1/27

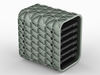

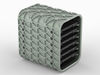

Make your own aerospace-inspired hard drive racks!

Inspired by the structural panels commonly found in both aircraft and spacecraft, these designs use a hybrid of orthogrid and isogrid patterning to connect all of the important nodes across the exterior of their shells and to create very robust and visually striking hard drive enclosures that feel like they came straight out of a satelite, a crew capsule, or a fighter jet.

Designs included are compatible with either 2.5in or 3.5in, SSD or HDD drives, and can hold either 4 or 6 drives.

In the download you will find multiple fine-meshed, ready-to-print STL files along with a bill of materials that specs all of the necessary ancillary components (with McMaster links) and provides some additional information pertinent to production and assembly. The 3.5in drive versions also include DWGs of the rear profiles for those looking to design their own end-caps that house a SATA controller, Raspberry PI, etc for enhanced drive monitoring / control, or full NAS functionality.

Just looking to get one of these? Find the other models by navigating to our profile. Check out our other models while you're at it!

Troubleshooting and Setup:

- If your slicer software doesn’t automatically interpret the correct units / scale try scaling by 25.4% (if it imports really small) or 0.0393701% (if it imports really big).

- We recommend printing face down for each model with a brim to help with bed adhesion.

3.5in Enclosures:

These were designed to be easy to print so feel free to mess around with the settings, use a larger nozzle and bump up the layer heights, print in a variety of different materials, or just go with whatever your slicer is set at default. Supports necessary. Be aware these can be long prints so without optimization, they could be on the bed for up to 100hours (for the large one). Make sure your settings preserve the overall shape however as not to change dimensions so that the ancillary components can still fit easily.

2.5in Enclosures

These are also designed to be easy to print. Same as above, we recommend printing with brims for better bed adhesion and simply slowing down the print to minimize the amount of vibration your printer will experience throughout the duration of the print.

2.5in Enclosures (Lightweight)

These are a bit more of a challenge to print but yield a surprisingly lightweight and strong part if printed successfully. Supports required, definitely tune your settings to make removal safe and easy, and we also recommend printing at a slower speed to minimize the amount of vibrations your printer will experience throughout the print.

REVIEWS & COMMENTS

accuracy, and usability.