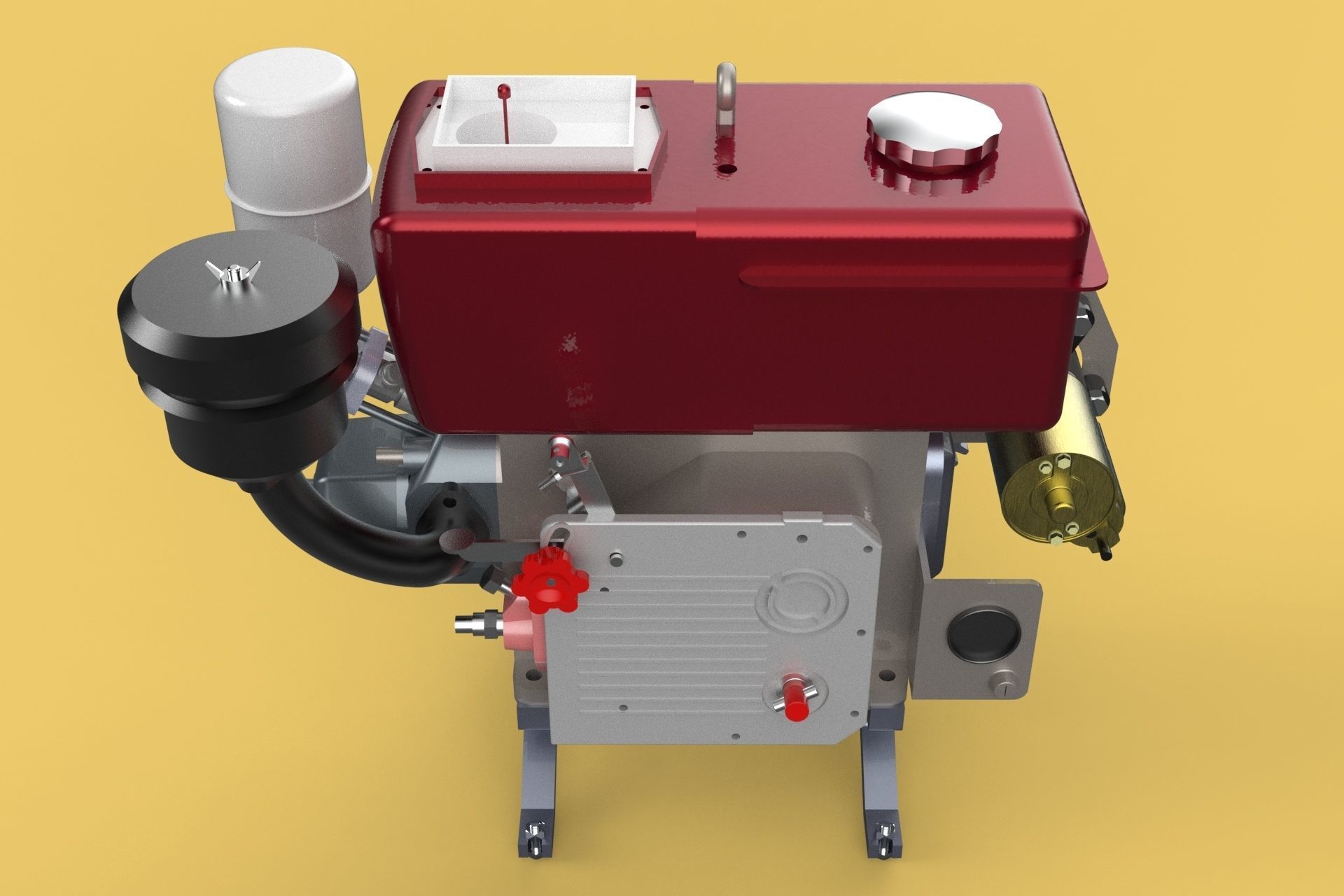

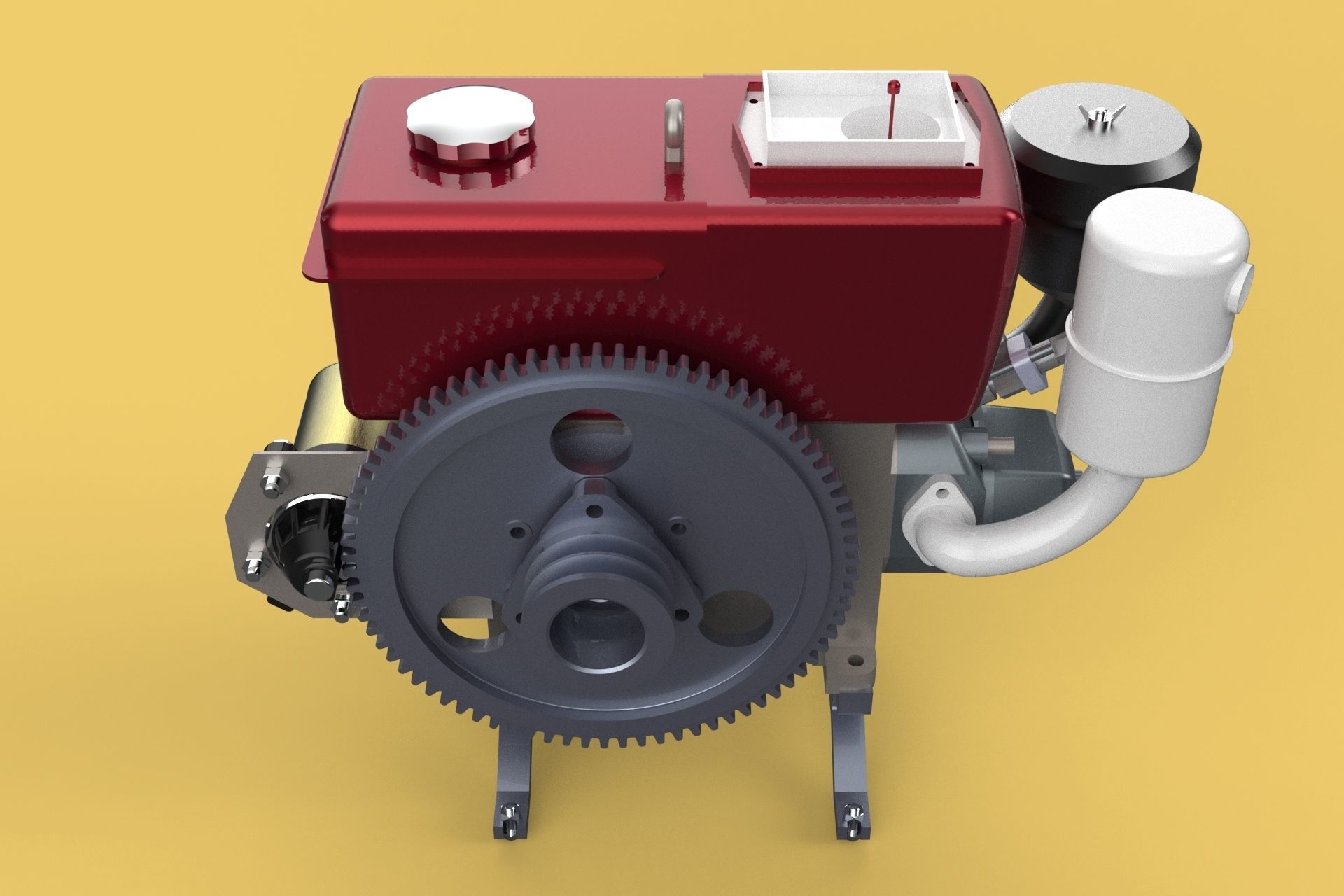

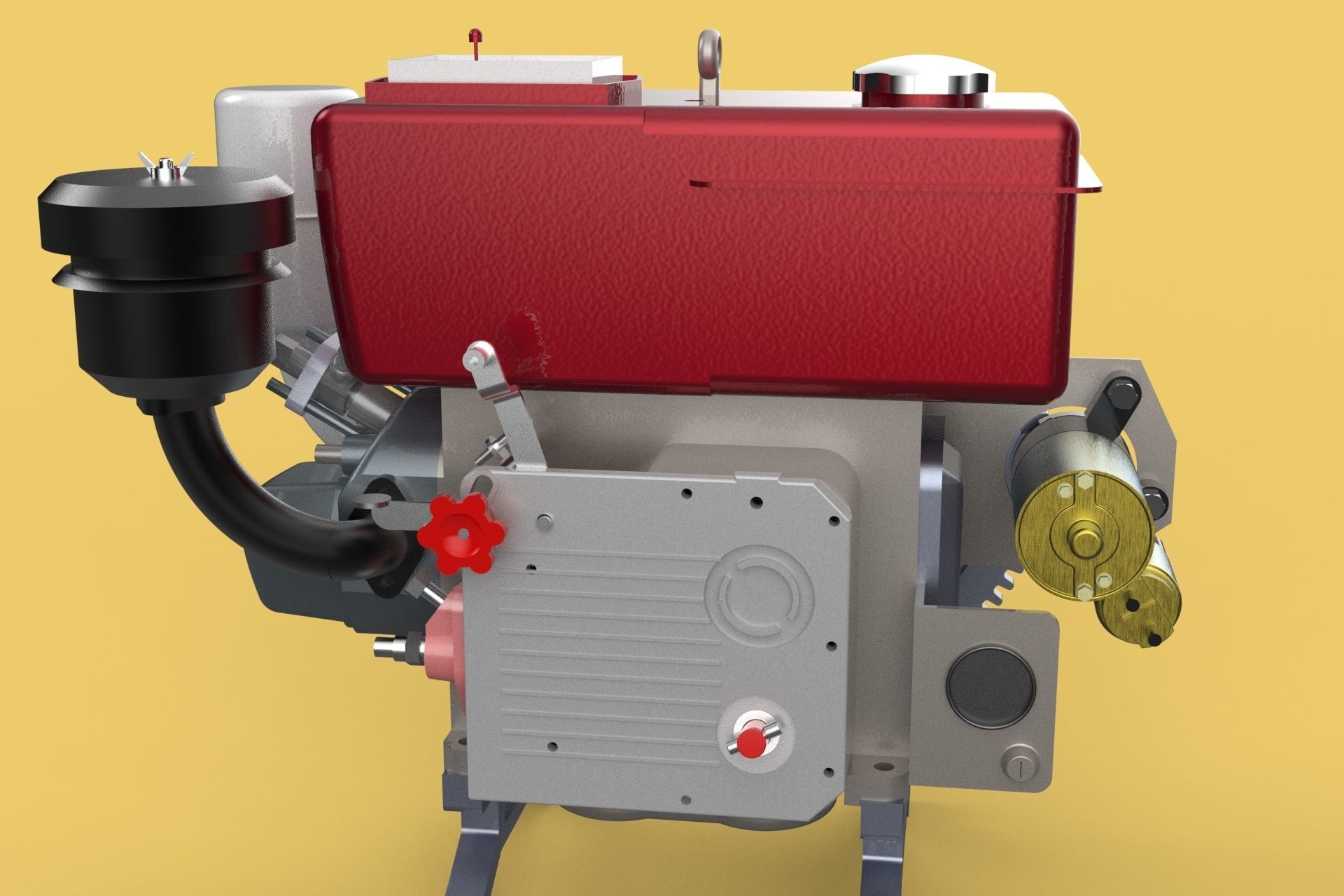

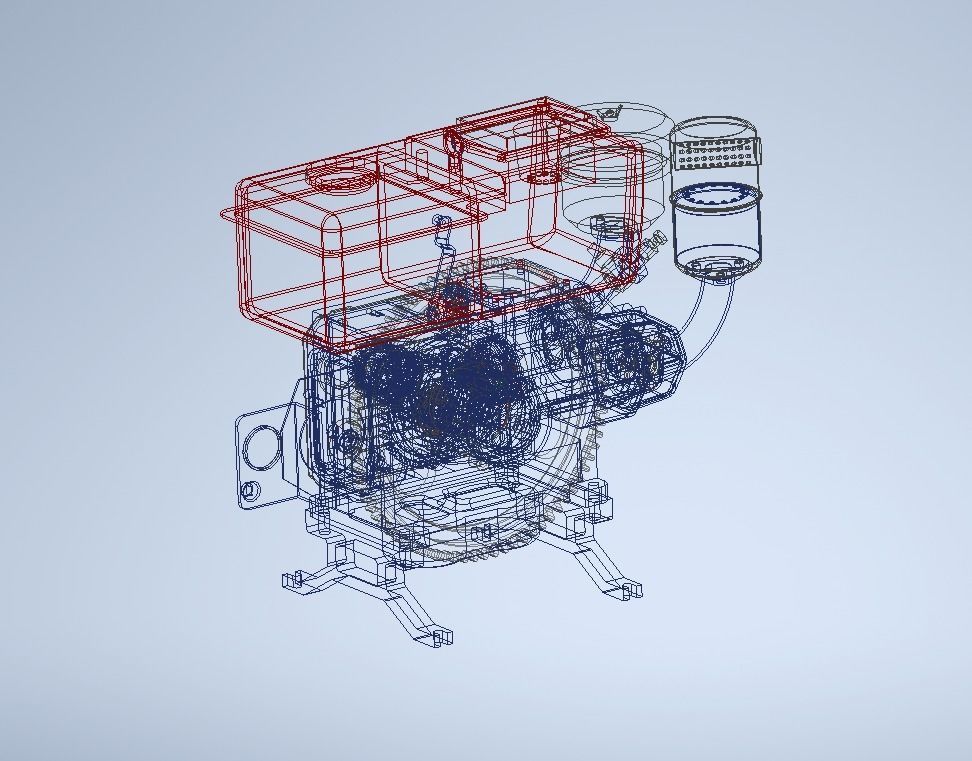

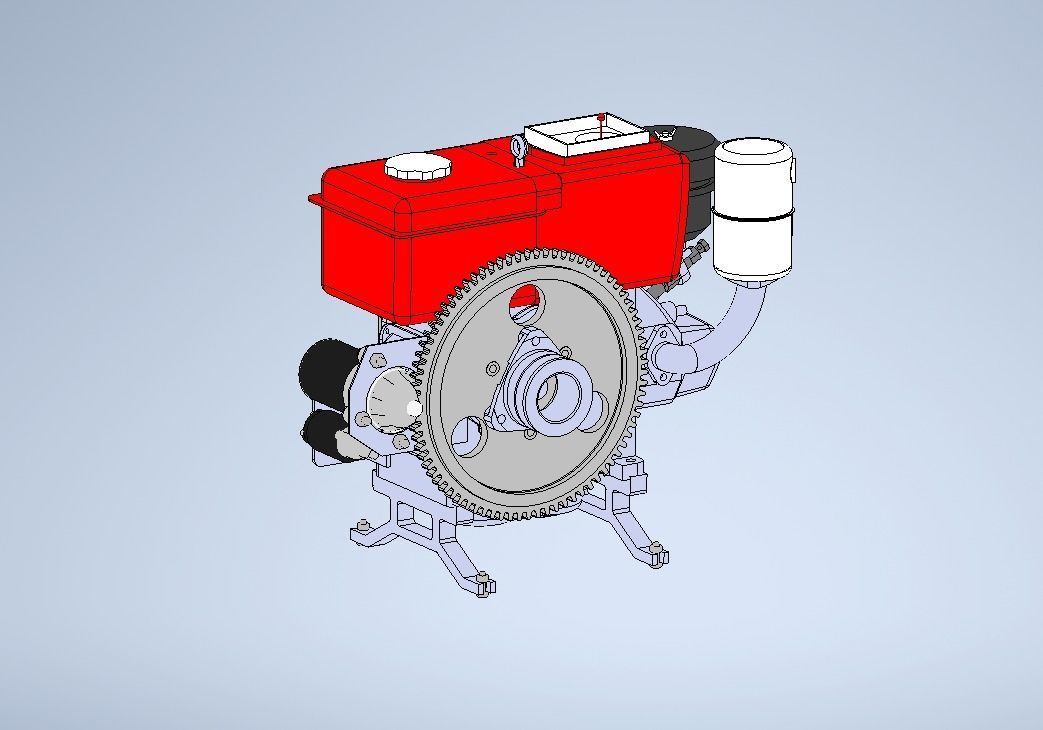

DIESEL ENGINE MACHINE DONGFENG 3D model

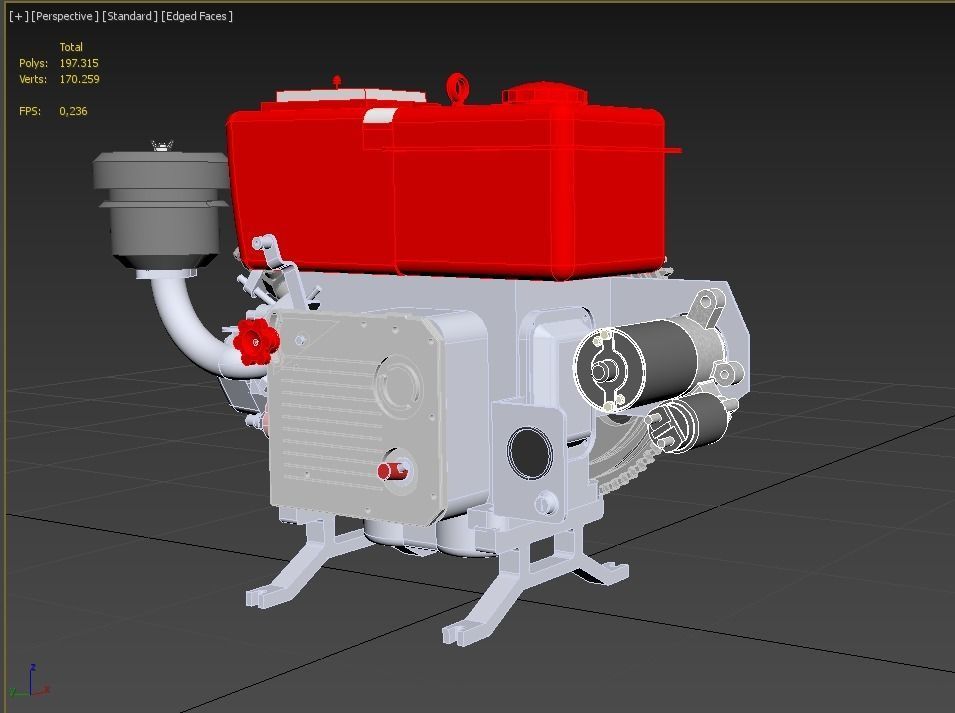

The model contains the most popular formats:

- 3DS MAX: *.max

- Blender: *.blend

- Rhinoceros: *.3dm

- SketchUp: *.skp

- Wavefront OBJ: *.obj *.mtl (Multi Format)

- FBX: *.fbx (Multi Format)

