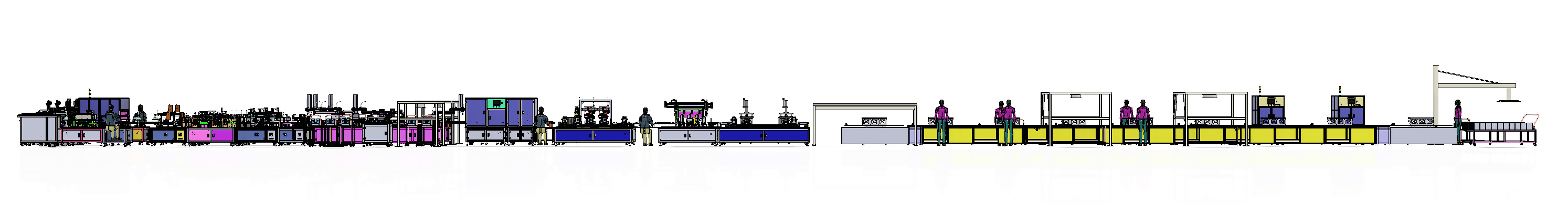

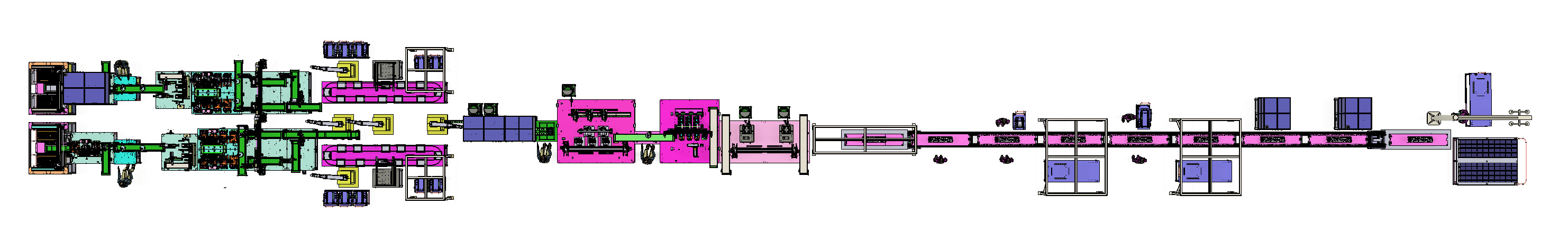

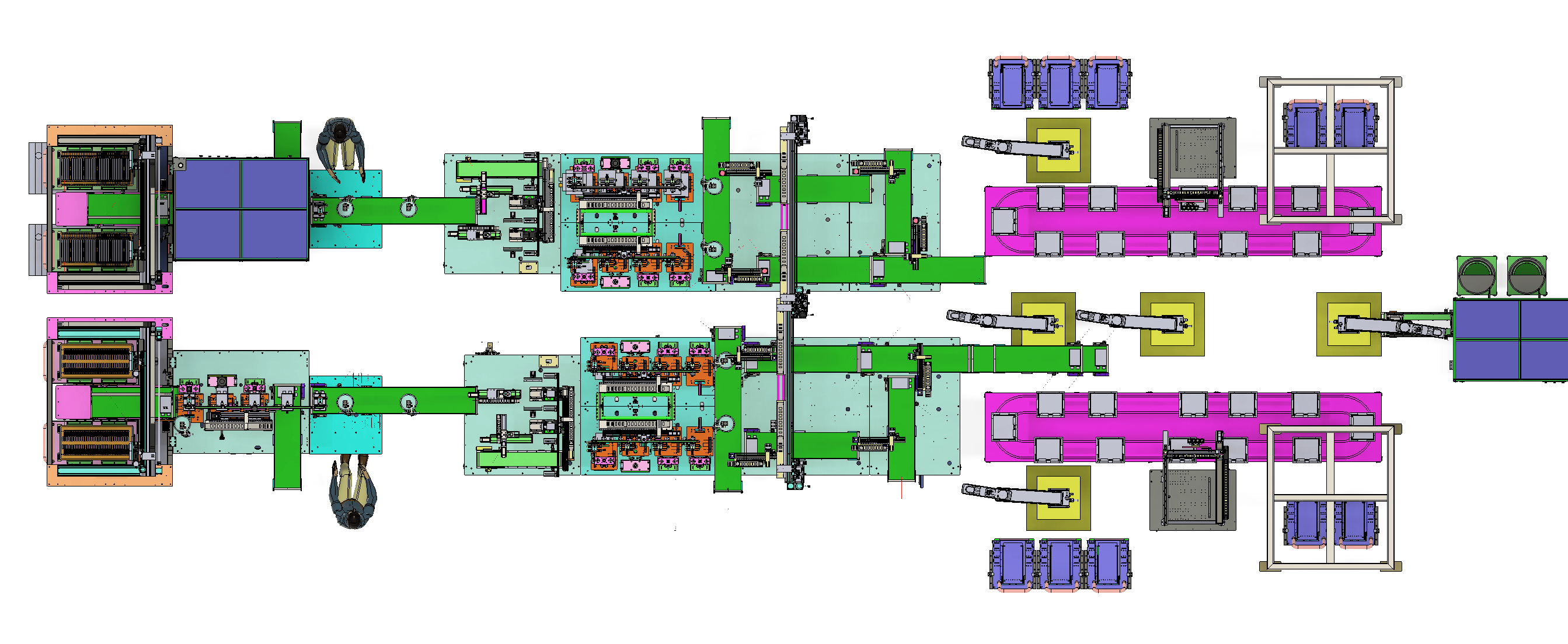

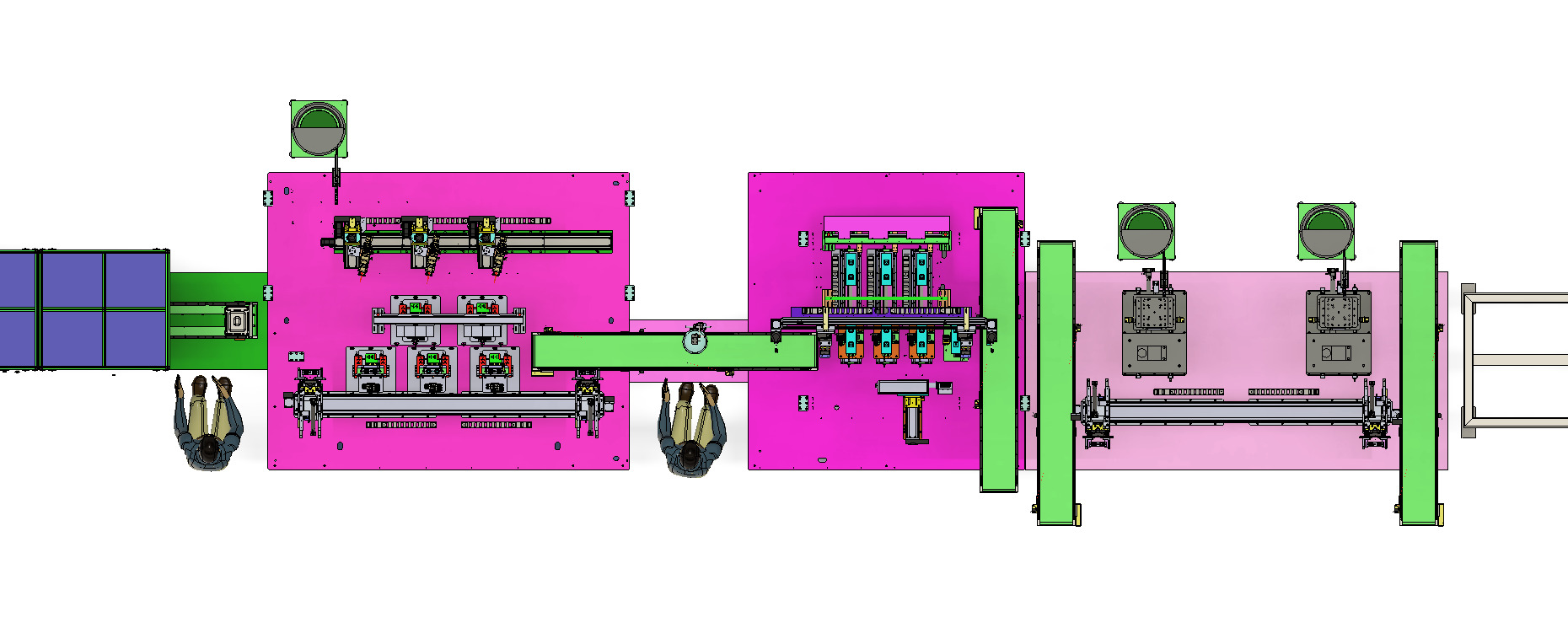

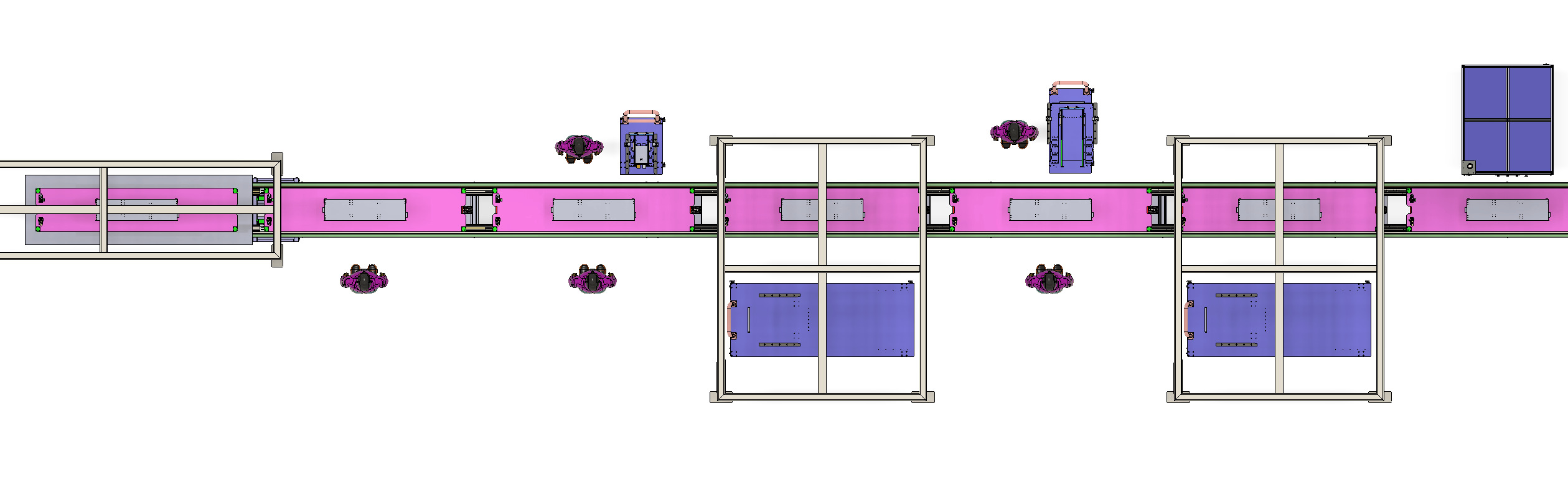

