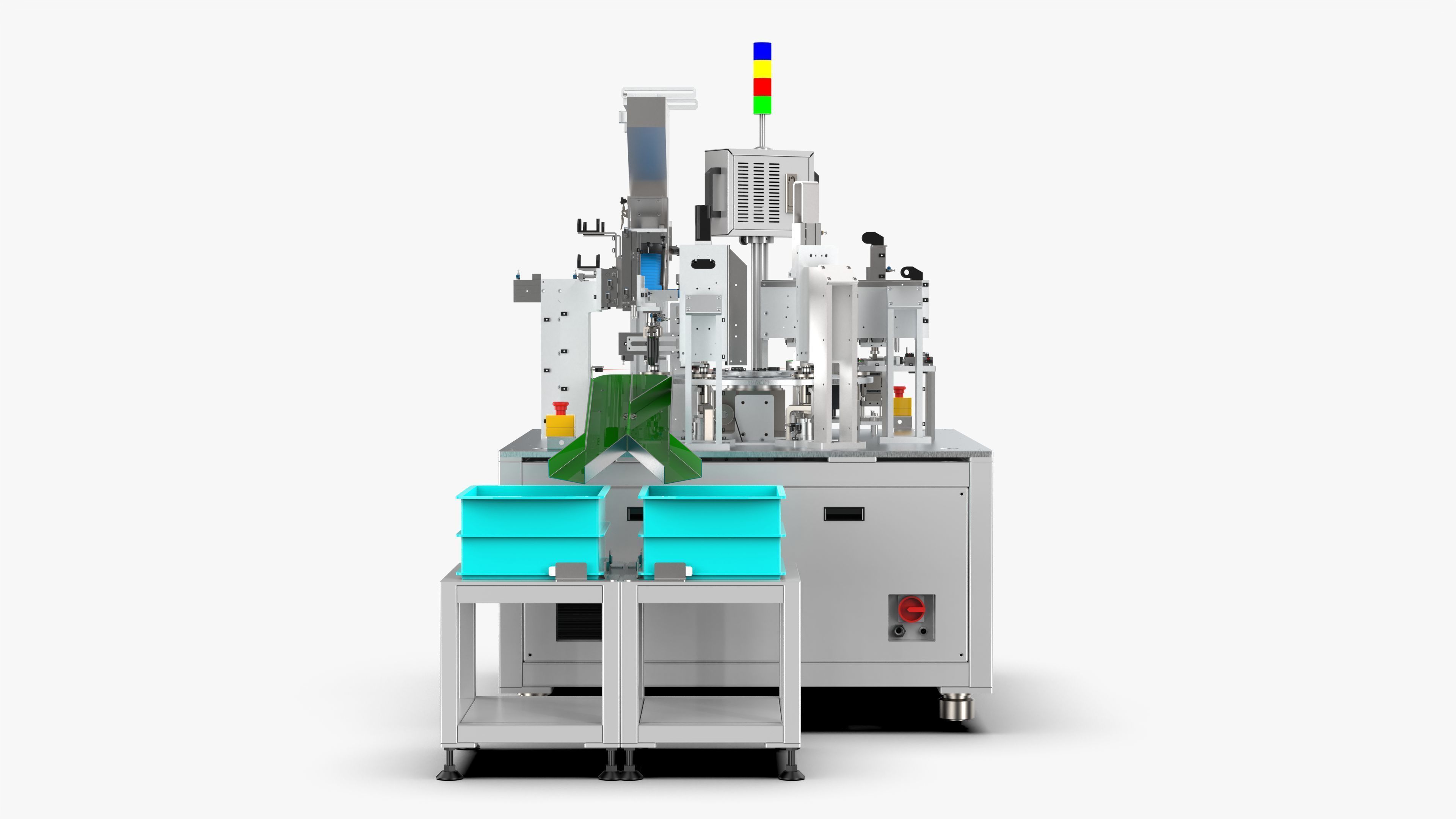

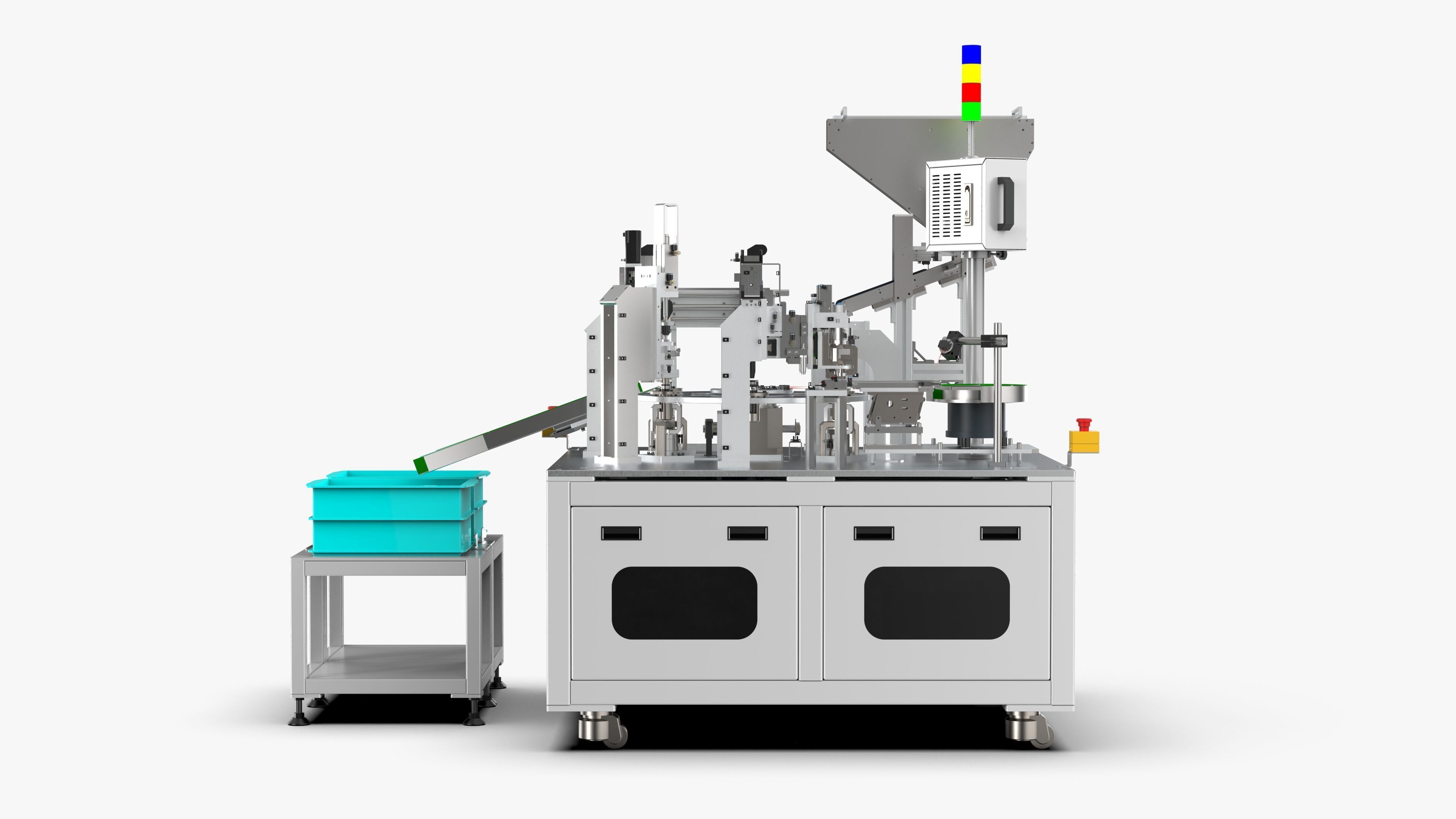

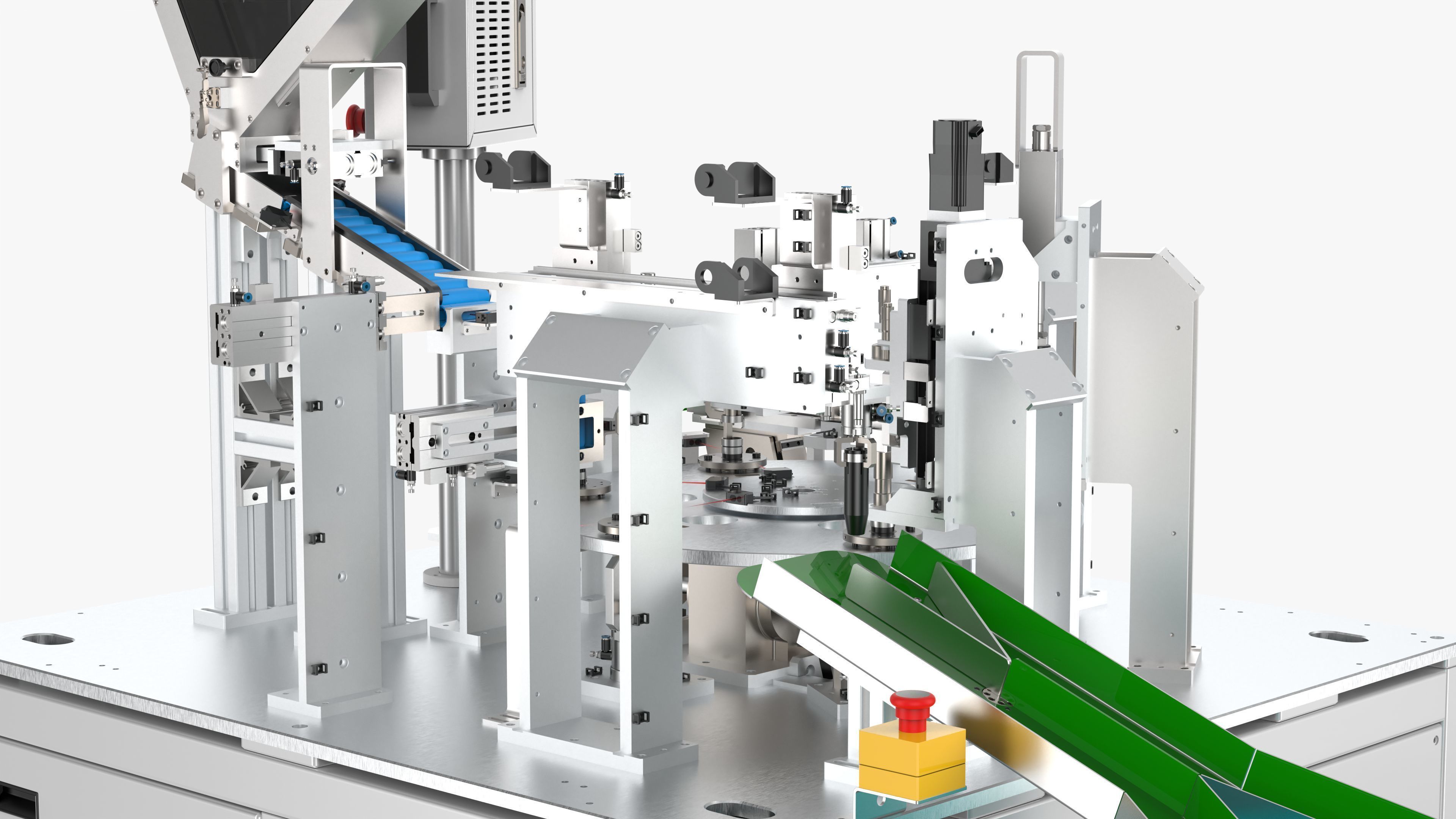

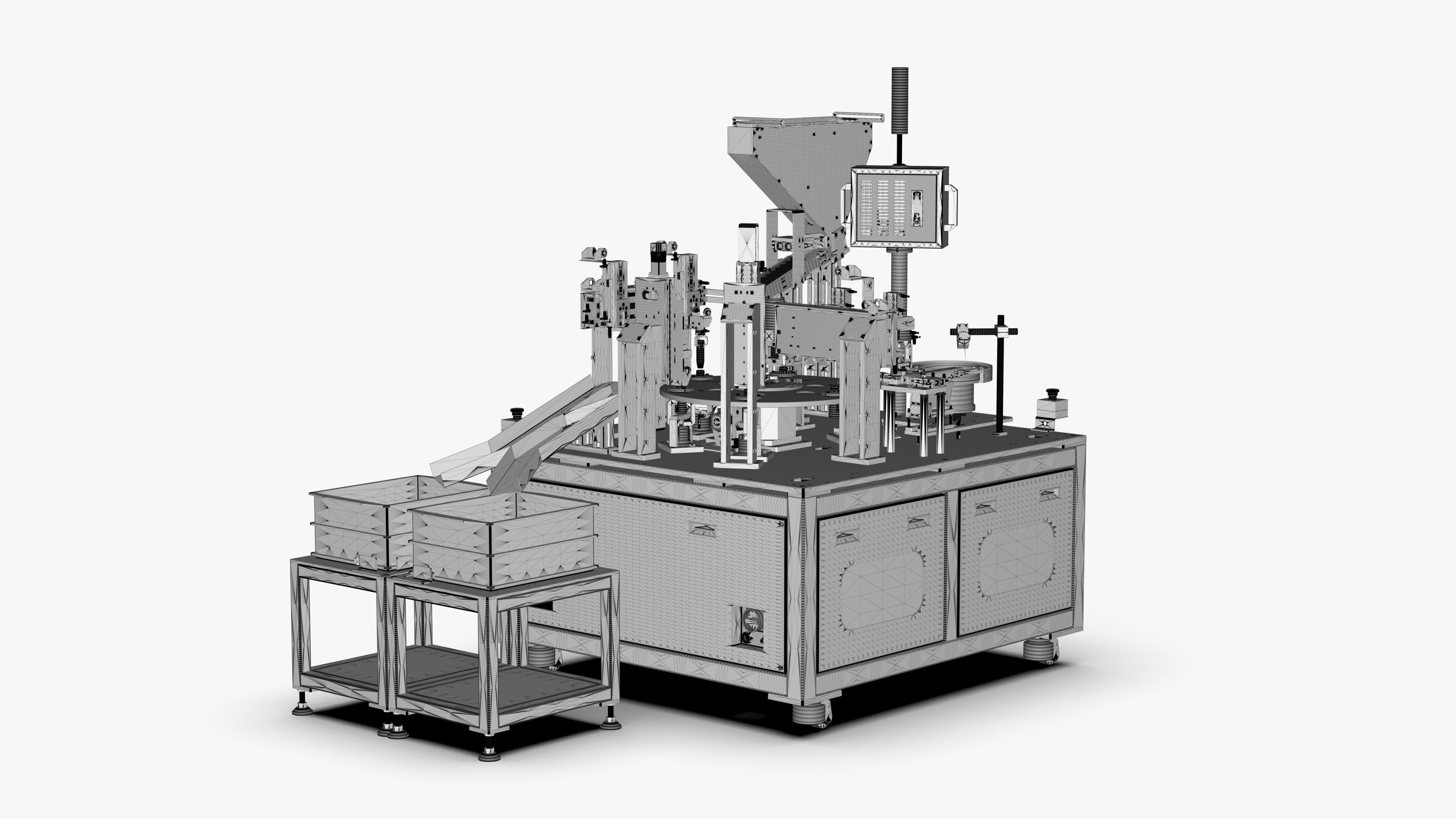

Automatic Circlip Assembly Machine 3D model

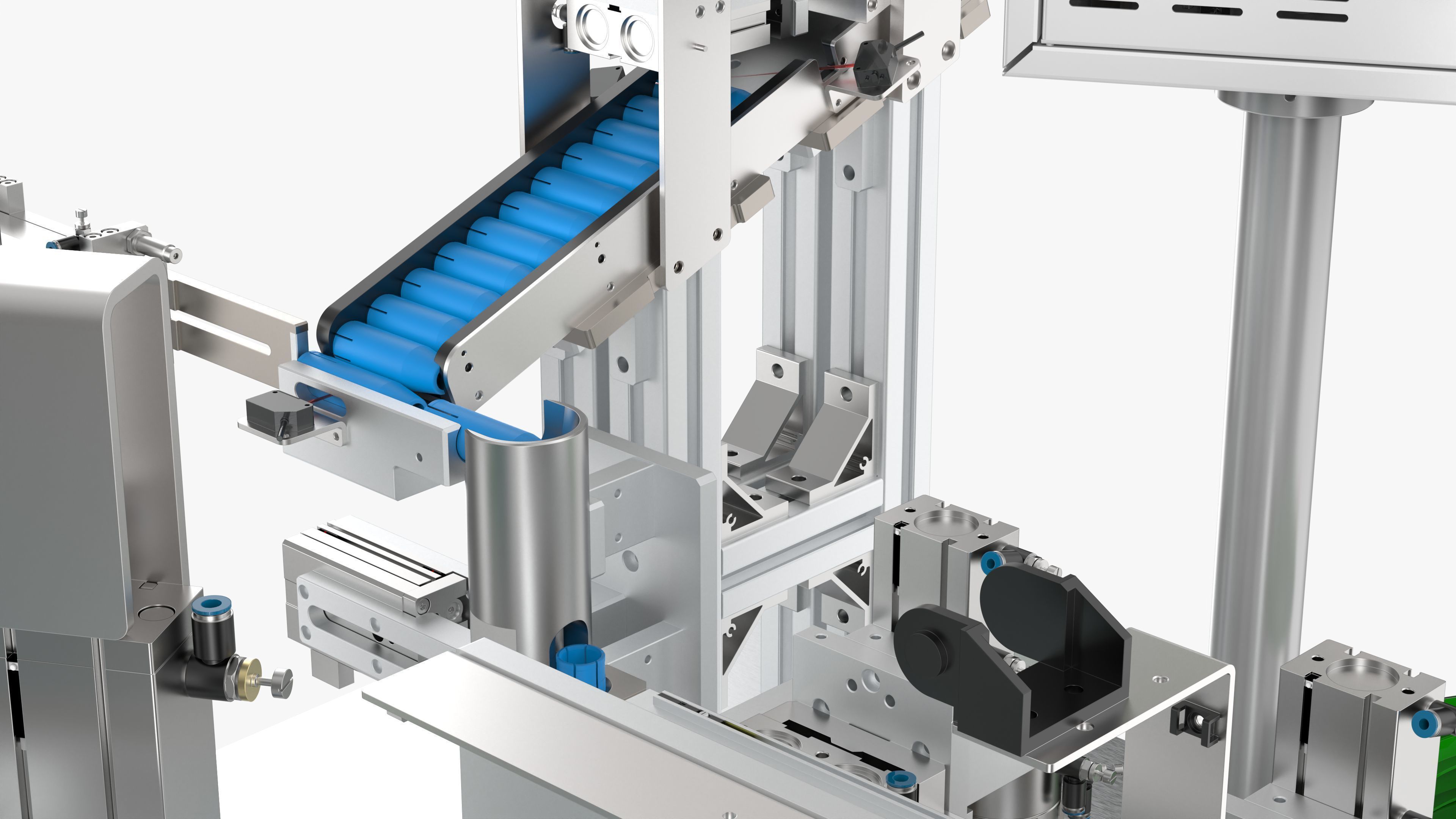

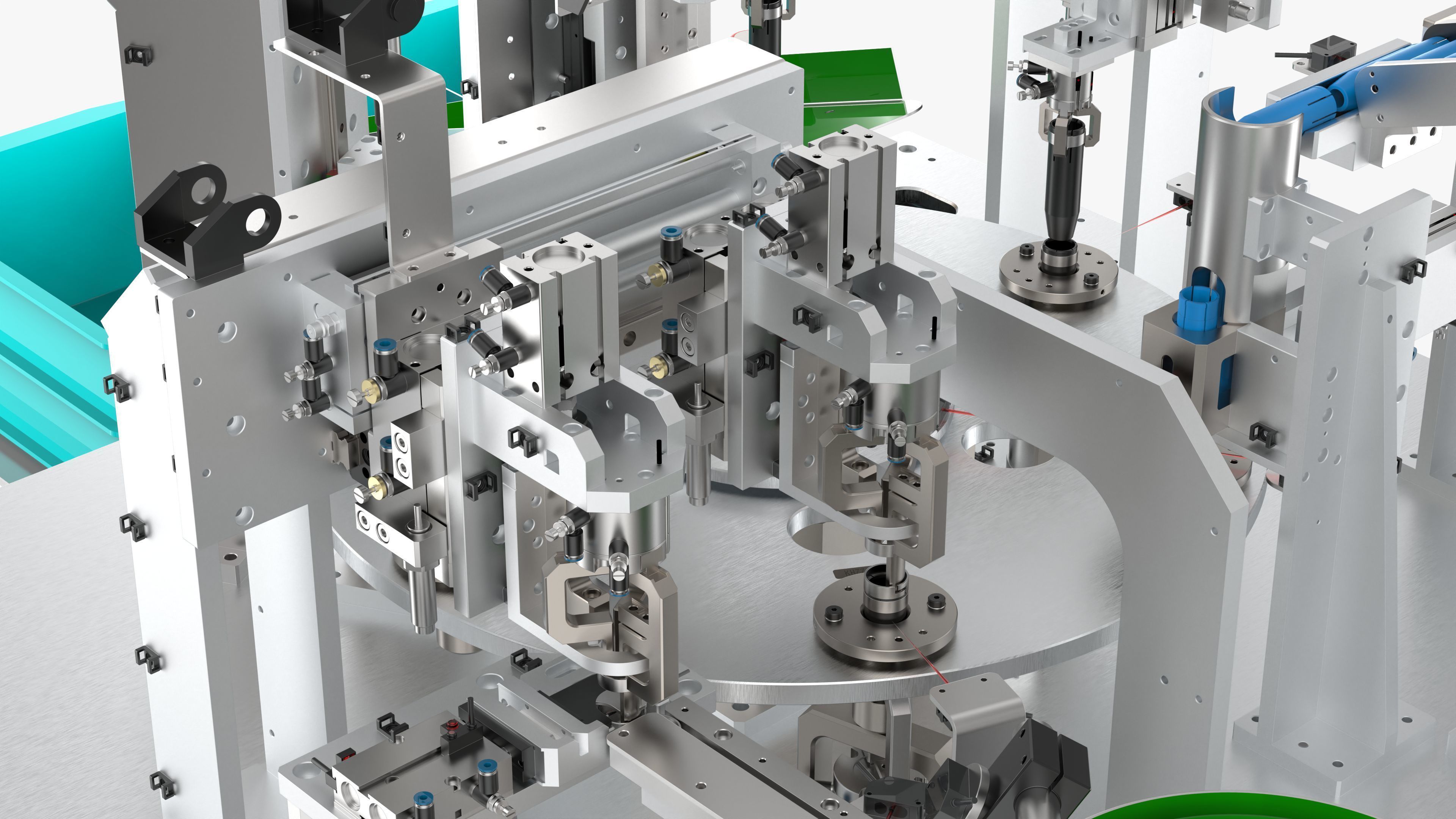

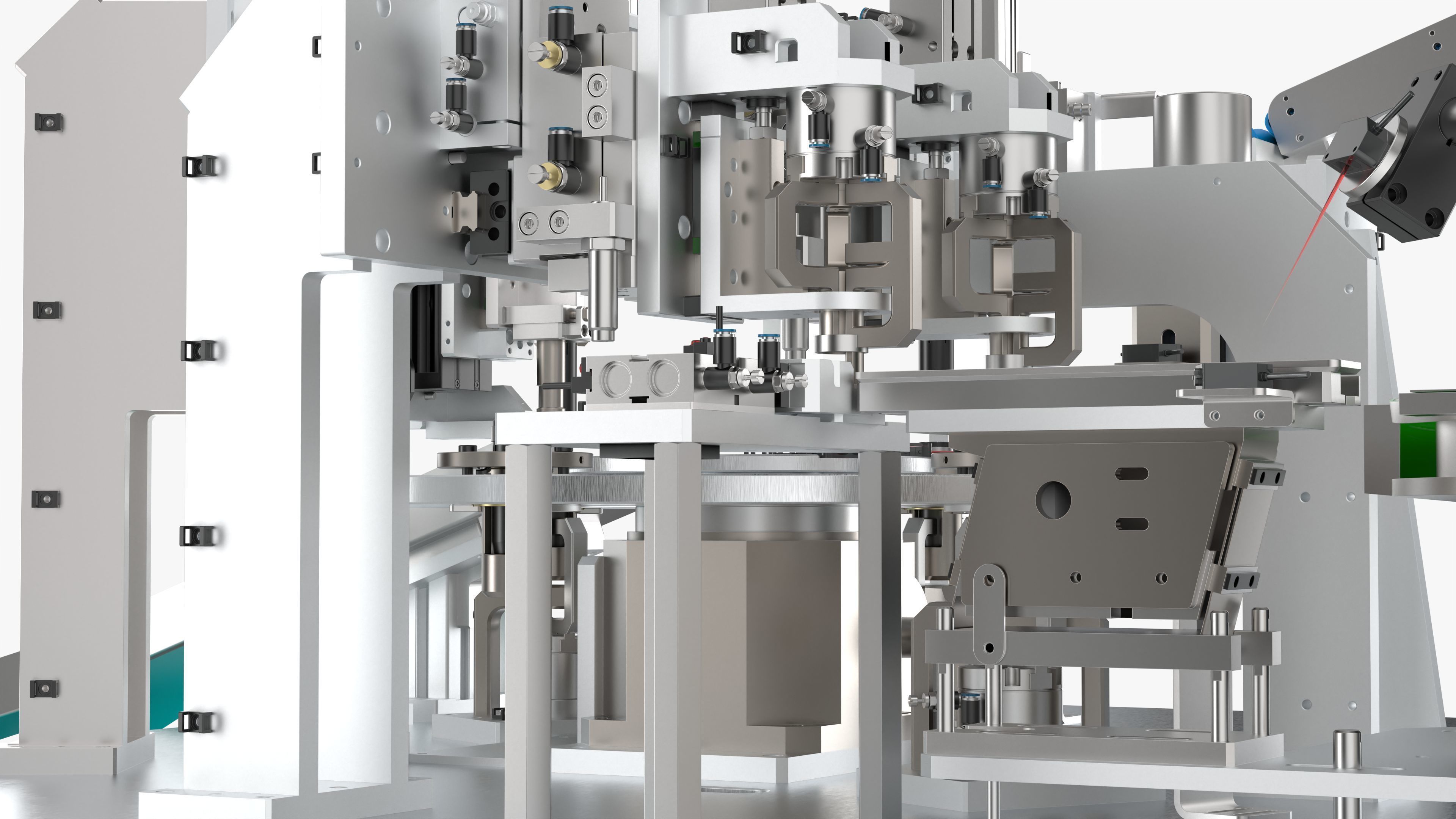

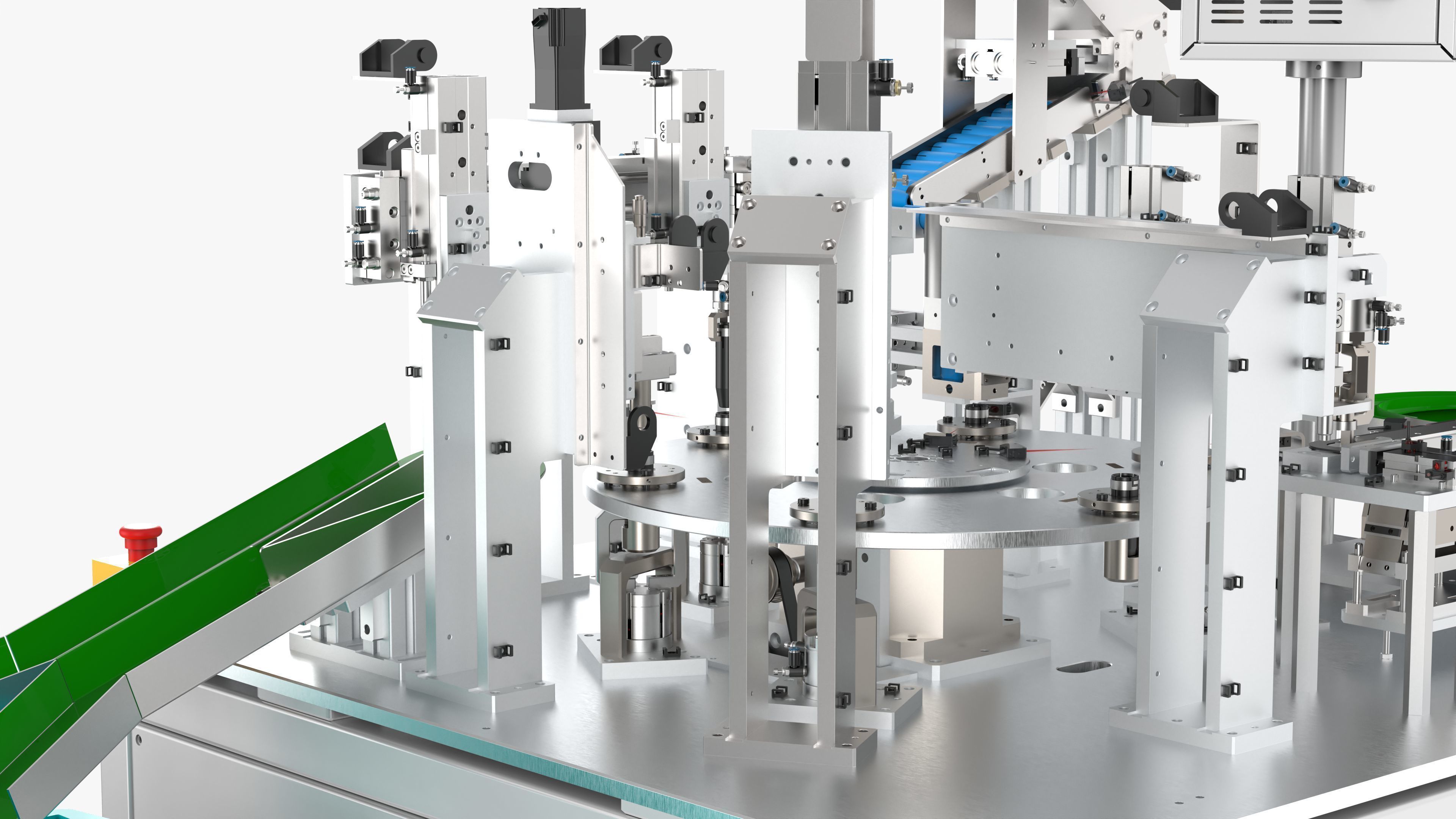

