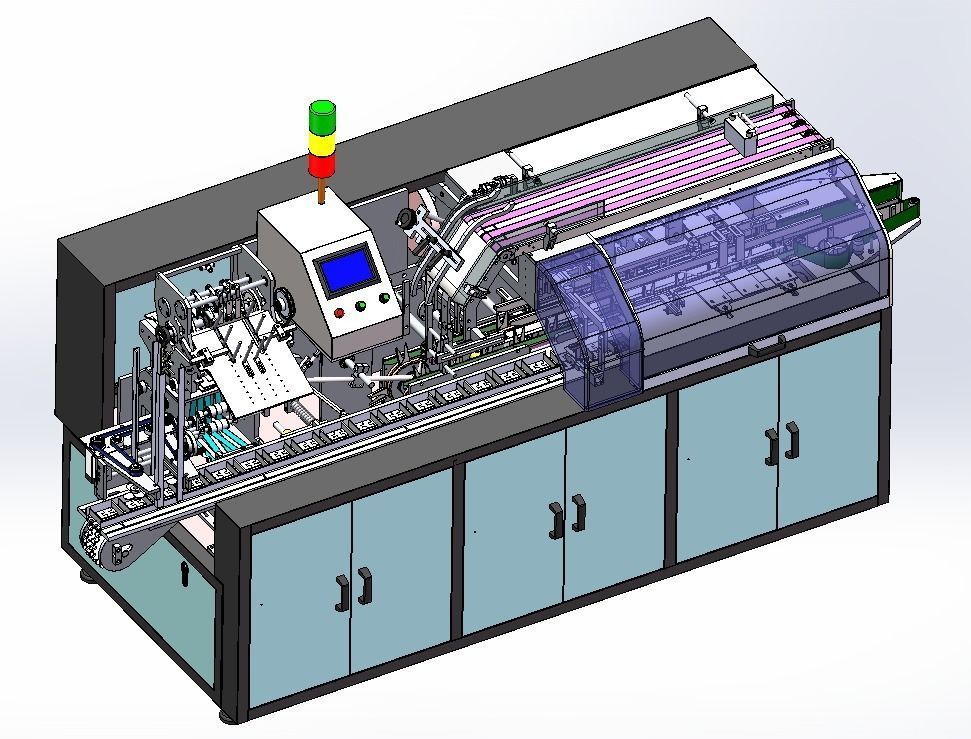

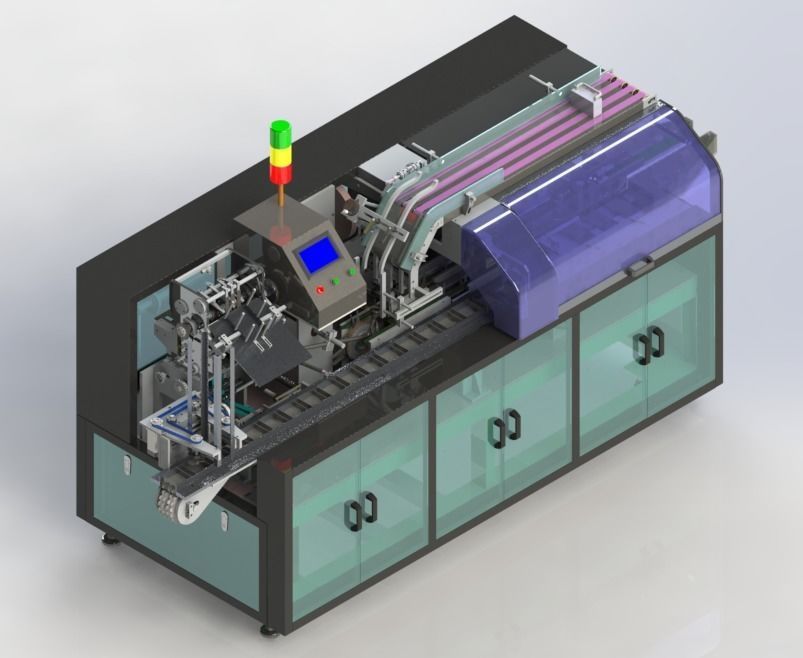

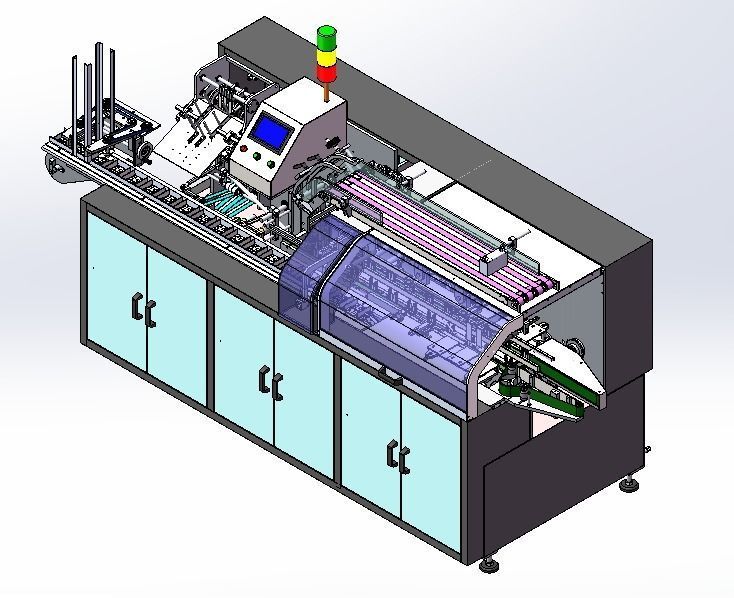

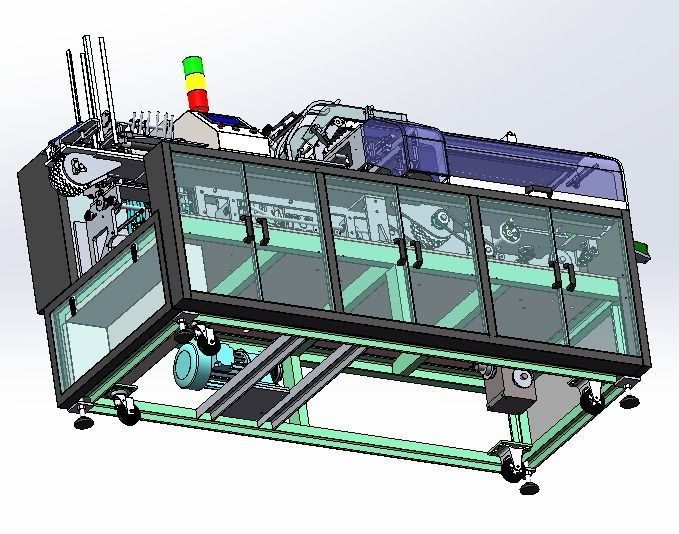

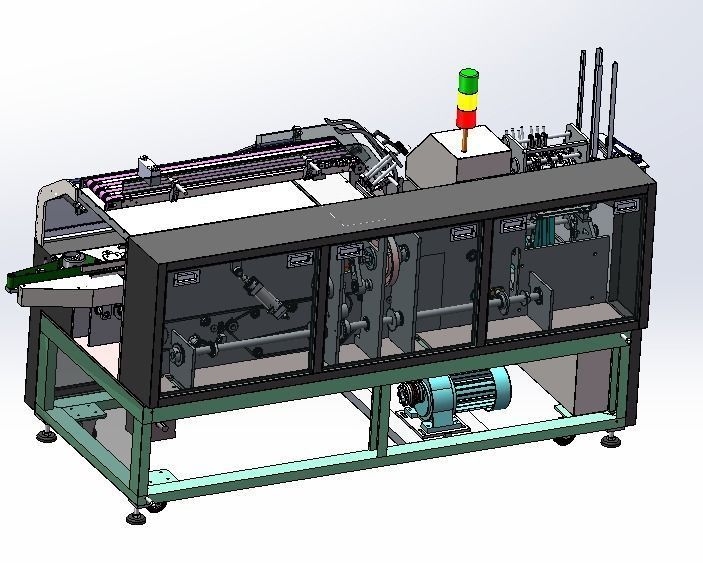

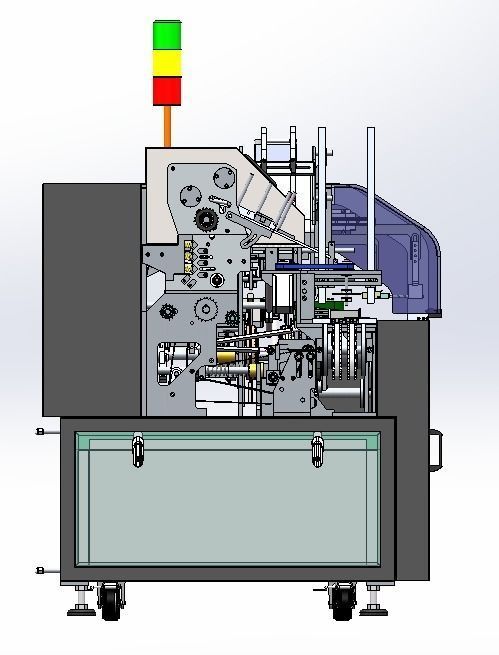

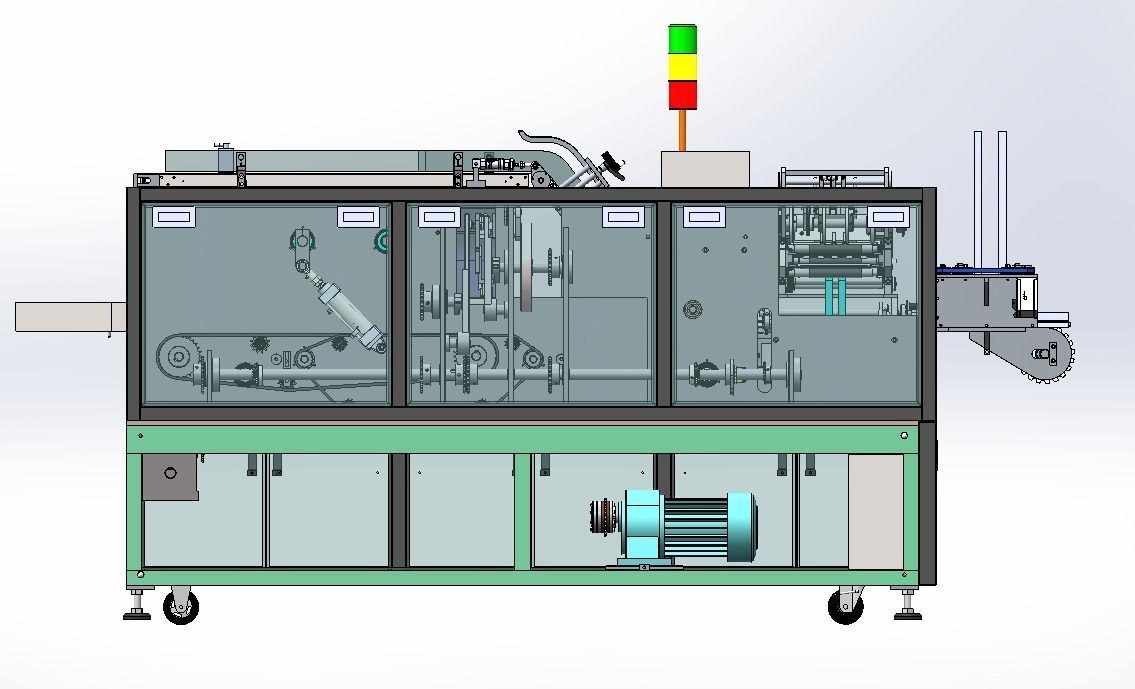

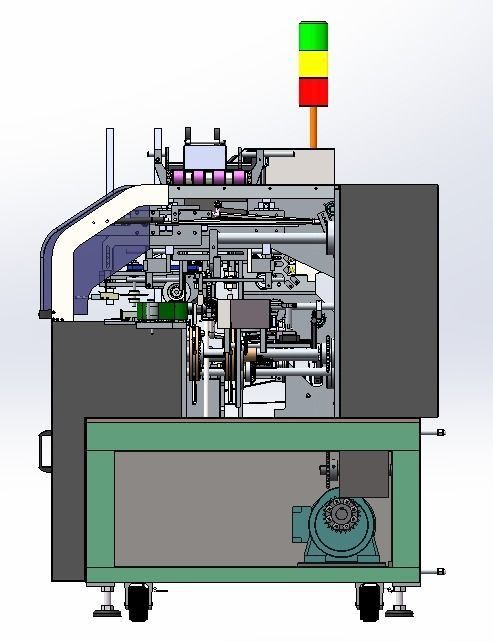

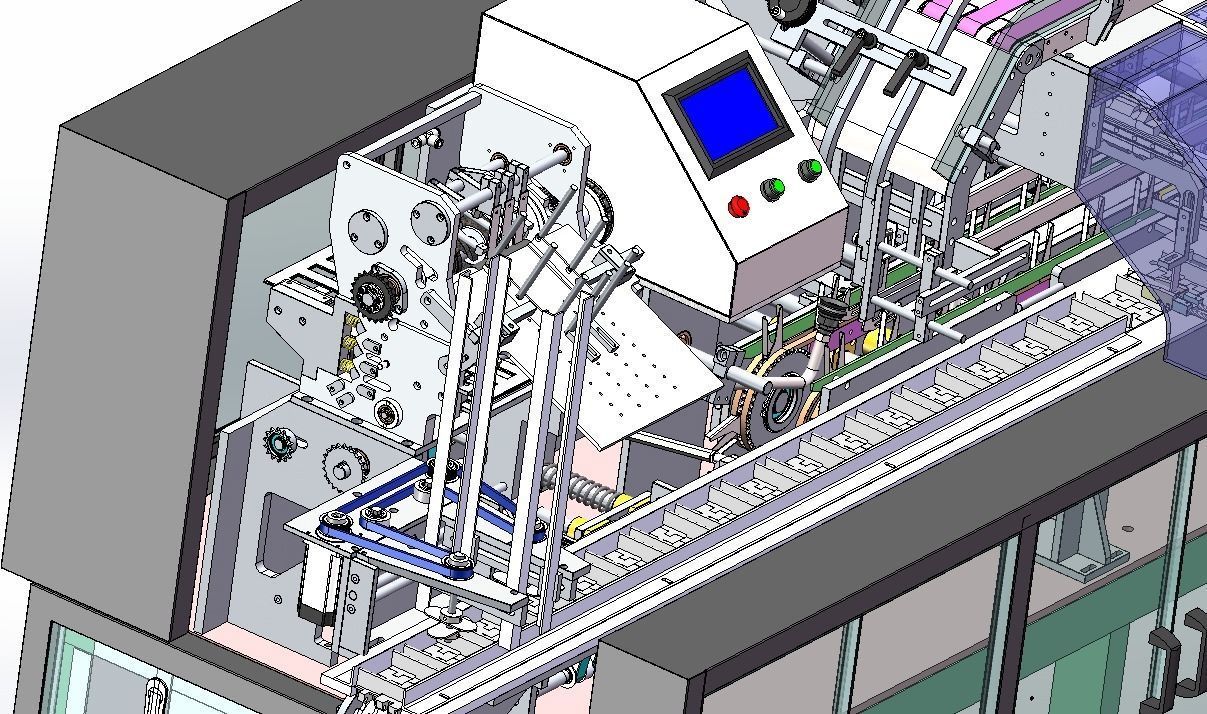

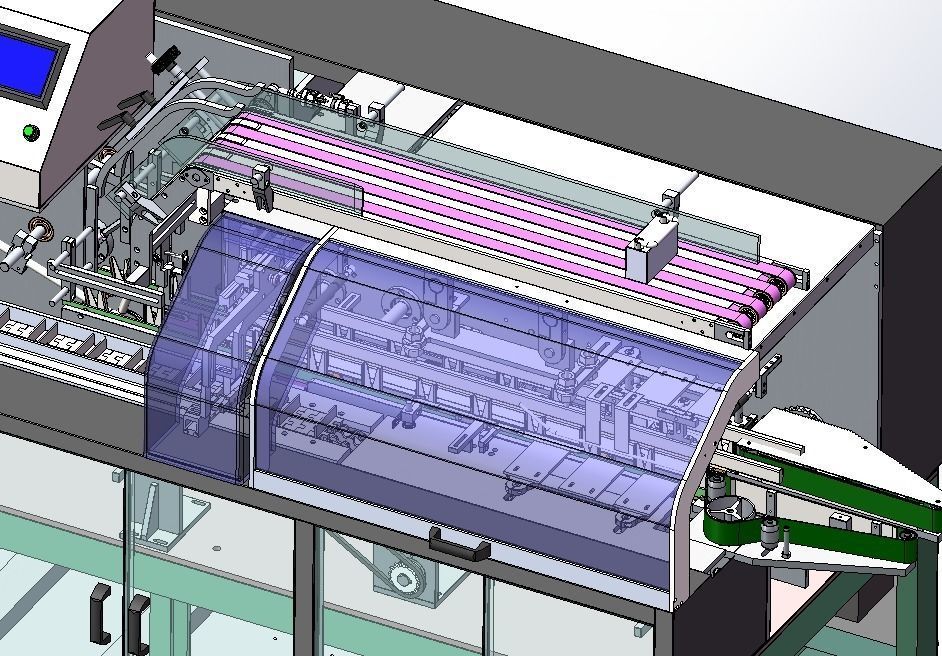

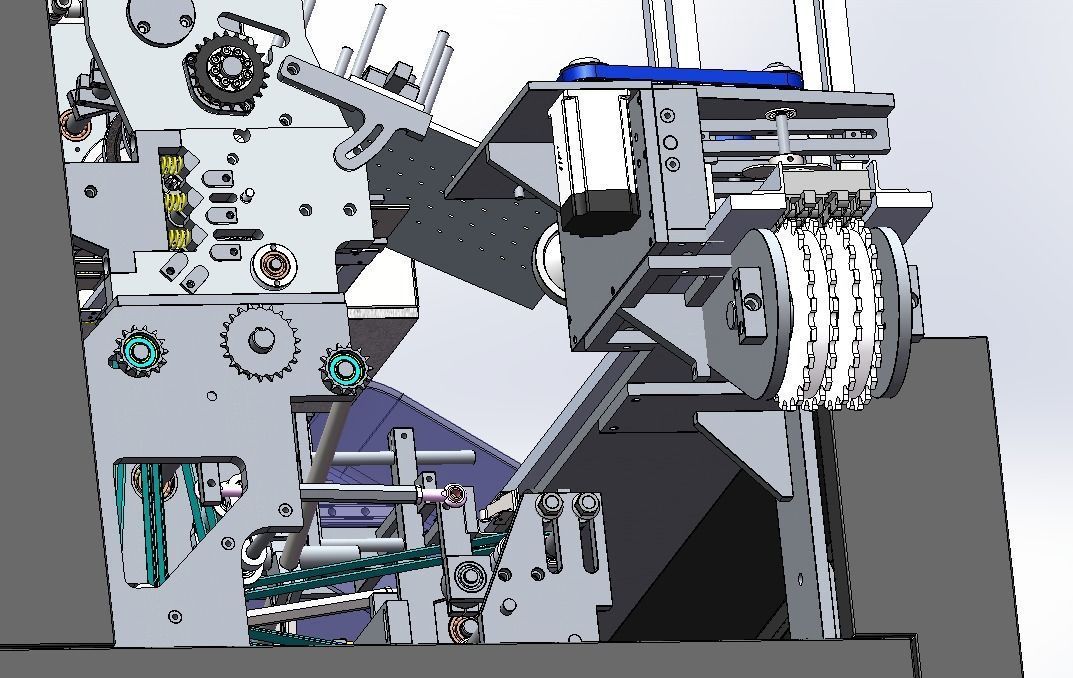

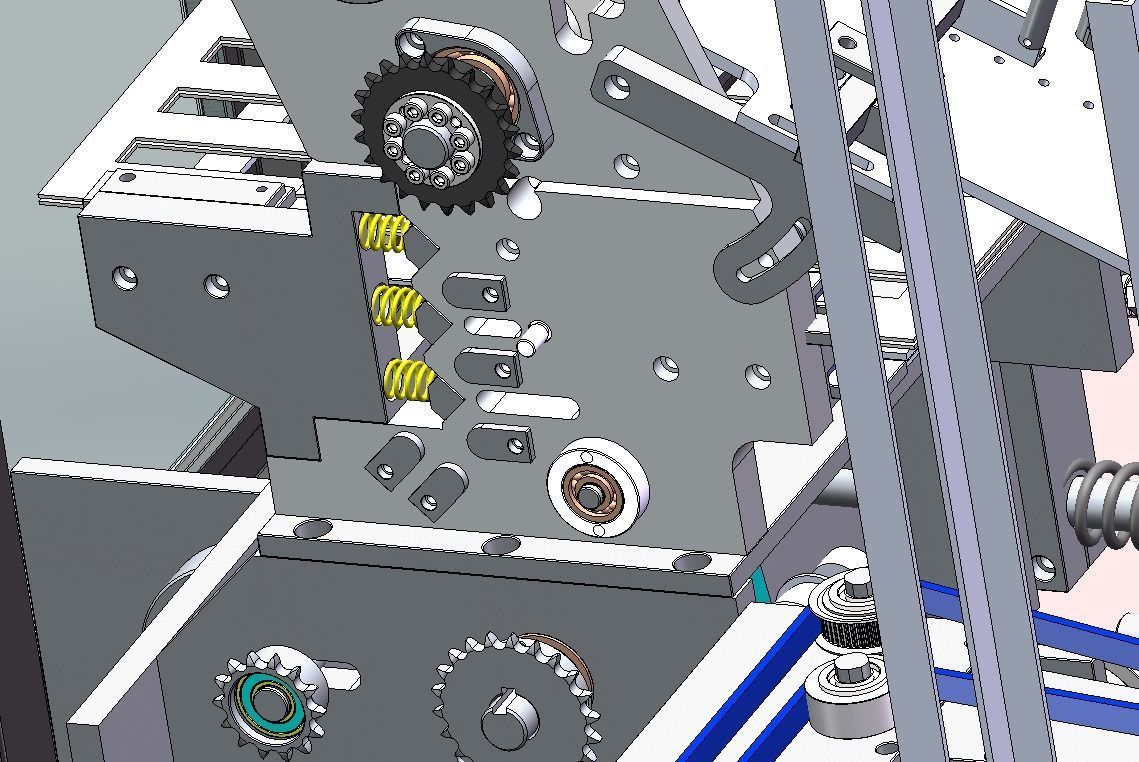

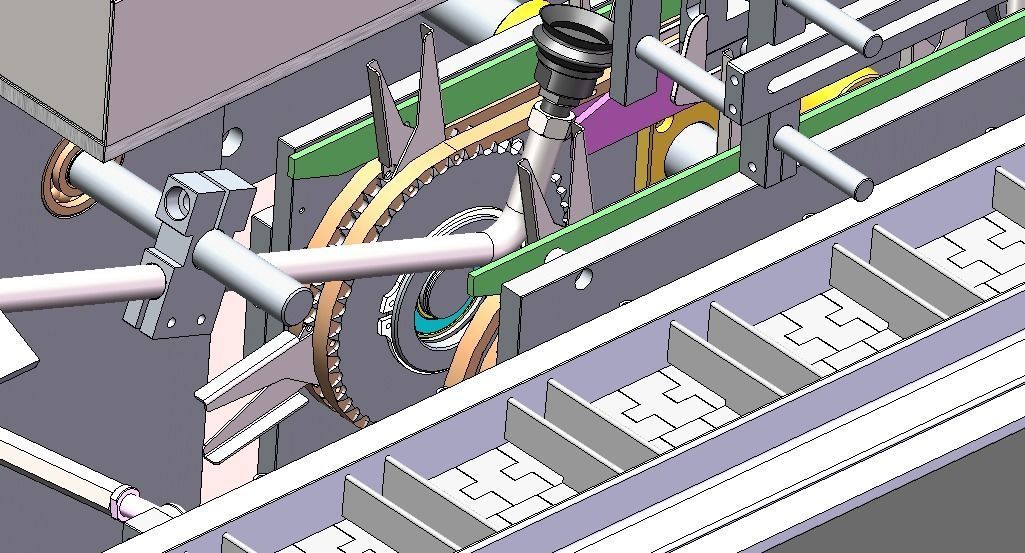

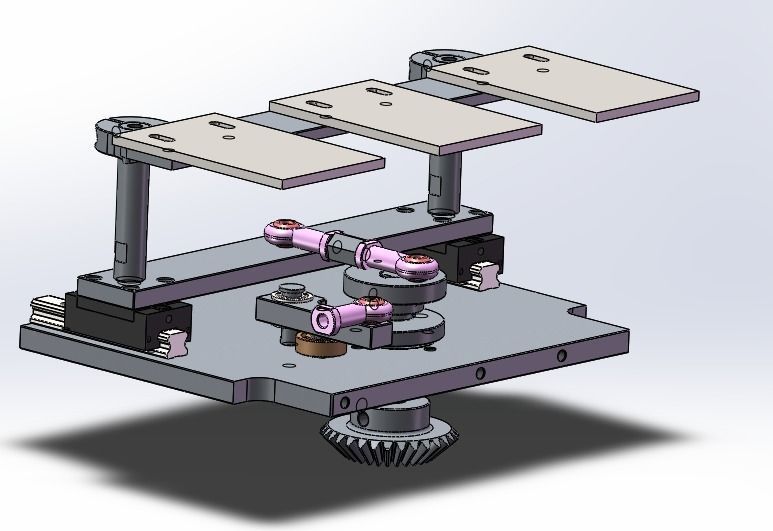

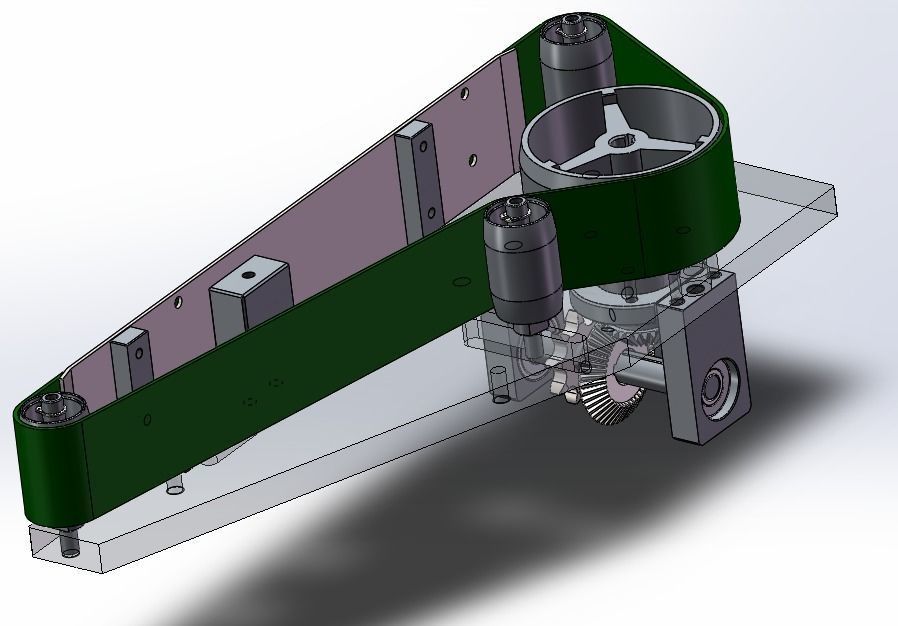

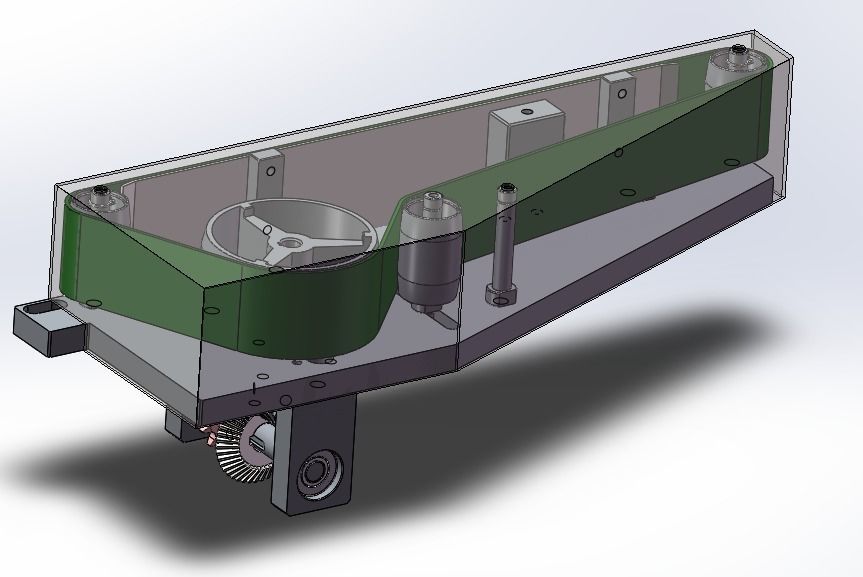

