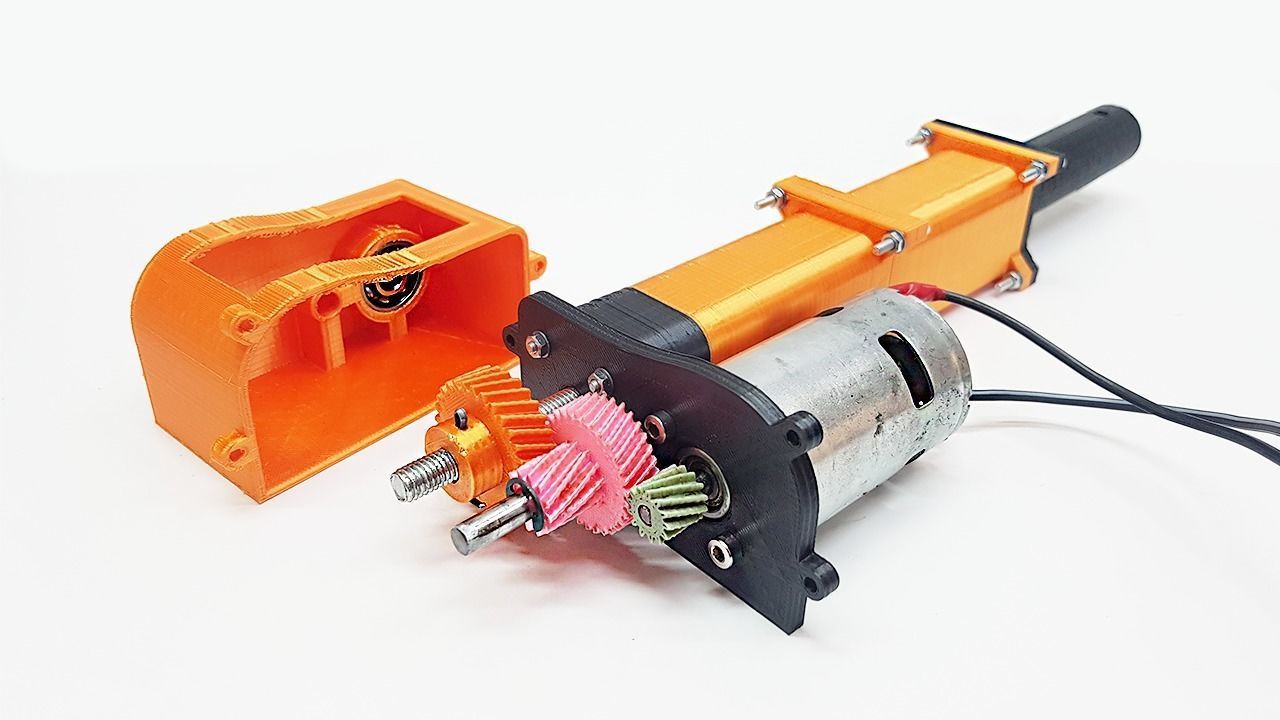

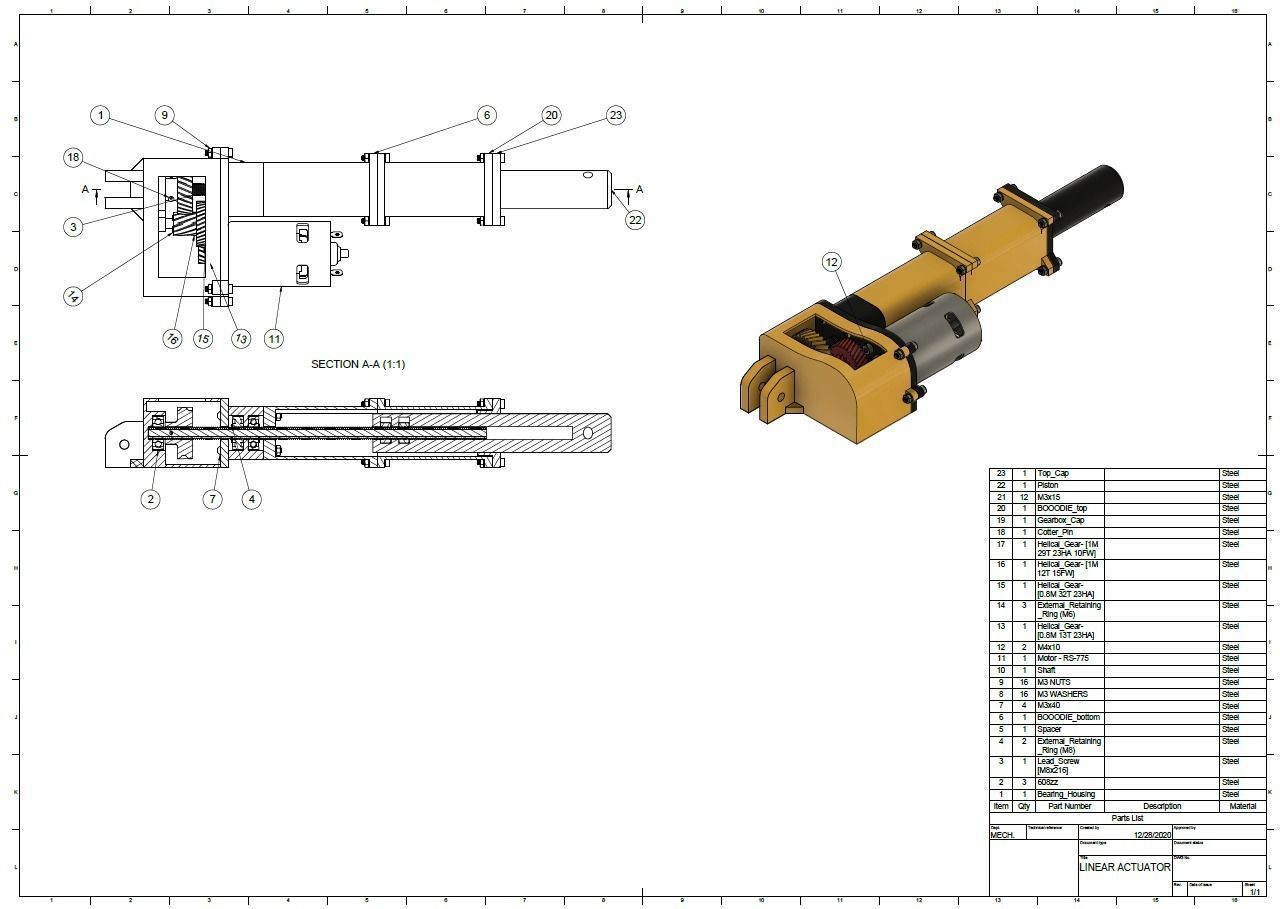

3D printable Linear Actuator 3D print model

Hi,I designed this linear actuator. You can print these parts with 3d printer and it's works harmoniously. You know this things provides a linear movement. I used 775 motor (100 watt) and I get a cool results. So the maximum axial load theoritically 250 Newton(~25 kg or ~ 56 lb). But if you use 775 motor which is one of 150 watt, this time axial load will theoritically 380 Newton (~38 kg or ~ 85 lb). The Piston stroke is 120 mm and piston speed about 30 mm/s. So 4 sec to required to full stroke. There is a small gearbox in the system. It has a 6 gear ratio. I used helical gears and they have m=0.8 mm and m=1 mm normal modules. The threaded rod is 8 mm diameter (M8) and the shaft of second stage has a 6 mm diameter. Nuts also M8. I used three 608zz ball bearings for support to threaded rod. If you make this project, The body does not need to be so strong. Because the body only meets the friction force between the lead screw and the nut. So you can print with %20 infill and 0.2 mm layer height for stationary parts.You should print the gears with lower layer height (0.12 mm -0.16 mm). Infill for the gears its good % 50 or %100

Part list• 775 motor-100W (You should use 150 watt) • 3-position rocker switch• M8 threaded rod (l=220mm)• M6 shaft steel shaft • 608zz bearing --- x3• M3x40 screw --- x4• M3X15 screw --- x12• M3 washers --- x16• M3 nuts --- x16• M4x10 --- x2 (for motor mounting)• External Retaining Ring (M8) x 2• External Retaining Ring (M6) x 2• Cotter pin (M2)

Any questions, im here for 7/24 !