ASSEMBLY WORKSHOP LINE FACTORY INDUSTRIAL PRODUCTION PACK 3D Model Collection

3D Model | .3ds | .dwg | .fbx | .obj | .3dm | .skp | .max | .blend | .ige | .igs | .iges | .stl | .mtl | .stp | .sat |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

THESE ARE SOME OF THE COLLECTIONS OF ASSEMBLY WORKSHOP LINE FACTORY INDUSTRIAL PRODUCTION PACK, THE PRICES ARE MUCH CHEAPER. !! LIMITED TIME PRICE OFFER !!!TOTAL : 5 ITEMThe model contains the most popular formats:

- 3DS MAX: *.max

- Blender: *.blend

- Rhinoceros: *.3dm

- SketchUp: *.skp

- Wavefront OBJ: *.obj *.mtl (Multi Format)

- FBX: *.fbx (Multi Format)

- STEP: *.step *.stp (NURBS)

- IGES: *.iges *.igs (NURBS)

- ACIS: *.sat (NURBS)

- 3DS MAX all ver.: *.3ds (Multi Format)

- Stereolithography: *.stl

- AutoCAD: *.dwg

- Each file was checked for opening and full content by the model.

- The 3D model was created on real base. It’s created accurately, in real units of measurement, qualitatively and maximally close to the original.

- Renders Are made in Luxion Keyshot

- “WE PROVIDE 3D MODEL CHEAP PRICE BUT WITH GOOD QUALITY”

- If you need any other formats we are more than happy to make them for you. Contact me for any question :)