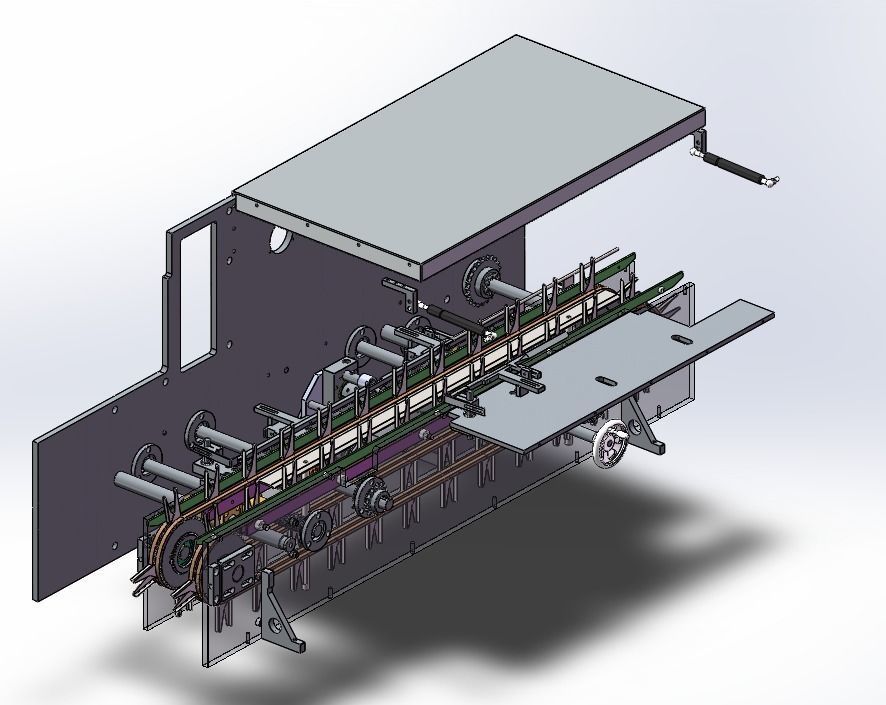

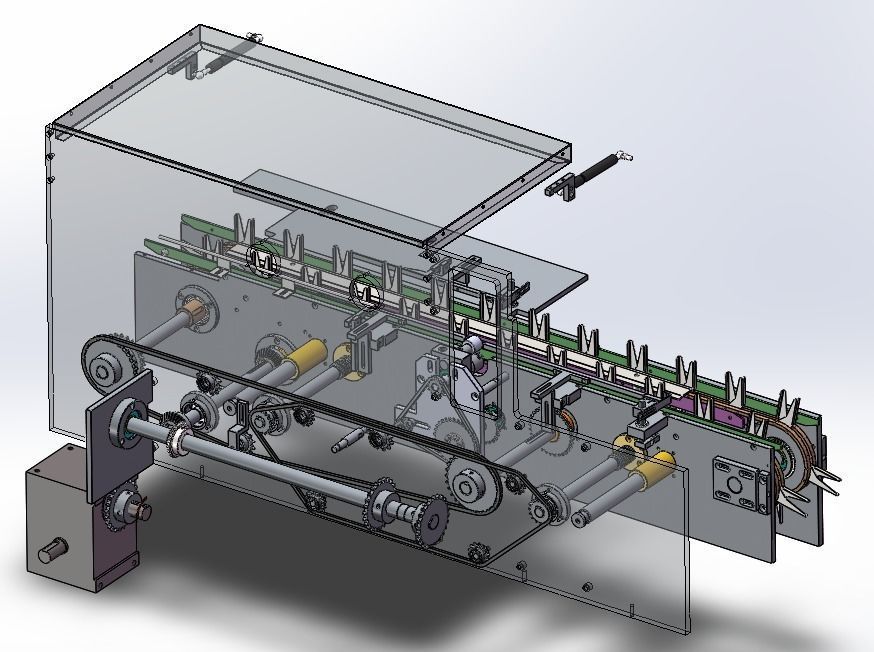

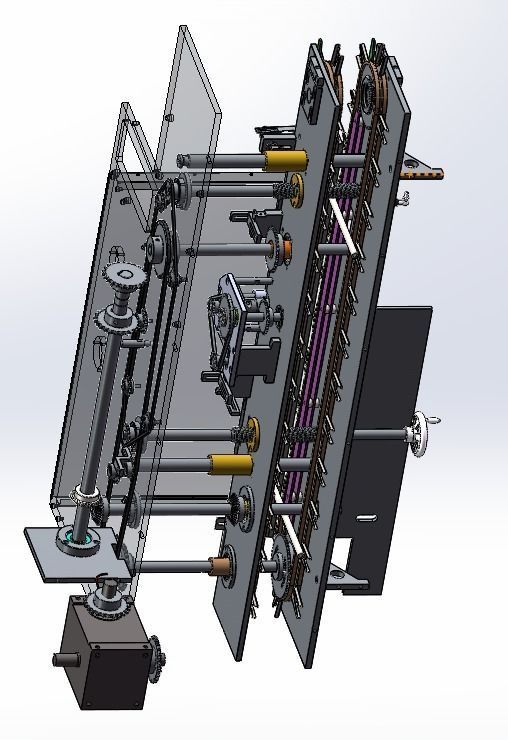

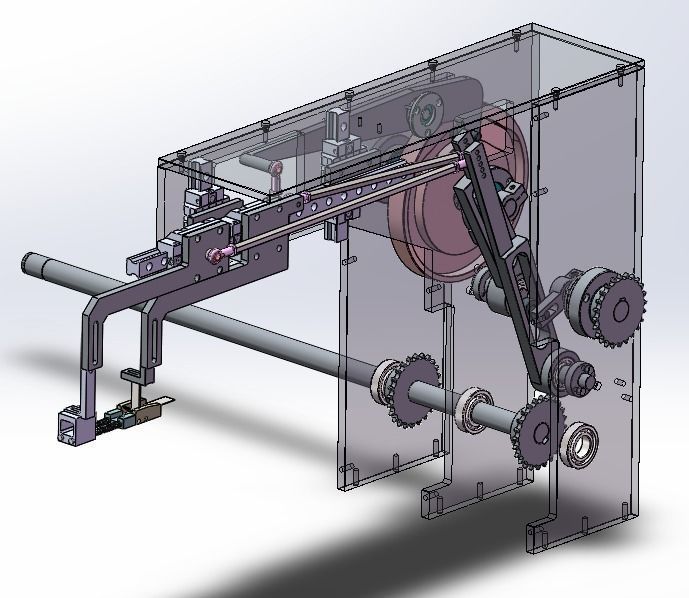

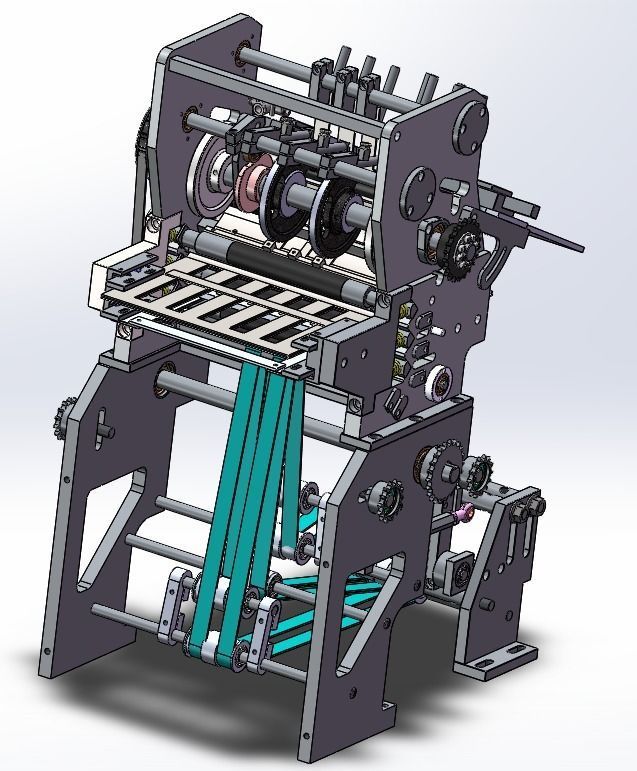

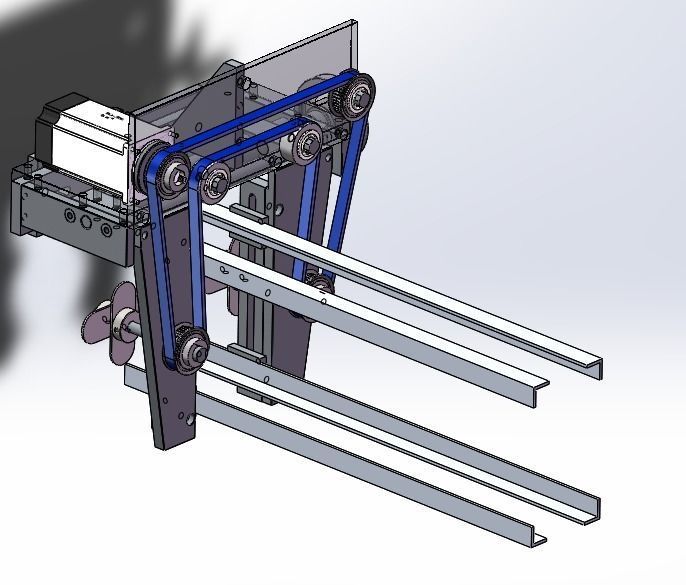

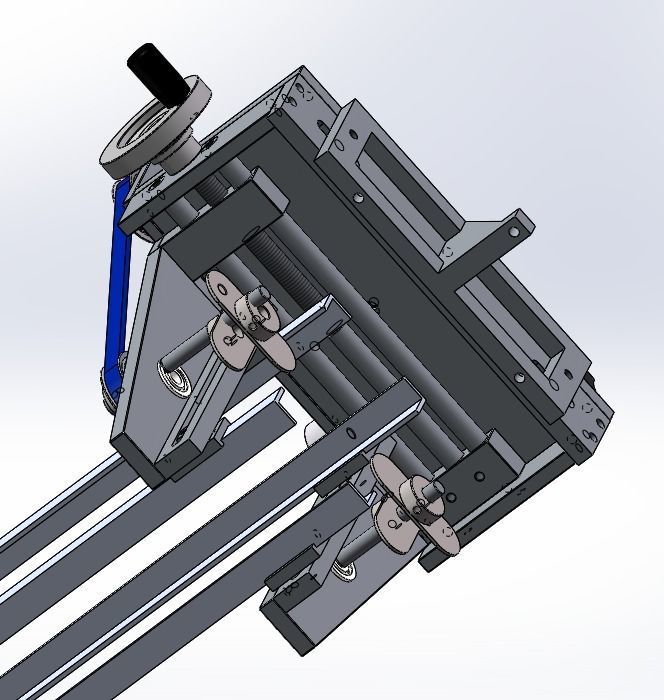

Automatic high-speed cartoning machine 3D model

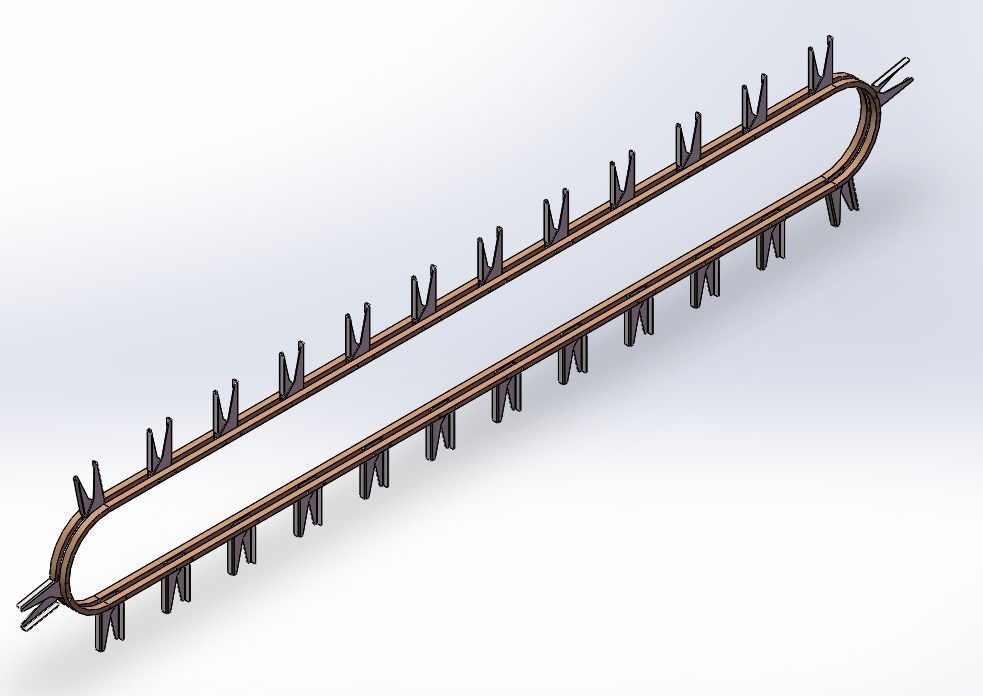

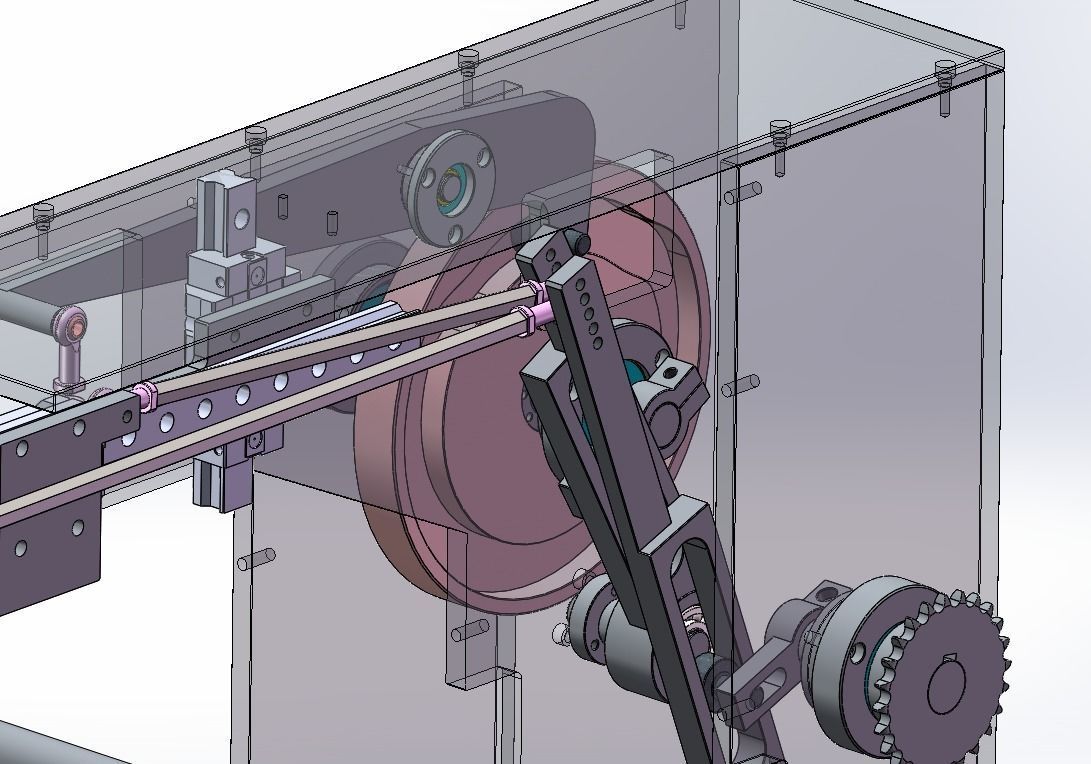

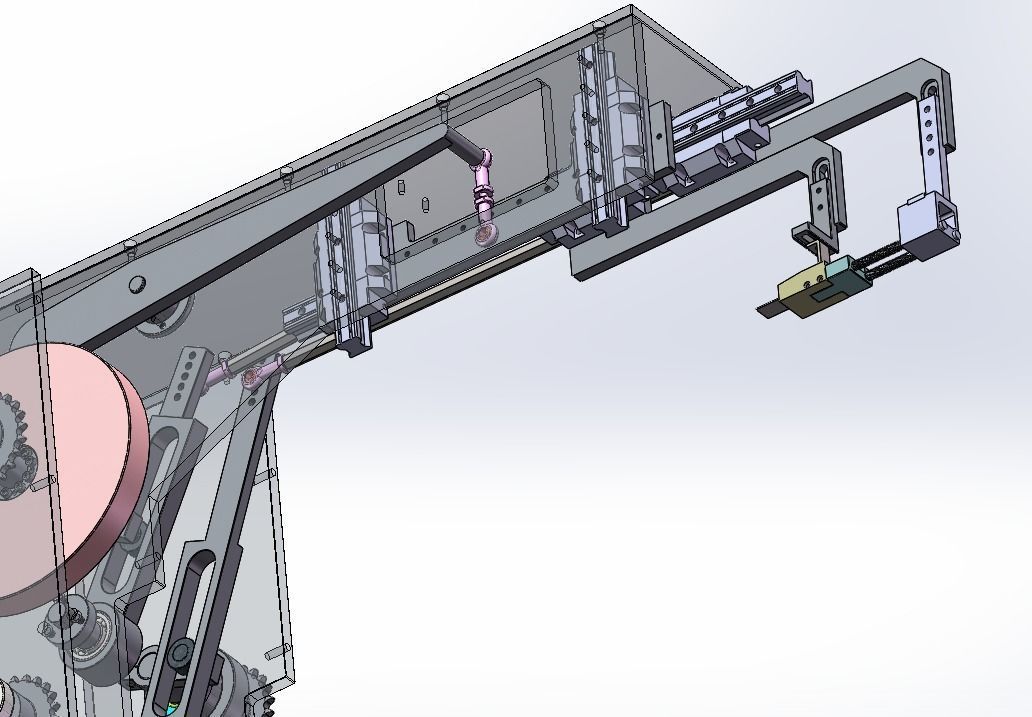

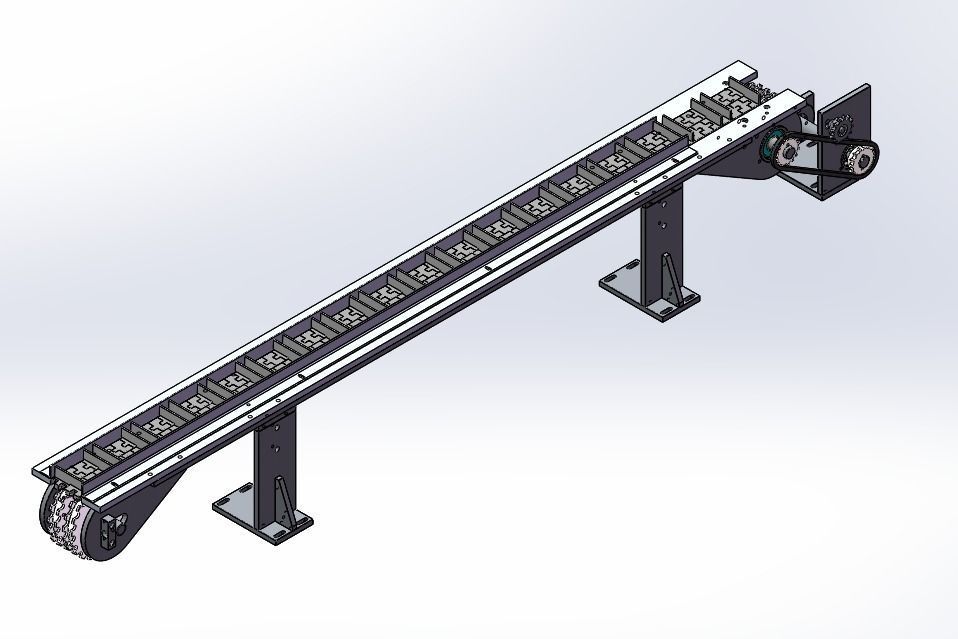

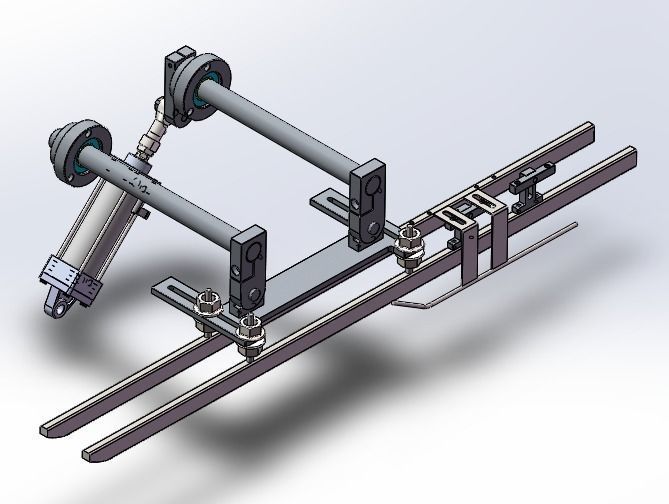

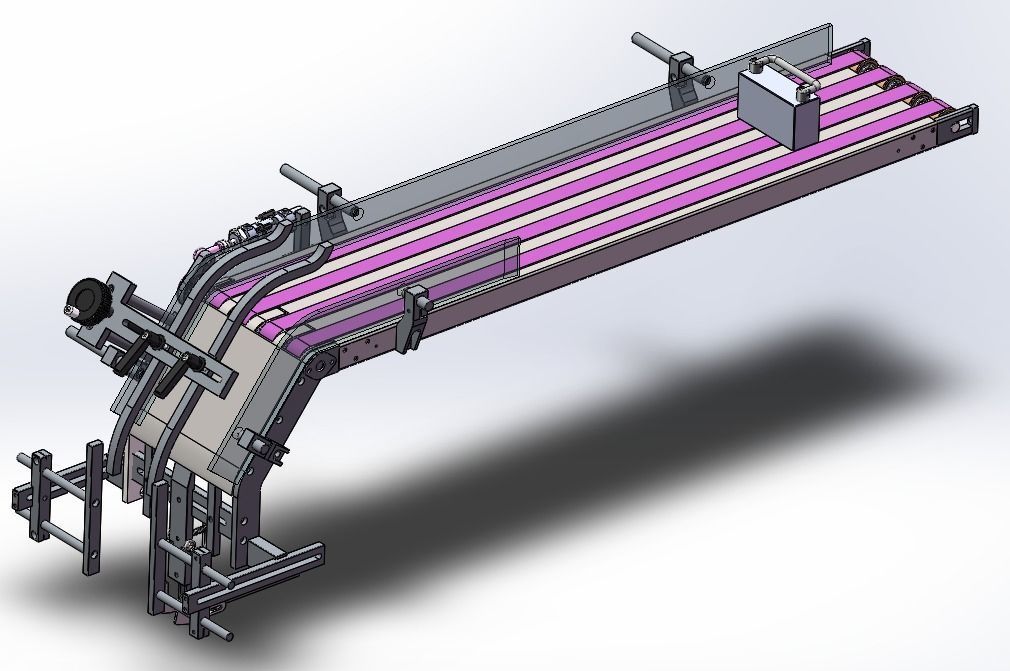

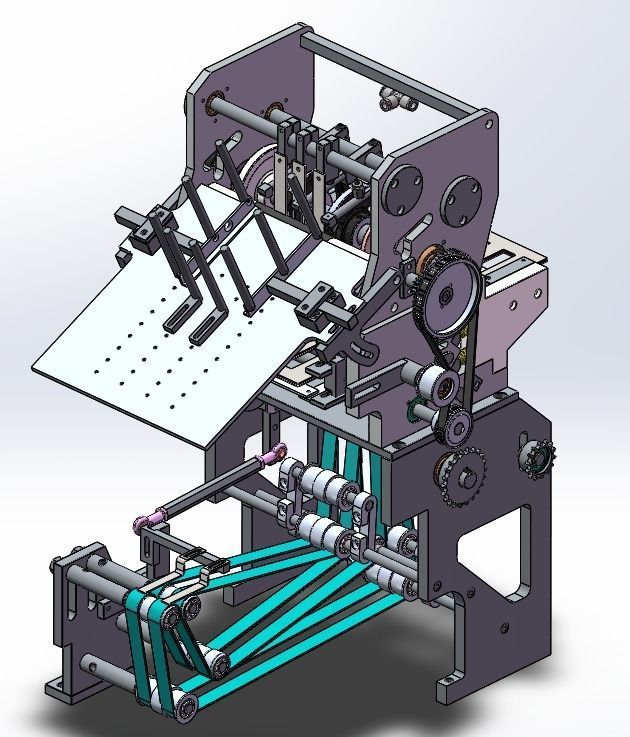

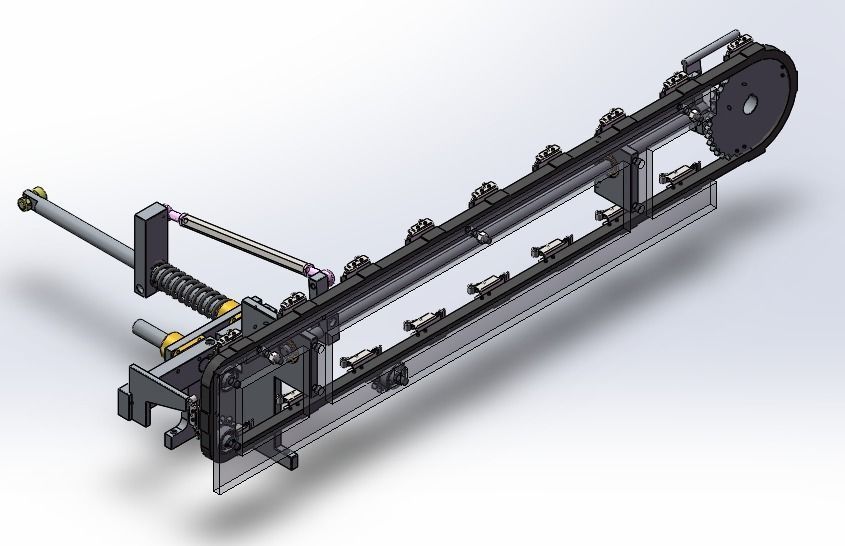