- STEP: *.step *.stp (NURBS)

- IGES: *.iges *.igs (NURBS)

- ACIS: *.sat (NURBS)

- 3DS MAX all ver.: *.3ds (Multi Format)

- Stereolithography: *.stl

- AutoCAD: *.dwg

- Each file was checked for opening and full content by the model.

- The 3D model was created on real base. It’s created accurately, in real units of measurement, qualitatively and maximally close to the original.

- Renders Are made in Luxion Keyshot

- “WE PROVIDE 3D MODEL CHEAP PRICE BUT WITH GOOD QUALITY”

- If you need any other formats we are more than happy to make them for you. Contact me for any question :)

Sincerely Your, SURF3DMORE INFORMATION ABOUT 3D MODELS :THE DIESEL ENGINE, NAMED AFTER RUDOLF DIESEL, IS AN INTERNAL COMBUSTION ENGINE IN WHICH IGNITION OF THE FUEL IS CAUSED BY THE ELEVATED TEMPERATURE OF THE AIR IN THE CYLINDER DUE TO MECHANICAL COMPRESSION; THUS, THE DIESEL ENGINE IS CALLED A COMPRESSION-IGNITION ENGINE (CI ENGINE). THIS CONTRASTS WITH ENGINES USING SPARK PLUG-IGNITION OF THE AIR-FUEL MIXTURE, SUCH AS A PETROL ENGINE (GASOLINE ENGINE) OR A GAS ENGINE (USING A GASEOUS FUEL LIKE NATURAL GAS OR LIQUEFIED PETROLEUM GAS).

INTRODUCTIONDIESEL ENGINES WORK BY COMPRESSING ONLY AIR, OR AIR PLUS RESIDUAL COMBUSTION GASES FROM THE EXHAUST (KNOWN AS EXHAUST GAS RECIRCULATION, EGR). AIR IS INDUCTED INTO THE CHAMBER DURING THE INTAKE STROKE, AND COMPRESSED DURING THE COMPRESSION STROKE. THIS INCREASES THE AIR TEMPERATURE INSIDE THE CYLINDER SO THAT ATOMISED DIESEL FUEL INJECTED INTO THE COMBUSTION CHAMBER IGNITES. WITH THE FUEL BEING INJECTED INTO THE AIR JUST BEFORE COMBUSTION, THE DISPERSION OF THE FUEL IS UNEVEN; THIS IS CALLED A HETEROGENEOUS AIR-FUEL MIXTURE. THE TORQUE A DIESEL ENGINE PRODUCES IS CONTROLLED BY MANIPULATING THE AIR-FUEL RATIO (Λ); INSTEAD OF THROTTLING THE INTAKE AIR, THE DIESEL ENGINE RELIES ON ALTERING THE AMOUNT OF FUEL THAT IS INJECTED, AND THE AIR-FUEL RATIO IS USUALLY HIGH.

