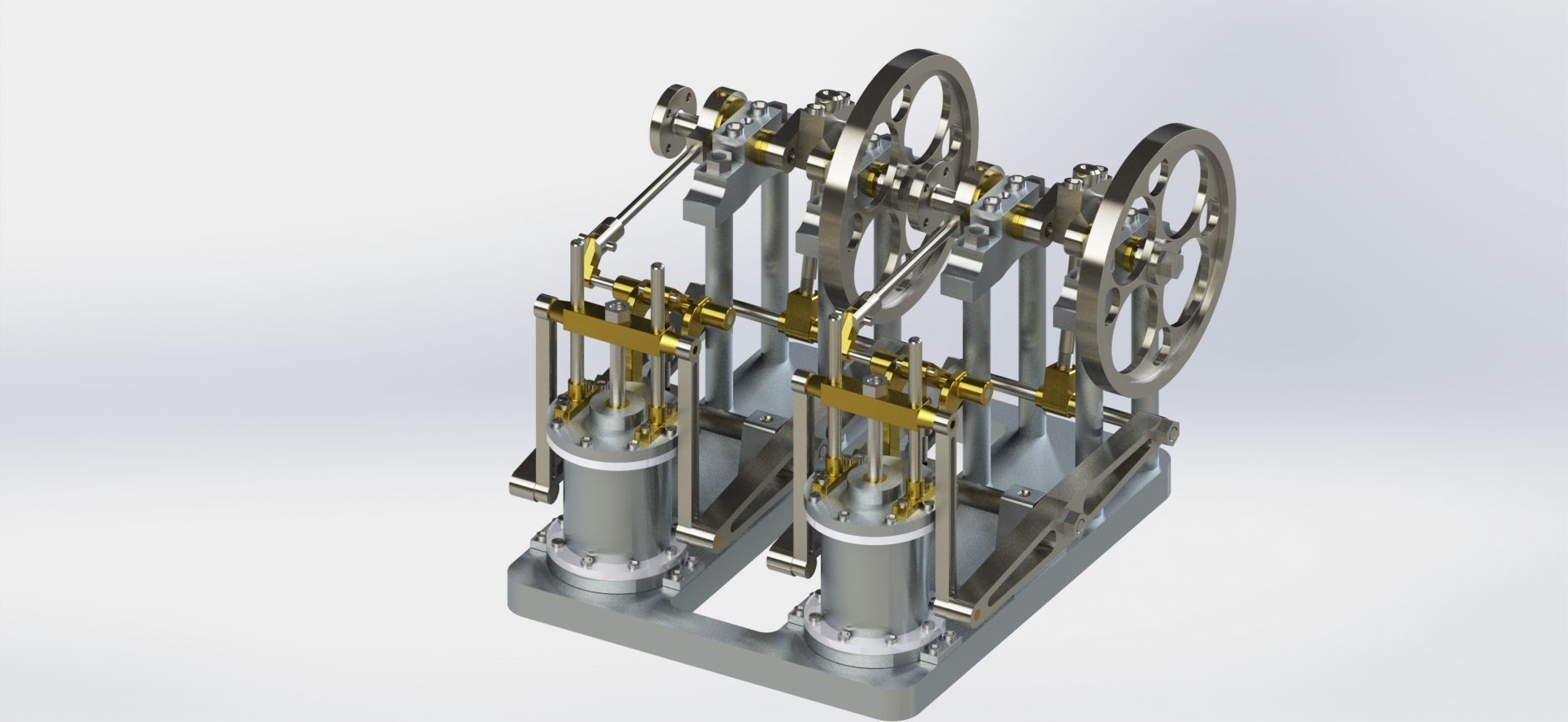

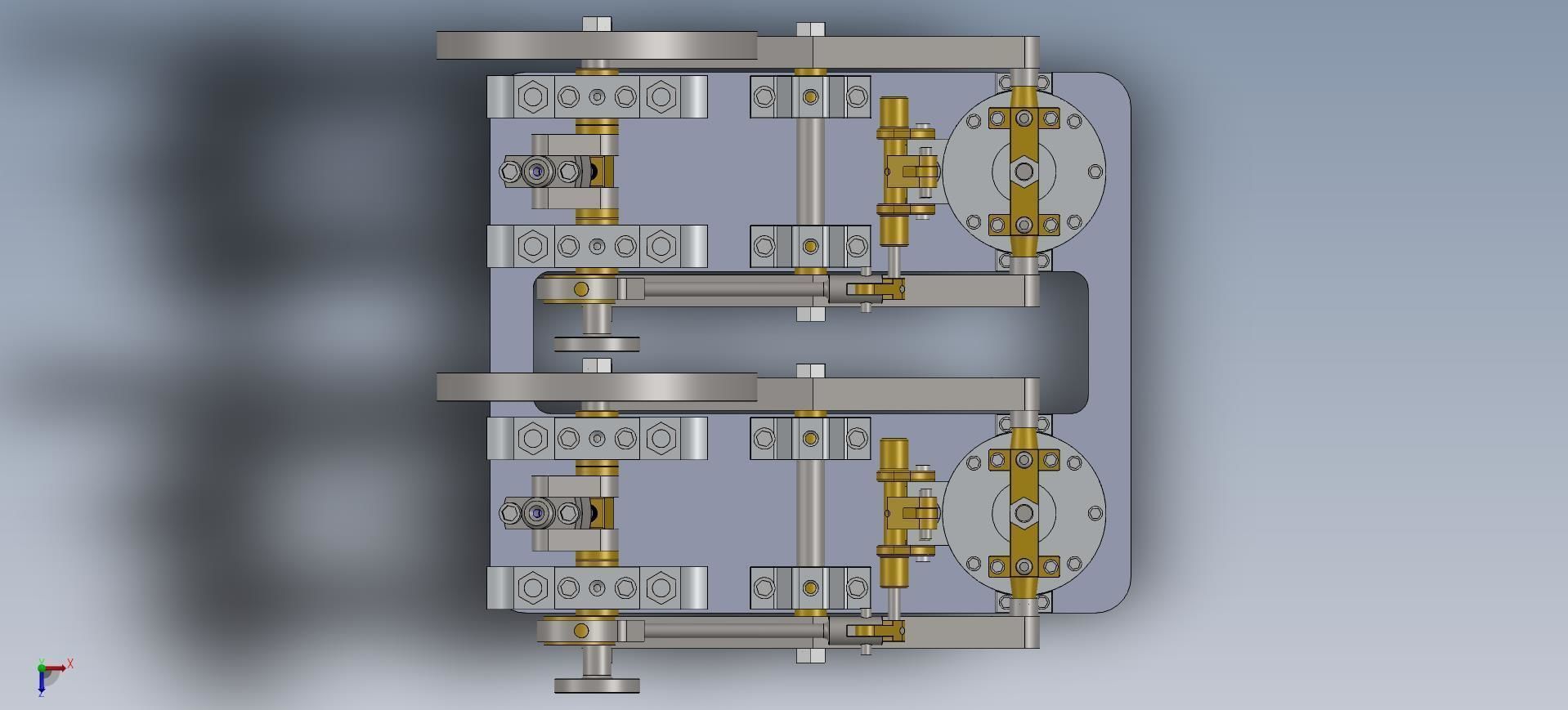

A TWIN CYLINDER SIDE BEAM STEAM ENGINE 3D model

A twin-cylinder side beam steam engine is a type of steam engine that features two cylinders and utilizes a side-mounted beam mechanism. This design is an advancement from the single-cylinder side beam engine and offers improved balance and power output. Here's an overview of its components and operation:

Components:

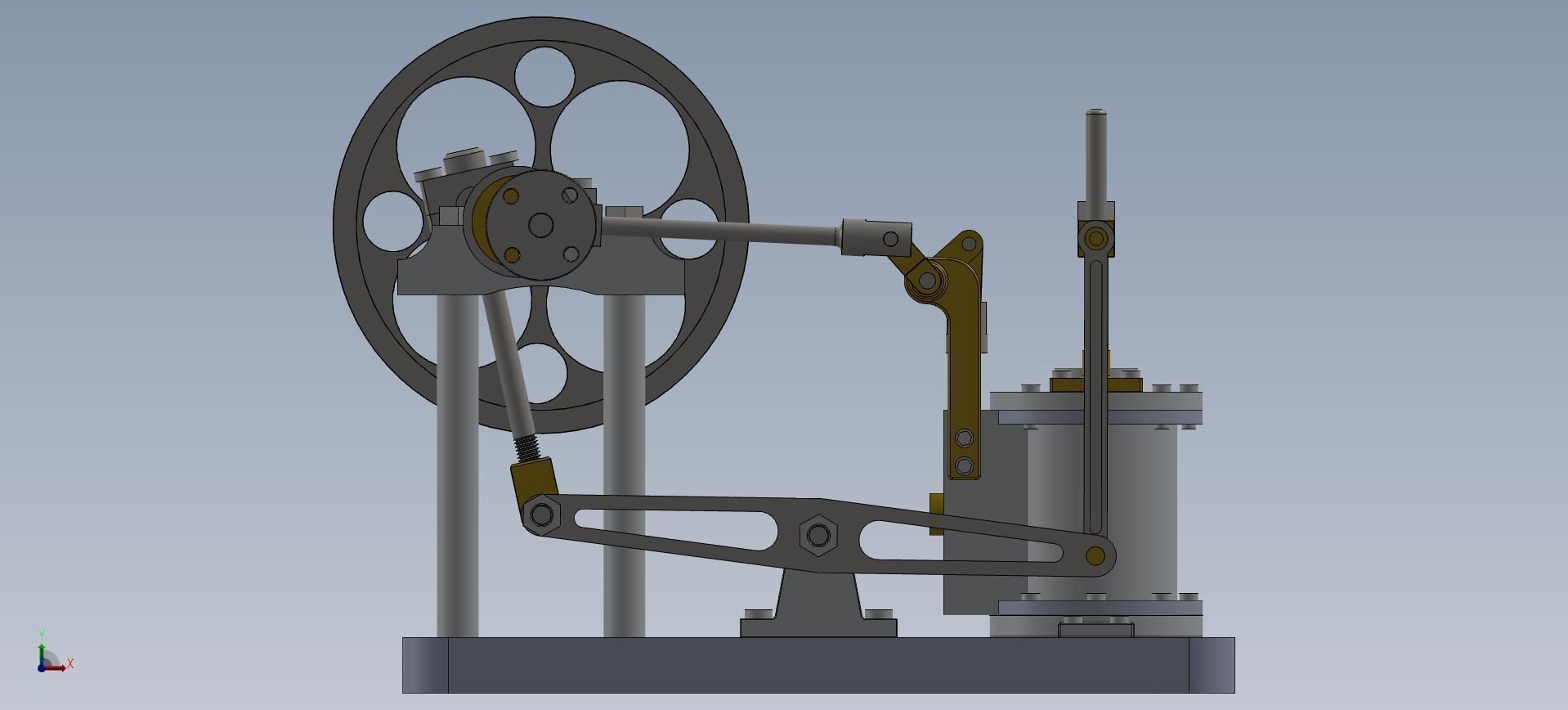

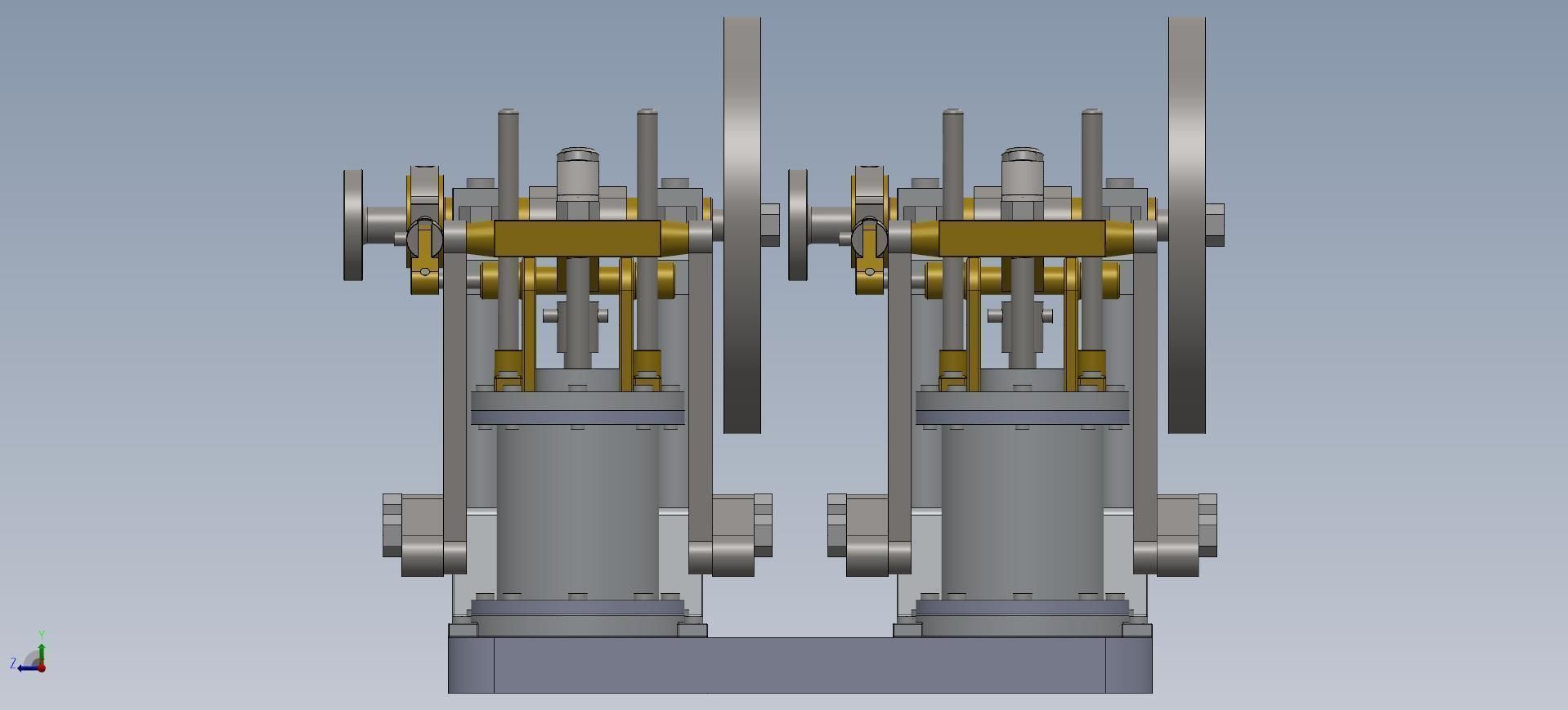

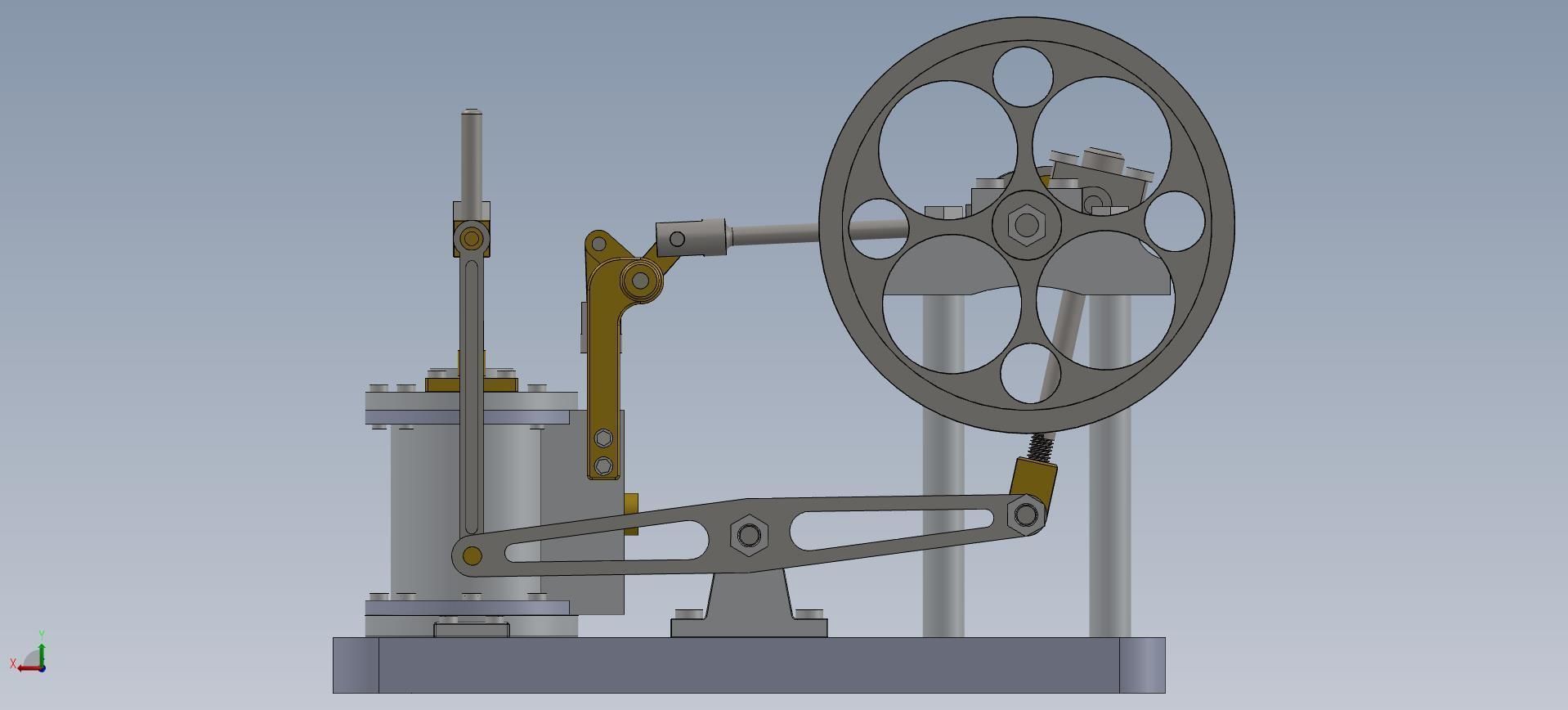

Cylinders: There are two cylinders arranged side by side or in a cross-like pattern.Pistons: Each cylinder contains a piston that moves back and forth within it.Crankshaft: The pistons are connected to a common crankshaft, which converts the reciprocating motion of the pistons into rotational motion.Connecting Rods: Connecting rods link the pistons to the crankshaft, transferring the motion of the pistons to the crankshaft.Side Beam Mechanism: A beam is attached to the connecting rods on both ends and connected to the crankshaft at the center. It transforms the vertical motion of the pistons into the rotational motion of the crankshaft.Working:

Steam Inlet: Steam is admitted into one end of each cylinder through a valve.Power Stroke: Steam enters one cylinder, pushing its piston away from the valve end. This is the power stroke. As the steam expands, it does work on the piston, converting its energy into motion.Exhaust: After the power stroke, a valve opens to allow the used steam to exit the cylinder.Piston Return: The side beam mechanism, along with the connecting rods, moves the piston back to its original position. This is the exhaust stroke.Steam Switch: Simultaneously, the other cylinder goes through a similar cycle. While one cylinder is in the power stroke, the other cylinder is in the exhaust stroke, and vice versa. This arrangement ensures a continuous rotational output.Advantages:

Balance: The twin-cylinder arrangement helps balance out the forces on the engine, reducing vibrations and providing smoother operation compared to single-cylinder engines.Increased Power: The presence of two cylinders allows for increased power output compared to single-cylinder designs.Disadvantages:

Complexity: The addition of a second cylinder and associated components adds complexity to the design, potentially affecting maintenance and potential failure points.Efficiency: While an improvement over single-cylinder engines, this design might still lack certain efficiency optimization features found in more advanced engines.Twin-cylinder side beam steam engines were used in various industrial applications during the Industrial Revolution. While they have been largely replaced by more advanced technologies today, they remain an important part of engineering history. If you're interested in learning more or working with such an engine, studying historical references and engineering principles will provide you with valuable insights.