1/20

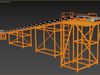

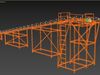

The model contains the most popular formats:

- 3DS MAX: *.max

- Blender: *.blend

- Rhinoceros: *.3dm

- SketchUp: *.skp

- Wavefront OBJ: *.obj *.mtl (Multi Format)

- FBX: *.fbx (Multi Format)

- STEP: *.step *.stp (NURBS)

- IGES: *.iges *.igs (NURBS)

- ACIS: *.sat (NURBS)

- 3DS MAX all ver.: *.3ds (Multi Format)

- Stereolithography: *.stl

- AutoCAD: *.dwg

- Each file was checked for opening and full content by the model.

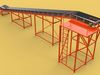

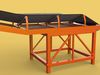

- The 3D model was created on real base. It’s created accurately, in real units of measurement, qualitatively and maximally close to the original.

- Renders Are made in Luxion Keyshot

- “WE PROVIDE 3D MODEL CHEAP PRICE BUT WITH GOOD QUALITY”

- If you need any other formats we are more than happy to make them for you. Contact me for any question :)

Sincerely Your, SURF3DMORE INFORMATION ABOUT 3D MODELS :A carrier belt conveyor, also known as a belt conveyor in industrial settings, is a fundamental piece of equipment for moving materials horizontally or at slight inclines. Here's a breakdown of its components and uses:Components:Belt: The heart of the conveyor, it's a continuous loop made of strong, flexible materials like rubber, canvas, or steel mesh. The belt type depends on the material being conveyed (abrasive items might need a steel mesh belt for durability).Carriers: These are often metal structures supporting the belt at regular intervals. They can be rollers for smooth movement or troughing idlers that curve the belt slightly to create a bowl for better containment of materials like powders or small parts.Pulleys: Grooved wheels at each end of the conveyor that the belt wraps around. One pulley is driven by a motor to create movement.Drive System: The motor and gearbox that provide power to the conveyor belt.Frame: The supporting structure for the entire conveyor, often made of steel for sturdiness.Applications:Bulk Material Handling: In industries like mining, aggregates, and agriculture, carrier belt conveyors move large quantities of loose materials like coal, sand, gravel, or grain.Manufacturing Production Lines: They efficiently transport parts, products, or sub-assemblies between different stages of production within a factory.Packaging Lines: Flat belt conveyors can move packaged goods for labeling, sorting, or palletizing.Advantages:High Capacity: Can handle large volumes of materials continuously.Versatility: Adaptable to various lengths, inclines, and belt types for diverse applications.Durability: Built to withstand demanding industrial environments.Cost-Effective: Relatively low maintenance compared to other material handling systems.

REVIEWS & COMMENTS

accuracy, and usability.