THE DIESEL ENGINE HAS THE HIGHEST THERMAL EFFICIENCY (ENGINE EFFICIENCY) OF ANY PRACTICAL INTERNAL OR EXTERNAL COMBUSTION ENGINE DUE TO ITS VERY HIGH EXPANSION RATIO AND INHERENT LEAN BURN WHICH ENABLES HEAT DISSIPATION BY THE EXCESS AIR. A SMALL EFFICIENCY LOSS IS ALSO AVOIDED COMPARED WITH NON-DIRECT-INJECTION GASOLINE ENGINES SINCE UNBURNED FUEL IS NOT PRESENT DURING VALVE OVERLAP AND THEREFORE NO FUEL GOES DIRECTLY FROM THE INTAKE/INJECTION TO THE EXHAUST. LOW-SPEED DIESEL ENGINES (AS USED IN SHIPS AND OTHER APPLICATIONS WHERE OVERALL ENGINE WEIGHT IS RELATIVELY UNIMPORTANT) CAN REACH EFFECTIVE EFFICIENCIES OF UP TO 55%.[1] THE COMBINED CYCLE GAS TURBINE (BRAYTON AND RANKINE CYCLE) IS A COMBUSTION ENGINE THAT IS MORE EFFICIENT THAN A DIESEL ENGINE, BUT IT IS, DUE TO ITS MASS AND DIMENSIONS, UNSUITED FOR VEHICLES, WATERCRAFT, OR AIRCRAFT. THE WORLD'S LARGEST DIESEL ENGINES PUT IN SERVICE ARE 14-CYLINDER, TWO-STROKE MARINE DIESEL ENGINES; THEY PRODUCE A PEAK POWER OF ALMOST 100 MW EACH.[2]

DIESEL ENGINES MAY BE DESIGNED WITH EITHER TWO-STROKE OR FOUR-STROKE COMBUSTION CYCLES. THEY WERE ORIGINALLY USED AS A MORE EFFICIENT REPLACEMENT FOR STATIONARY STEAM ENGINES. SINCE THE 1910S, THEY HAVE BEEN USED IN SUBMARINES AND SHIPS. USE IN LOCOMOTIVES, BUSES, TRUCKS, HEAVY EQUIPMENT, AGRICULTURAL EQUIPMENT AND ELECTRICITY GENERATION PLANTS FOLLOWED LATER. IN THE 1930S, THEY SLOWLY BEGAN TO BE USED IN A FEW AUTOMOBILES. SINCE THE 1970S ENERGY CRISIS, DEMAND FOR HIGHER FUEL EFFICIENCY HAS RESULTED IN MOST MAJOR AUTOMAKERS, AT SOME POINT, OFFERING DIESEL-POWERED MODELS, EVEN IN VERY SMALL CARS.[3][4] ACCORDING TO KONRAD REIF (2012), THE EU AVERAGE FOR DIESEL CARS AT THE TIME ACCOUNTED FOR HALF OF NEWLY REGISTERED CARS.[5] HOWEVER, AIR POLLUTION EMISSIONS ARE HARDER TO CONTROL IN DIESEL ENGINES THAN IN GASOLINE ENGINES, SO THE USE OF DIESEL AUTO ENGINES IN THE U.S. IS NOW LARGELY RELEGATED TO LARGER ON-ROAD AND OFF-ROAD VEHICLES.

THOUGH AVIATION HAS TRADITIONALLY AVOIDED DIESEL ENGINES, AIRCRAFT DIESEL ENGINES HAVE BECOME INCREASINGLY AVAILABLE IN THE 21ST CENTURY. SINCE THE LATE 1990S, FOR VARIOUS REASONS – INCLUDING THE DIESEL'S NORMAL ADVANTAGES OVER GASOLINE ENGINES, BUT ALSO FOR RECENT ISSUES PECULIAR TO AVIATION – DEVELOPMENT AND PRODUCTION OF DIESEL ENGINES FOR AIRCRAFT HAS SURGED, WITH OVER 5,000 SUCH ENGINES DELIVERED WORLDWIDE BETWEEN 2002 AND 2018, PARTICULARLY FOR LIGHT AIRPLANES AND UNMANNED AERIAL VEHICLES.