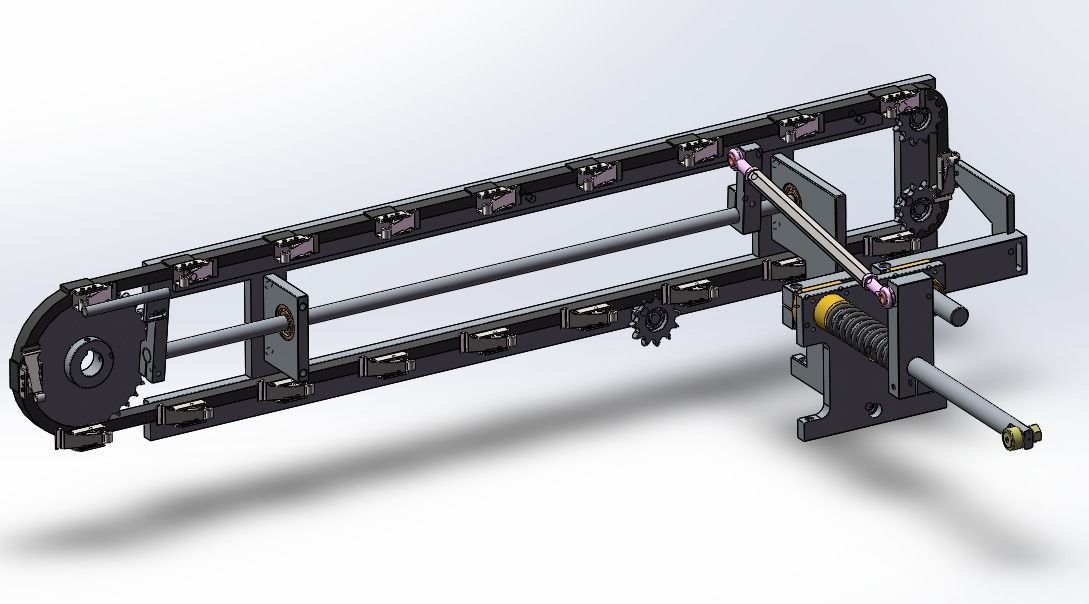

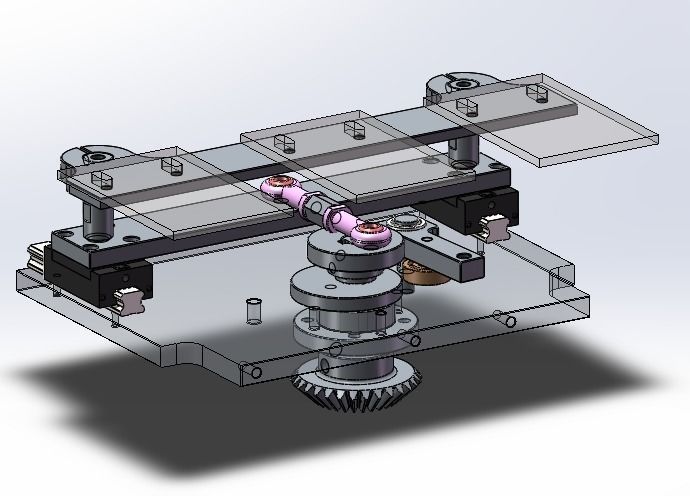

The automatic cartoning machine feed is generally divided into three entrances: the manual entrance, the medicine bottle entrance and the machine package box entrance. The whole process from the feeding of the machine package box to the final packaging forming can be roughly divided into four stages: the carton is fixed by a guide rail and a push plate is used to open the carton. At the same time, there will be two moving forwards from Raise the bottom, jam the side of the carton from the front and back, make the box open at a right angle and move forward to the