Automatic Circlip Assembly Machine

Introduction

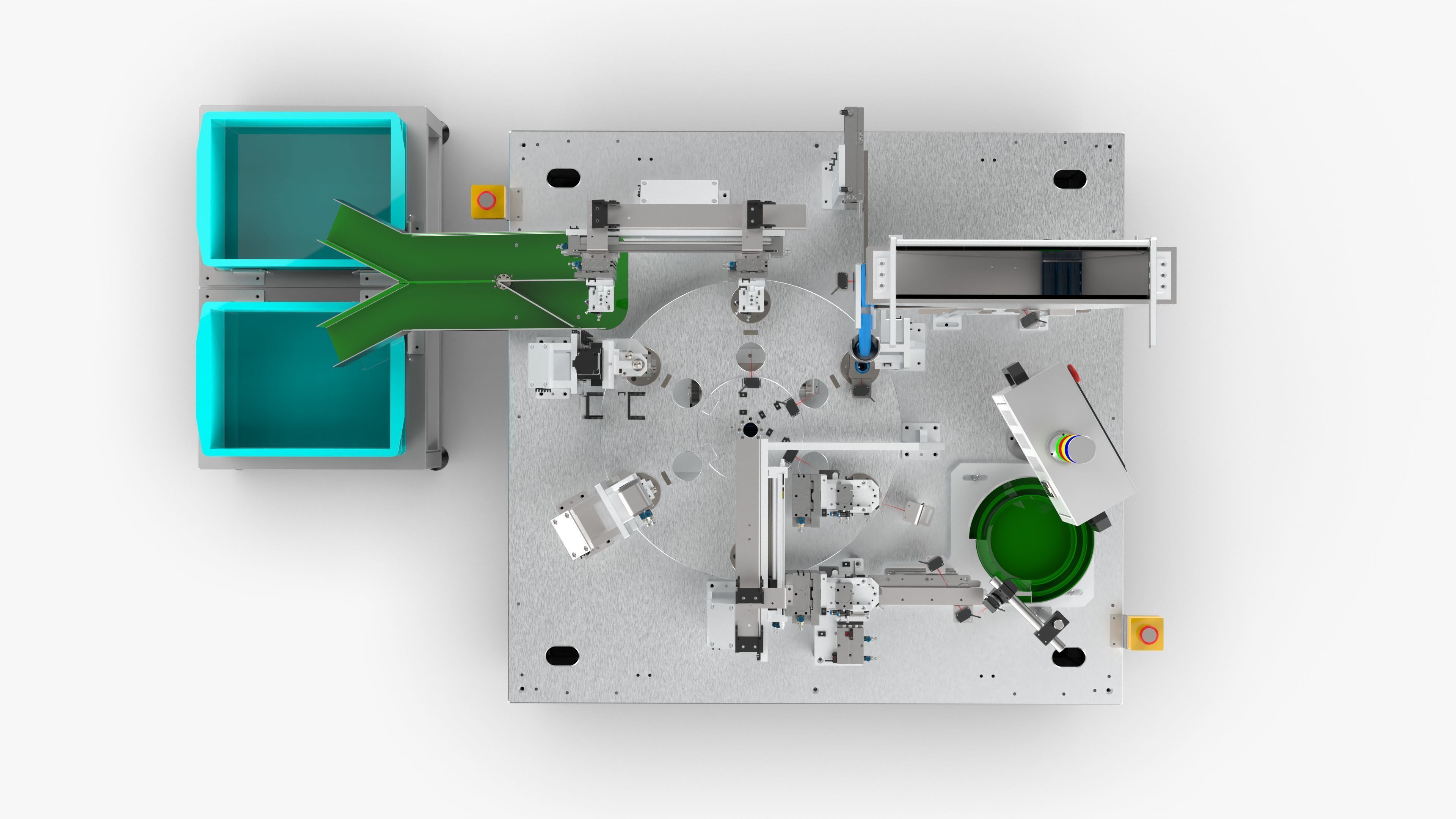

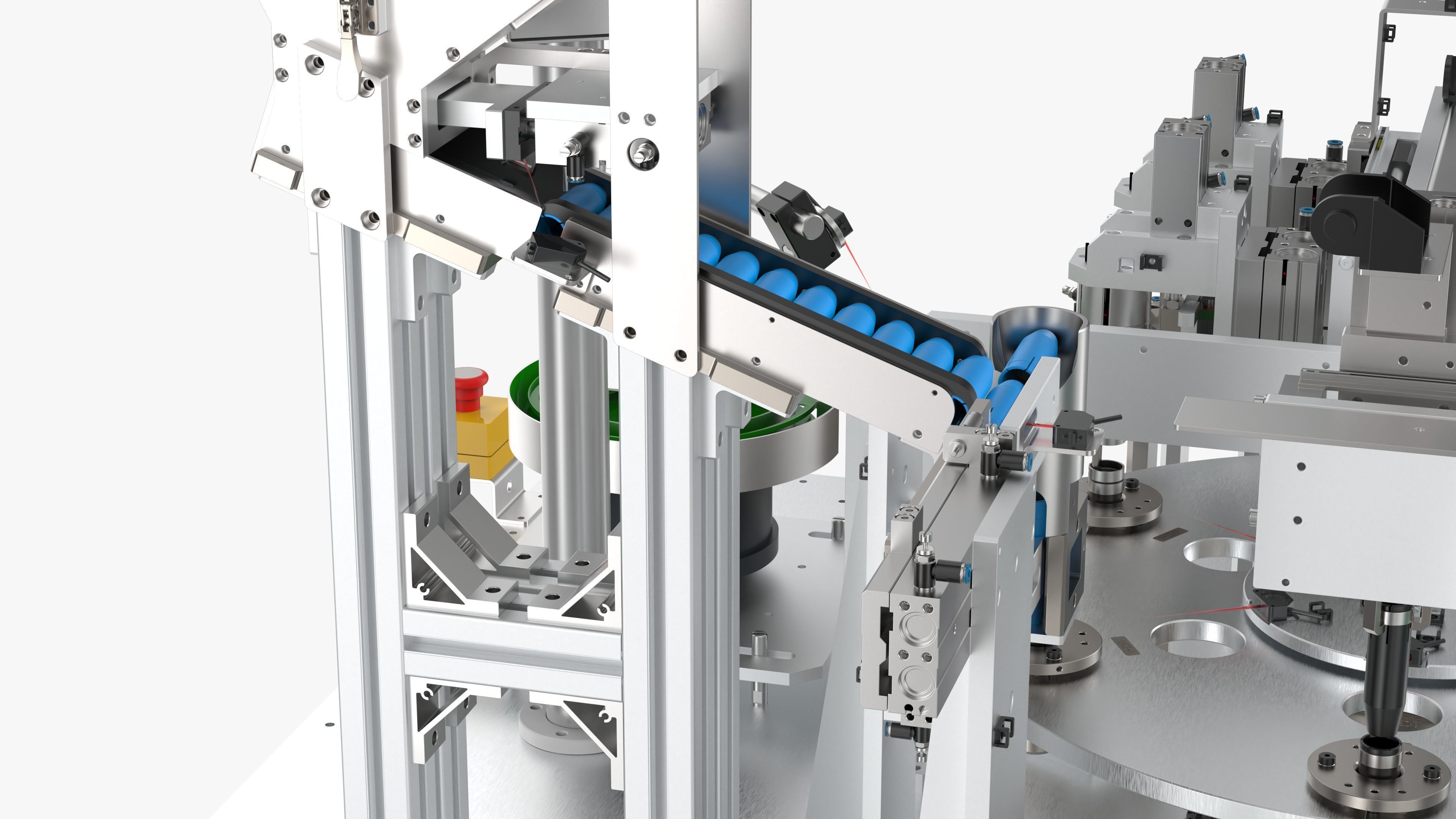

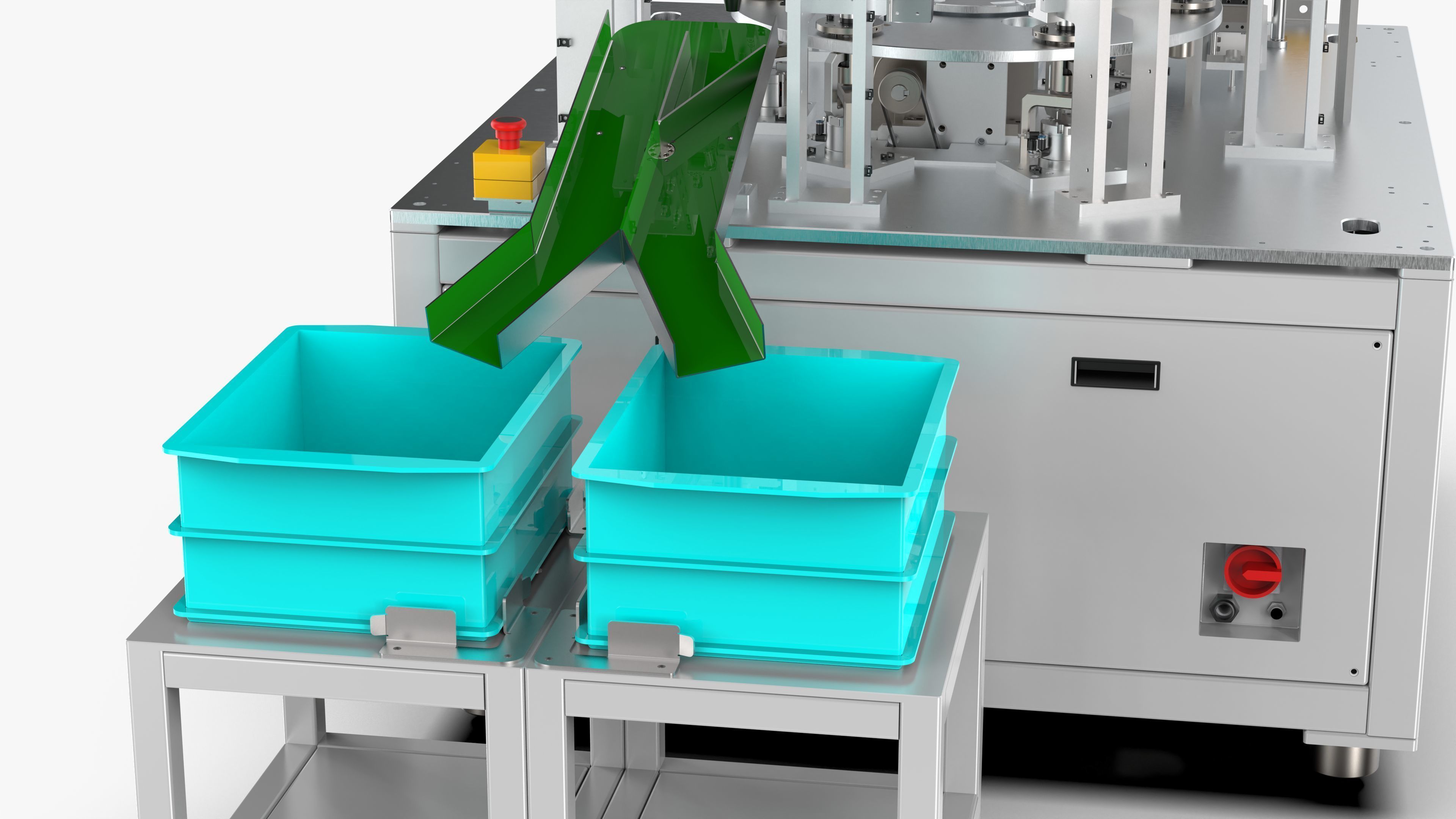

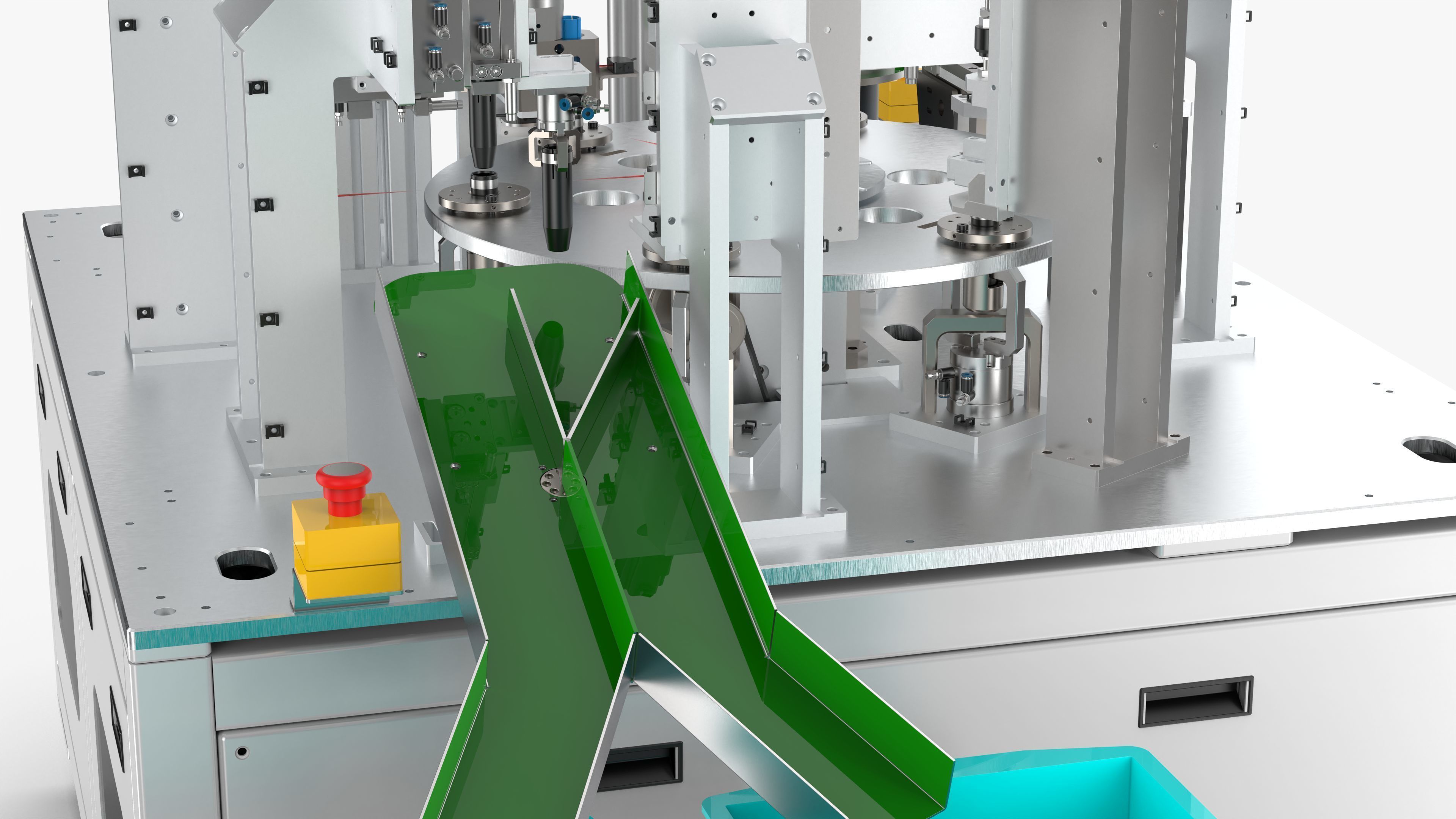

The circlip automatic assembly machine is to place the copper tube into the V-shaped material box with the help of manual labor, and place the circlip into the circular vibrating plate