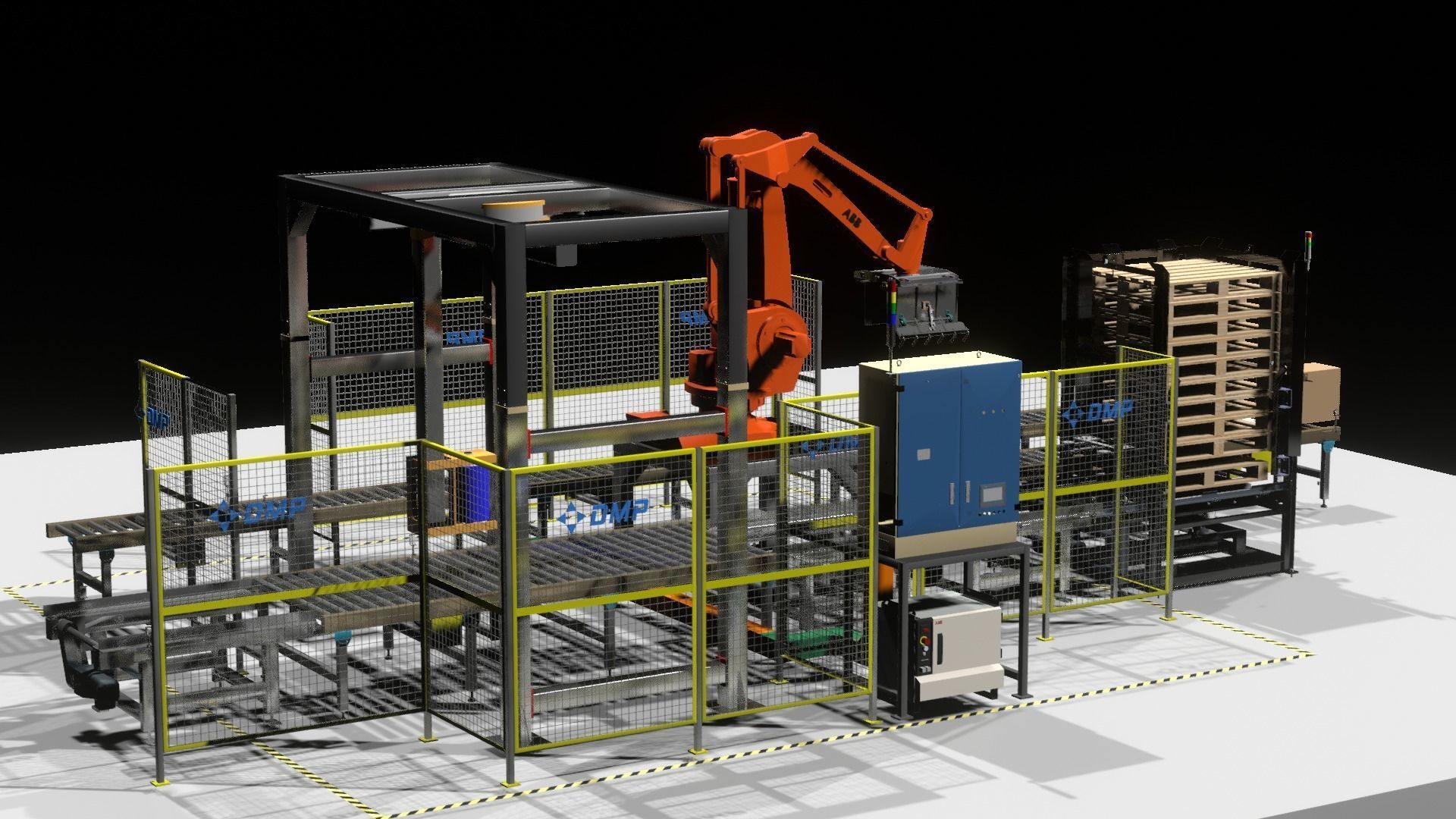

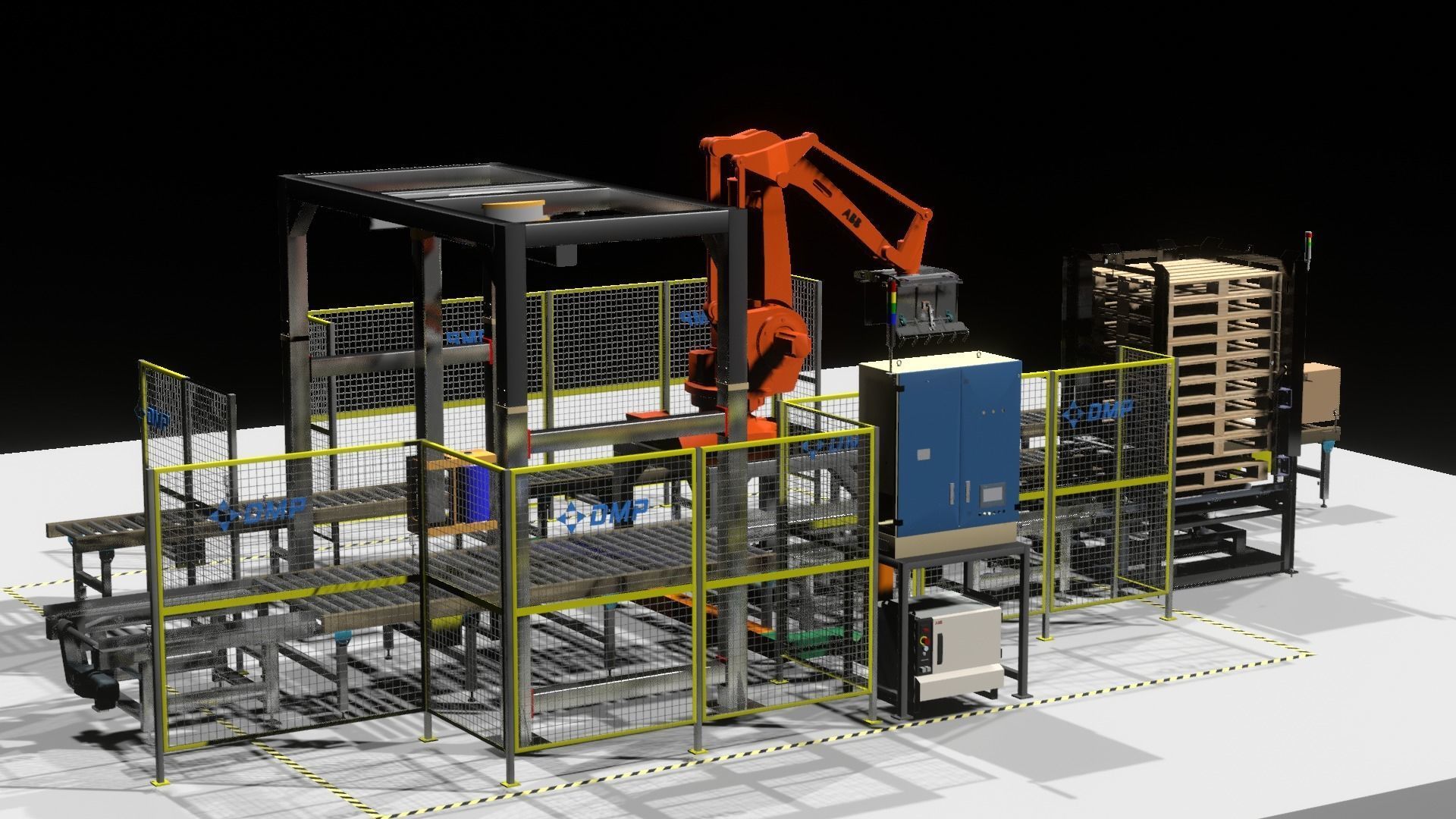

FULL Line Robot Palletizer Industrial - DMP Project ABB 660 Low-poly 3D model

FULL Line Robot Palletizer Station - ABB 660 - 180/250 with specialized equipment and systems to ensure precise and efficient operation. Below is a detailed description of the equipment and systems used on the robot palletizer station:

Air compressor: An air compressor is integrated into the robot palletizer station to supply compressed air for the robot's operation. Compressed air can be used to control the robot's joints or to create vacuum suction to hold the product. This helps increase the accuracy and efficiency of the robot.

Amplifier: An amplifier is used to enhance the control signal of the robot palletizer. The amplifier improves the accuracy and sensitivity of the robot, helping to increase efficiency and ensure stable operation.

Vacuum system: A vacuum system is used to securely hold the product on the robot palletizer. This system includes vacuum suction cups, filters, and a compressed air system to create vacuum suction. This ensures that the product is securely held on the robot and avoids falling during transportation.

Positioning system: The positioning system is used to determine the position of the pallet and the product on the pallet. This system includes sensors and measuring devices for accurate positioning. This ensures that the product is accurately stacked on the pallet and reduces incidents during transportation.

Safety equipment: FULL Line Robot Palletizer Station - ABB 660 - 180/250 is equipped with safety equipment including safety sensors, safety switches, shock-absorbing components, and other equipment to ensure safety for users and machinery. This ensures safety during operation and reduces the risk of accidents.