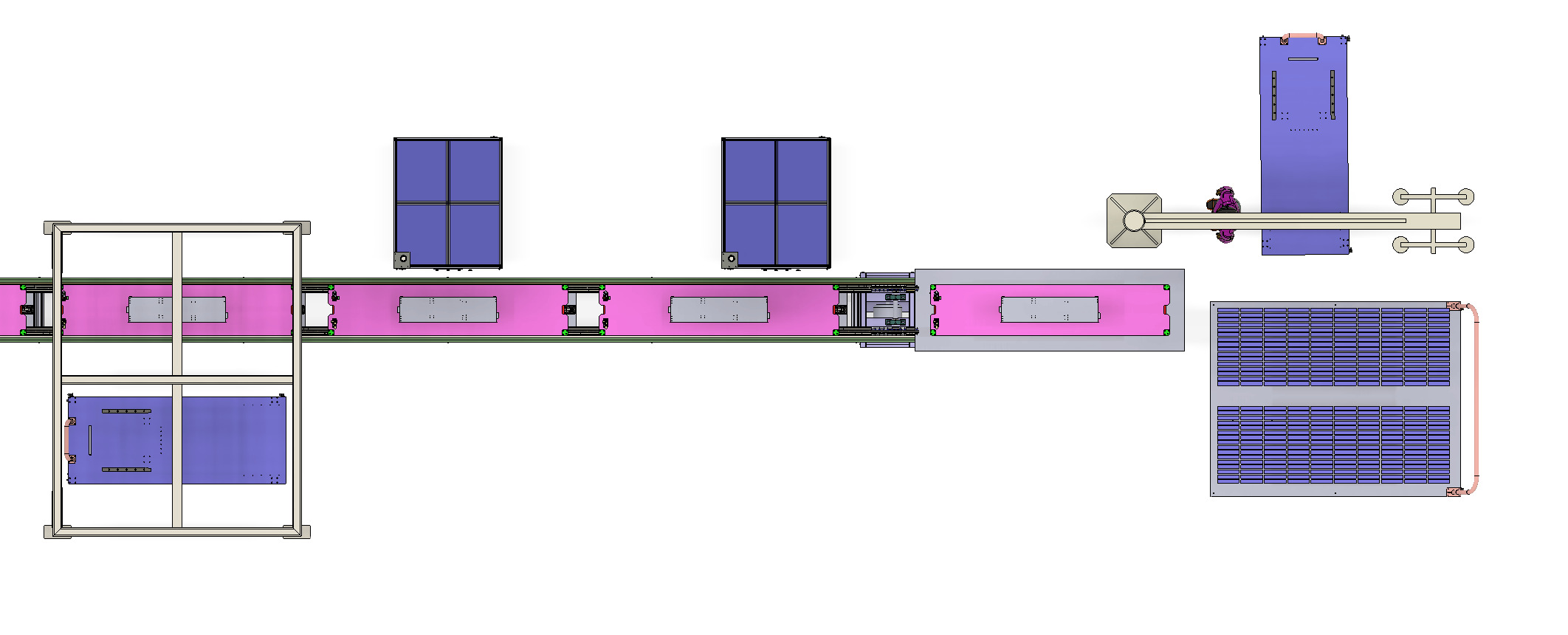

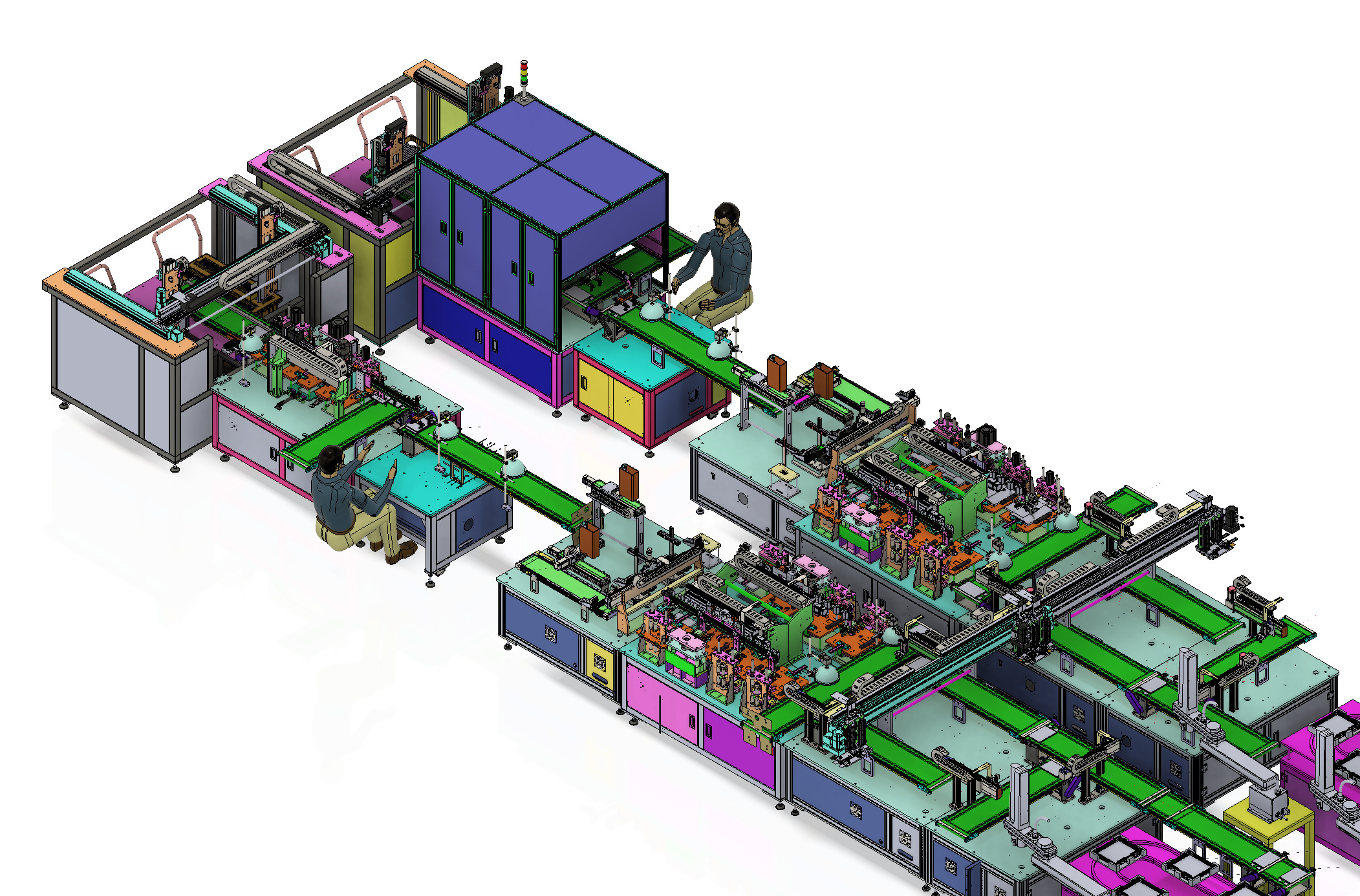

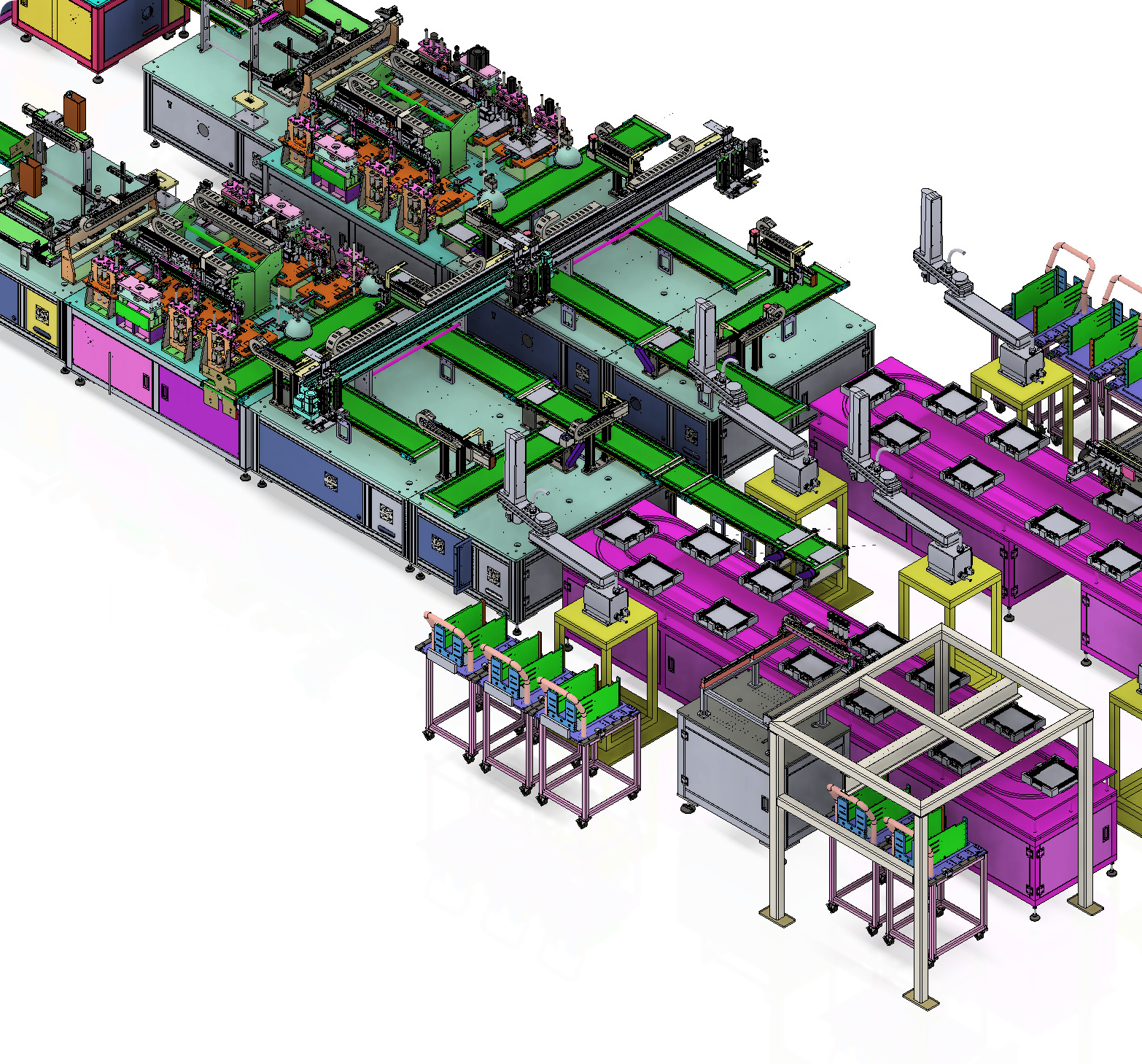

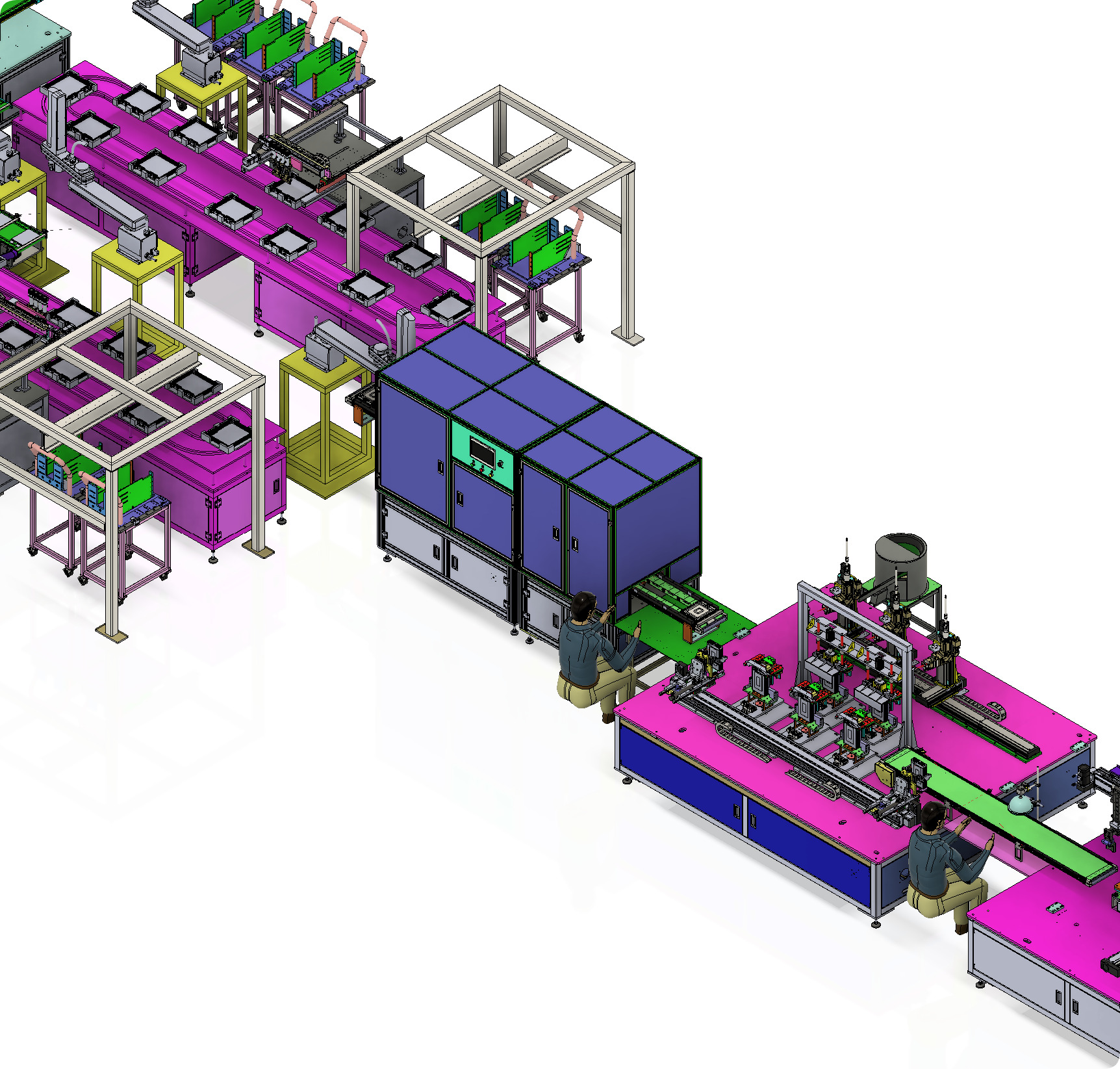

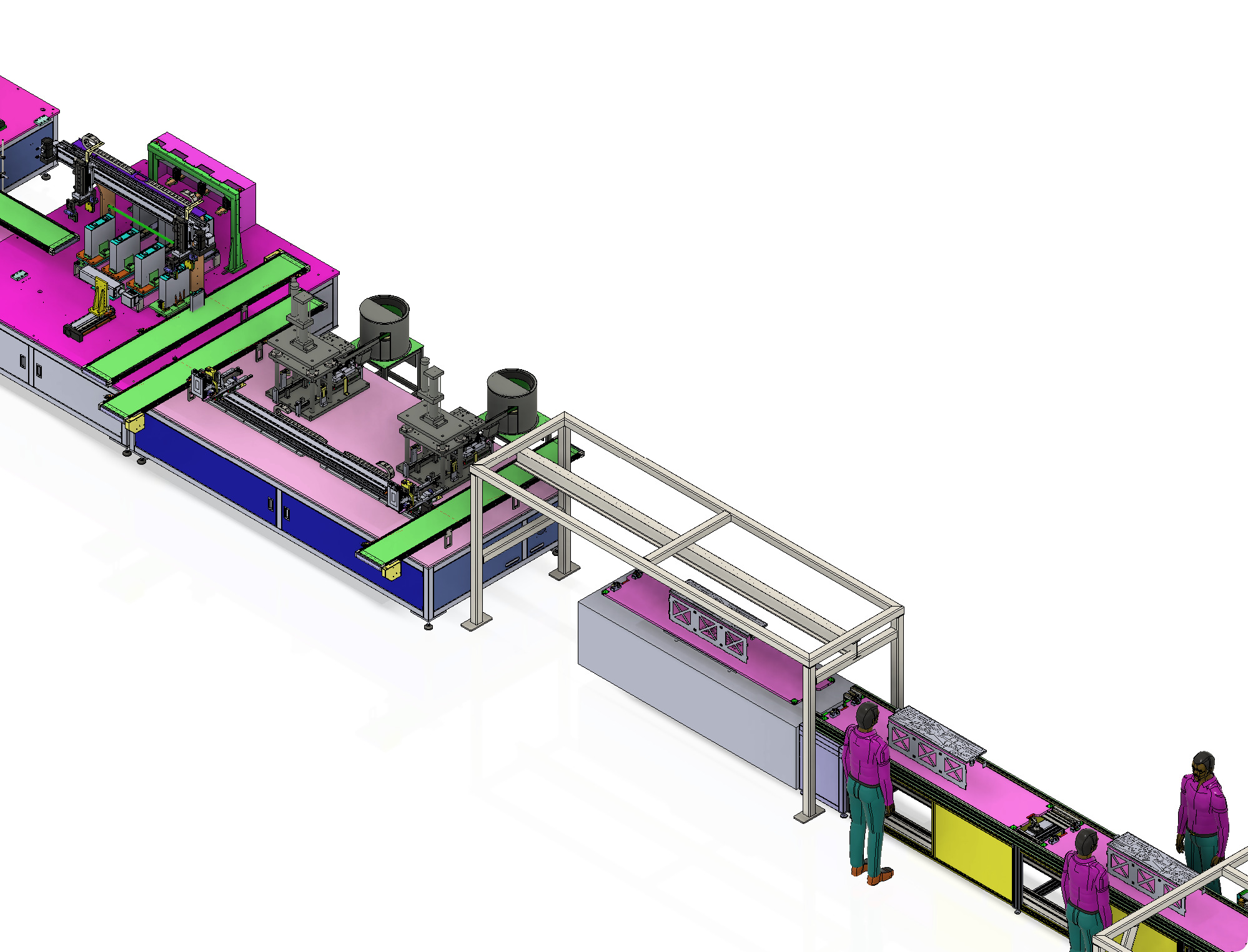