with the manual assistance. The transfer of the copper tube and the circlip, Assembly, testing, and sorting are automated through mechanisms, thereby saving labor, improving efficiency, and reducing the production line footprint. The copper pipes are fed to the chute through the V-shaped hopper, and the cylinder pushes and drops the front-end copper pipes arranged in the chute to the copper pipe feeding jig of the rotating disk; the rotating disk rotates 60°, and the circlip passes through the circular vibration , The direct vibration is arranged in place, dislocated to the second position, the three-claw cylinder grabs, spreads, transfers, and inserts it on the copper tube of the second station (clamping and positioning by the air claws at the lower part of the copper tube), and presses in the circlip at the same time The mechanism runs downwards, sets the circlip on the air claw to the specified position of the copper tube, and the above mechanism resets; the rotating disk rotates 60°, and the assembled product passes through the third detection station to detect whether the circlip is missing on the copper tube; The disk rotates 60°, the product is assembled to the fourth station, the reaming jig is enlarged, the inner hole of the assembled copper pipe is adjusted, and the position of the circlip is pressed at the same time; the rotating disk is rotated 60°, the product is assembled to the fifth station, and the inspection The cylinder of the mechanism is pressed down, and through the pressure sensor, the pressure is transmitted to drive the go-no-go gauge for copper tube detection to measure the inner hole requirements of the copper tube, and the pressure value is output to determine whether the assembled inner hole of the copper tube is a good product or a defective product; the rotating disk rotates 60°, The product discharge mechanism takes out the products in the jig, the good products slide into the good product box, and the defective products, the chute baffle rotates, and the products are discharged into the defective product box.

File Formats

- SolidWorks 2018 | Keyshot 10

- STEP (Standard for the Exchange of Product Data)

- IGES (Initial Graphics Exchange Specification)

- STL (Standard Tessellation Language )

- OBJ (Object Files)

Geometry

- Polygons: 2,556,373

- Vertice: 7,669,119