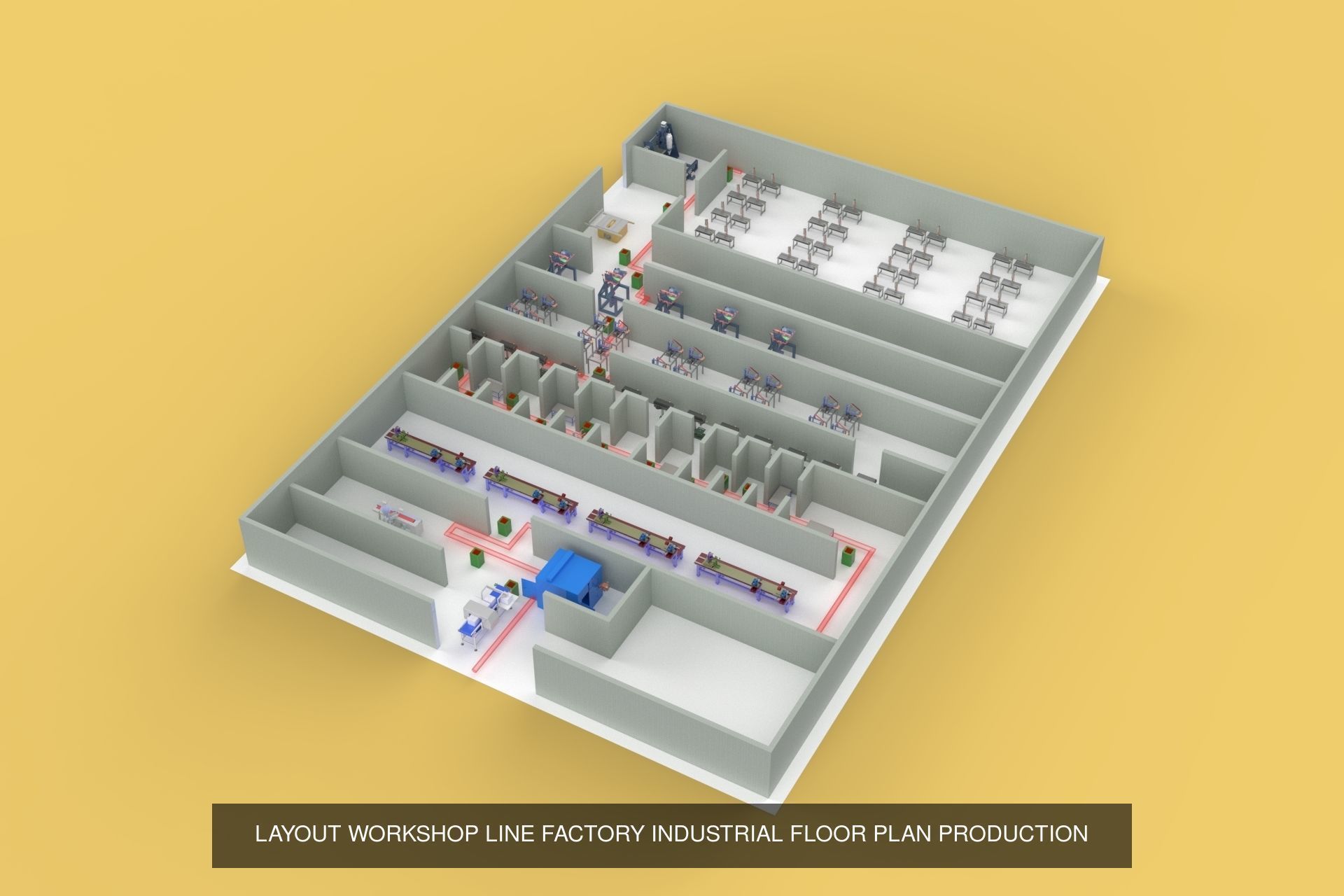

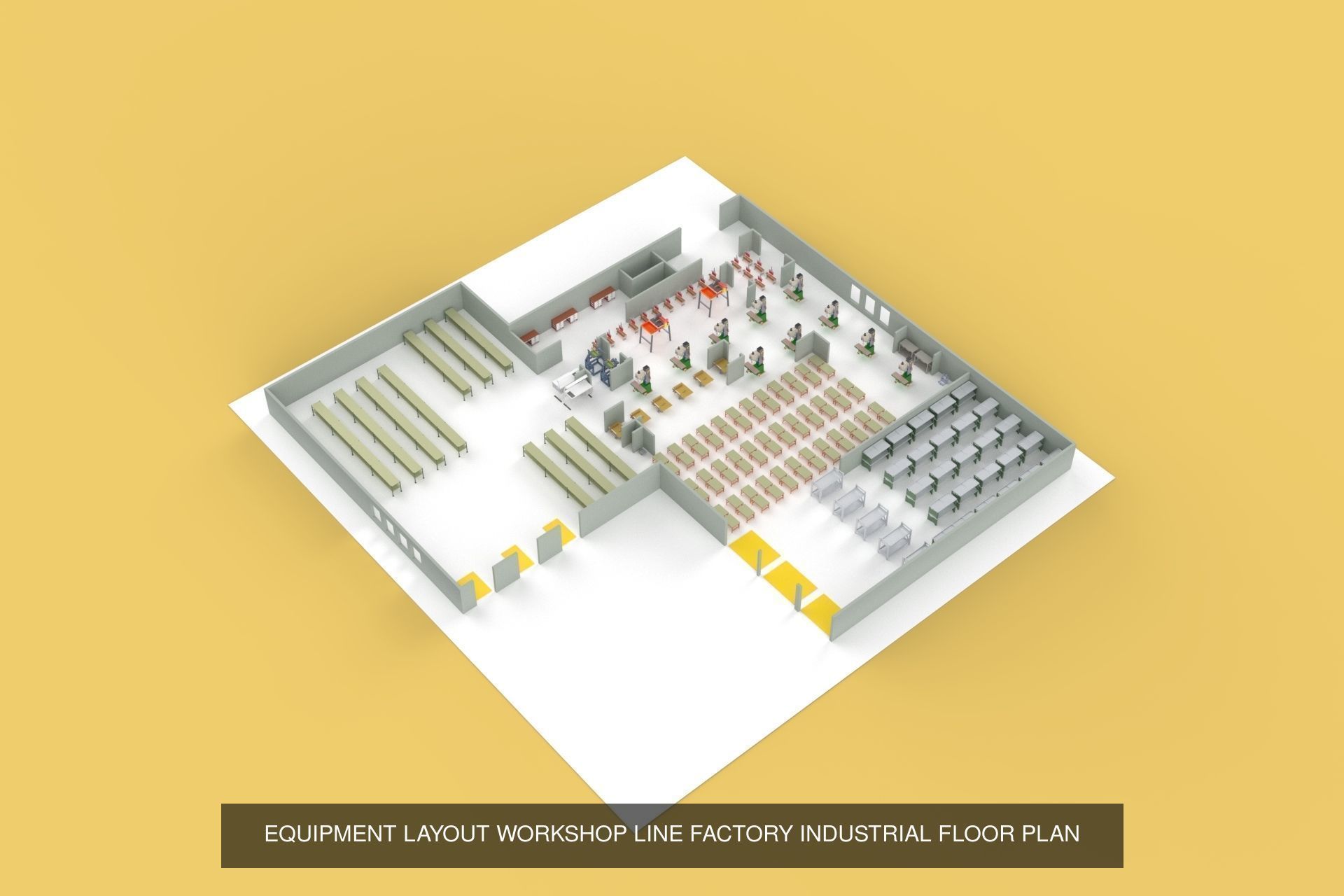

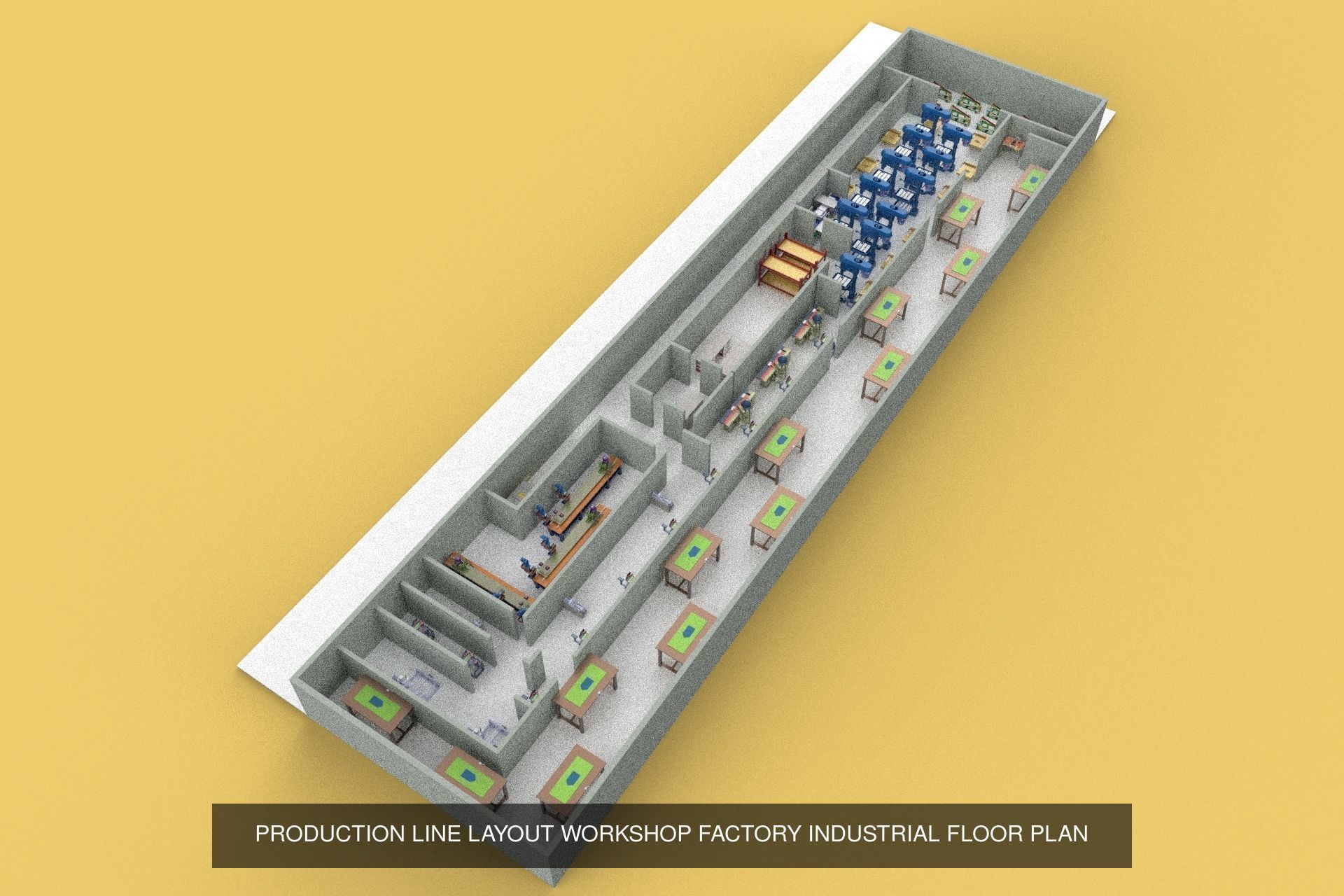

