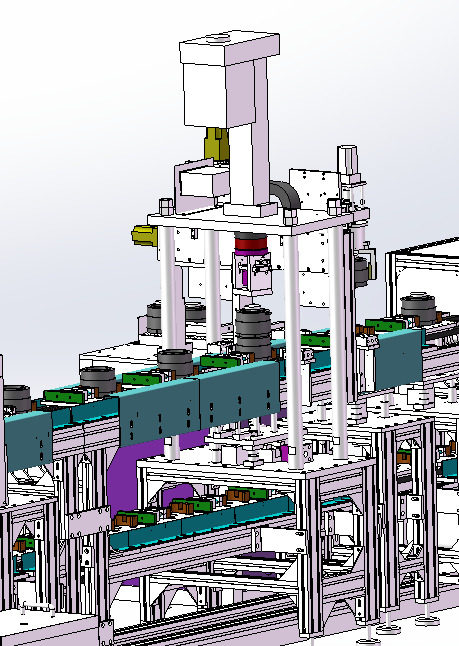

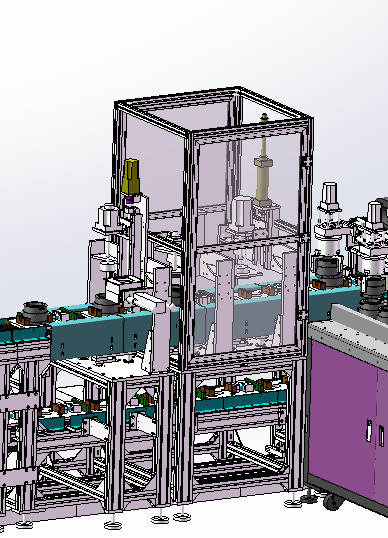

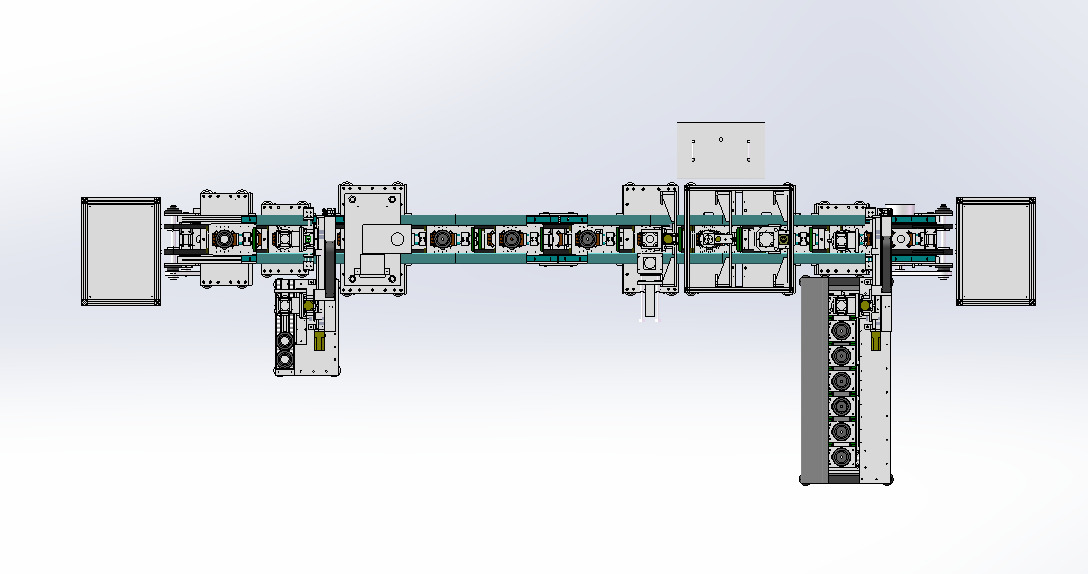

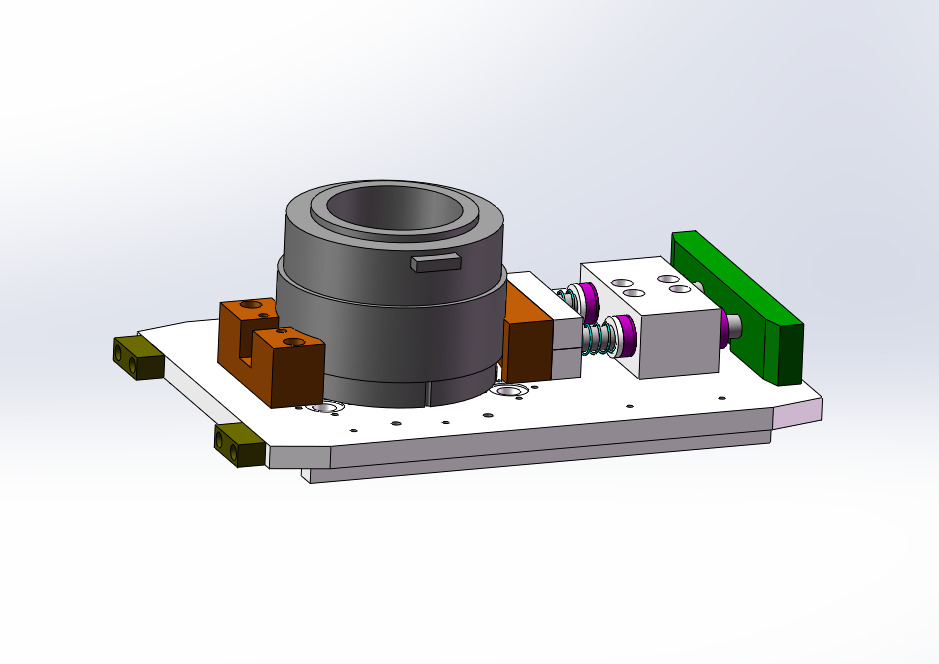

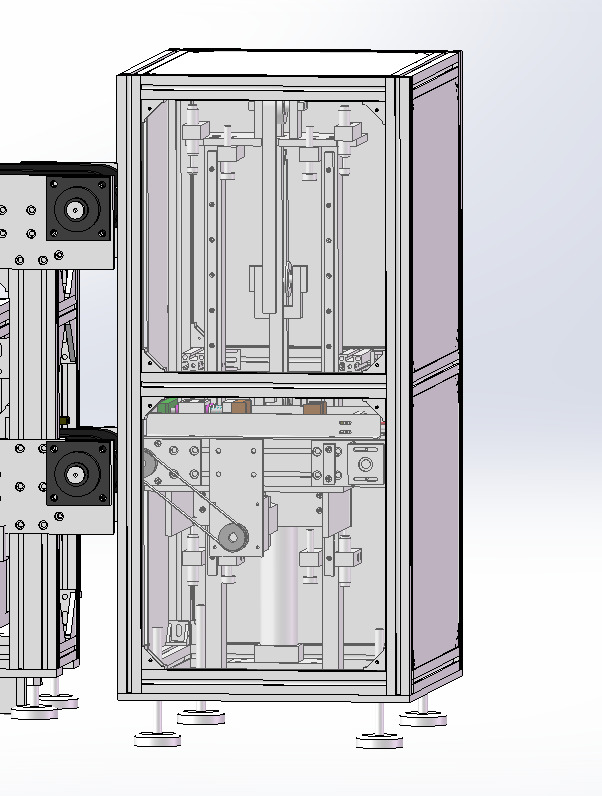

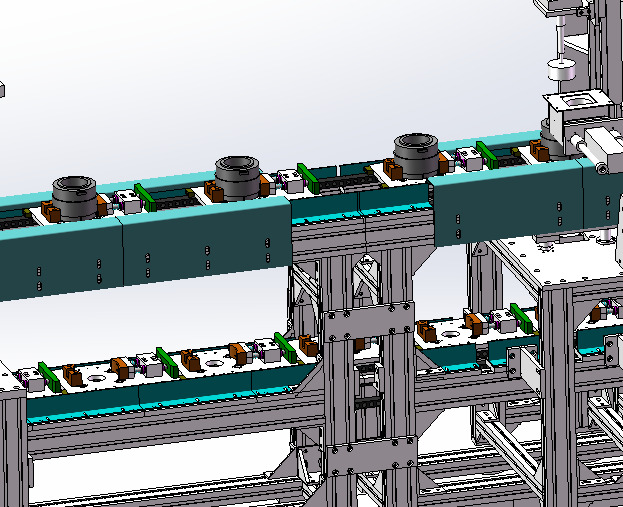

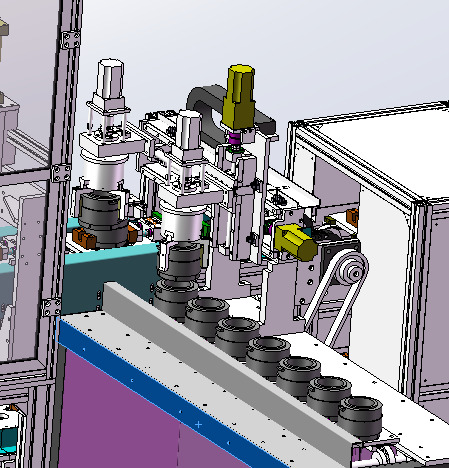

Automatic Motor Assembly Line 3D model

This is an automatic assembly line for high - power plastic - encapsulated motors. The working principle and sequence of actions are as follows:A. The special tooling plates enter the tooling plate storage area from the lifting platform.B. When the tooling plate for placing the BMC stators is empty, the tooling plate enters this station from the storage area. (The stopper blocks the tooling plate, and the tooling plate stops. The same applies hereinafter.) The manipulator places two sets of BMC stators respectively in the corresponding positions of the special tooling plate. After stepping on the foot switch, the tooling plate moves downwards and enters the next storage area.C. When the station for placing the rotor, PG board, and BB cover is empty, the tooling plate automatically enters this station. Then, by stepping on the foot switch, the tooling plate automatically moves to the temporary storage area of the next station.D. When the station for pressing the BB cover is empty, the tooling plate automatically enters this station to automatically press the BB cover and detect the axial play, etc. After pressing is completed, by stepping on the foot switch, the tooling plate automatically moves to the next station for temporary storage.E. When the performance testing station is empty, the tooling plate automatically moves to this station. The performance is manually tested. After the performance test is completed, by stepping on the foot switch, the tooling plate automatically moves to the storage area of the tooling plate lifting platform.F. Execute the next cycle.