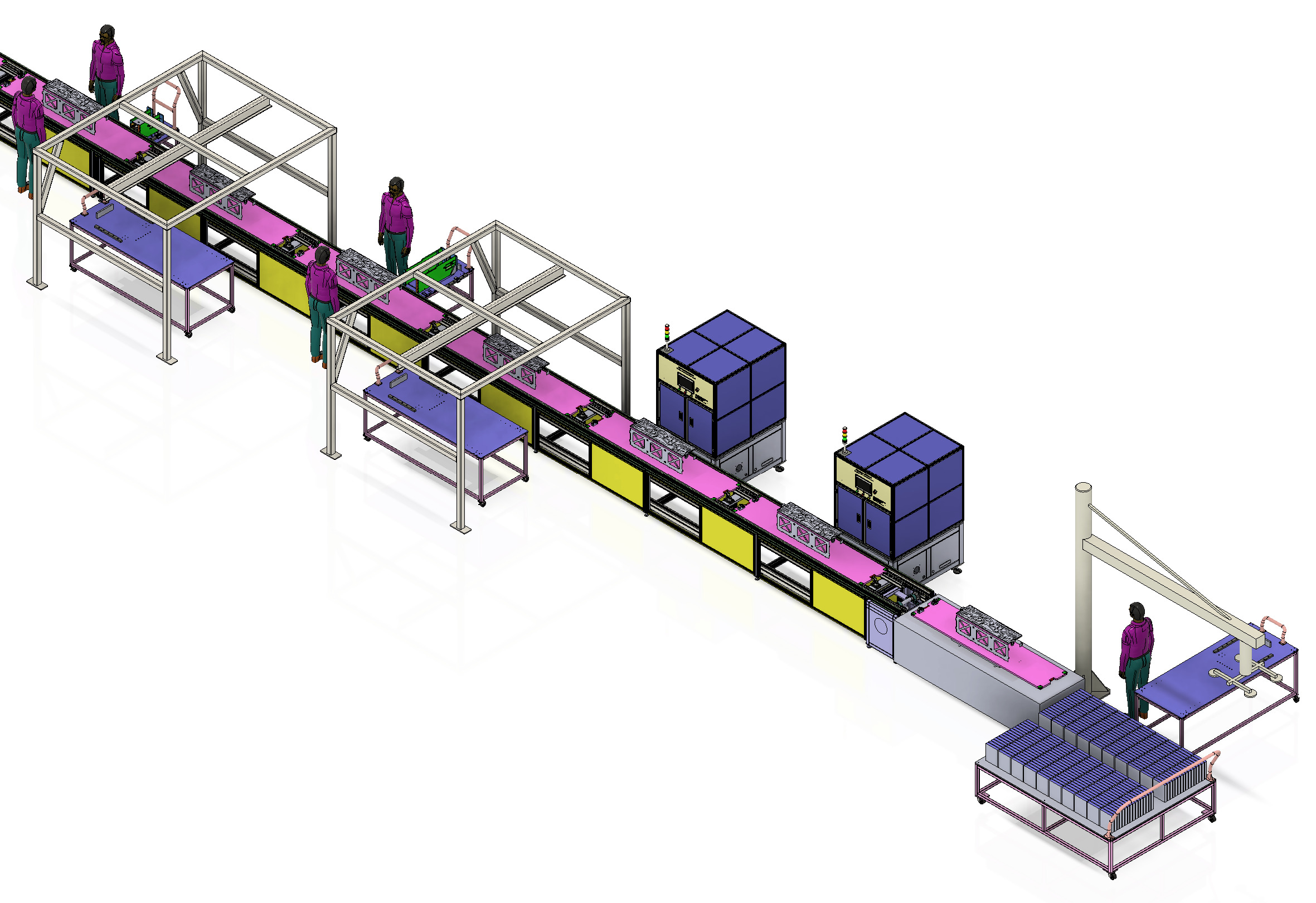

3D Model Design of Soft Pack Power Battery Assembly PACK Line 3D model

The 3D model design for the fully automated production line of soft-pack batteries for new energy vehicle (NEV) packs represents a pioneering advancement in the automotive industry. This intricate design leverages cutting-edge CAD technology to meticulously map out every stage from raw material handling to final assembly. It encompasses automated feeding systems, precision laser welding stations, high-efficiency electrolyte injection processes, and state-of-the-art quality control mechanisms, all seamlessly integrated within a compact, ergonomic layout. The model ensures optimal workflow, minimizing human intervention while maximizing throughput and product consistency.

The design also emphasizes sustainability, incorporating energy-efficient machinery and waste reduction strategies. This holistic approach not only elevates production efficiency but also underscores a commitment to environmental responsibility, paving the way for the future of eco-friendly automotive manufacturing.

This 3D model was designed by SolidWorks 2017, the file totaling is 2 GB, including step files for other 3D software to open.