loading area. After filling in the filling area, the mechanism of the machine will fold the ears into the left and right guide rails, and then perform the closing action. The pre-closing mechanism will first bend the tongue of the box, and then a push plate pushes the box cover to bend, so that the tongue is inserted into the box and the lock is fastened. The closing action is a critical action, and the quality of completion has a lot to do with the structure of the carton and the accuracy of the machine adjustment. Full-automatic high-speed cartoning machine drawings (full cam type), there are 2 motors to achieve dozens of action cycles, manuals, and products are automatically packed into the box together: including solidworks2015 STP XT format, including parts drawing, part assembly drawing, general assembly drawing More than 1400 parts and components. This product is suitable for boxing and packaging of pharmaceutical aluminum-plastic plates, round bottles, heterosexual bottles, cosmetics, auto parts, toothpaste, office supplies, poker, etc. and similar items. It can automatically open the carton and pack the items. Boxes, sealing boxes, etc. work. This machine uses PLC to control the photoelectricity to monitor the action of each part. It automatically rejects unqualified items during operation. If there is an abnormality, it can automatically stop and display the reason for troubleshooting in time. The machine can be used alone or combined with a blister packaging machine. The hot melt device or other equipment is used in conjunction to form a complete production line. Main performance and structural features: 1. It adopts automatic opening (suction) box, folding instructions, blanking, feeding, batch numbering, box sealing, waste detection and other processes, smooth operation and low noise. 2. Using PLC and man-machine interface to automatically control the operating system, stepless variable frequency speed regulation, high degree of automation, easy to understand and easy to operate. 3. Adopt international famous brand electrical components, stable and reliable performance. 4. The automatic shutdown function of mechanical overload is adopted to ensure the safety of man and machine. 5. Automatically reject packaged products that lack packaging or instructions to ensure the quality of packaged products. 6. It has functions such as fault display, alarm and finished product count, which is convenient for maintenance and troubleshooting. 7. Various automatic feeders and conveying mechanisms can be designed according to customer requirements. 8. Optional hot melt glue machine adopts hot melt glue spray glue seal or design hot melt glue brushing device. 9. It can be used with aluminum-plastic packaging machine, pillow packaging machine, filling machine, soap making machine, inkjet printer (or supervisory code system), labeling machine, online weighing machine, three-dimensional packaging machine, heat shrink packaging machine, Belt strapping machine, other production lines, etc. realize butt joint production. Main technical parameters Power supply: Ac380 volt three-phase five-wire system power supply 50 Hz total power 2.5 kilowatts production capacity host operating speed: 50-120 boxes/minute air consumption: 20 cubic meters/hour (pressure 0.5-0.8 MPa) weight: approximately 1.2 tons