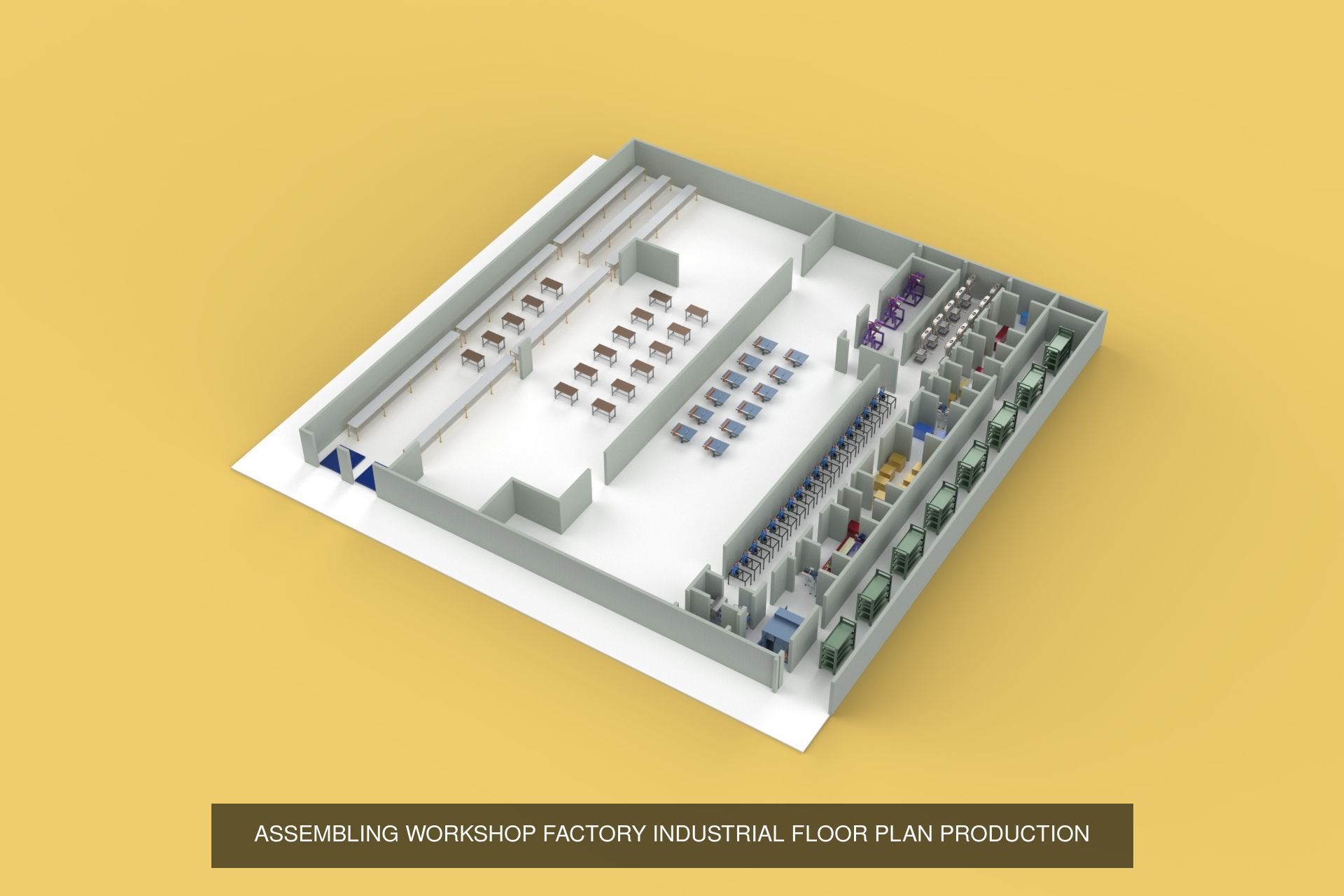

Sincerely Your, SURF3DMORE INFORMATION ABOUT 3D MODELS :A vast industrial building with a sturdy concrete floor marked for designated work zones and traffic lanes. Overhead, powerful lights illuminate the purposeful activity. Strategically placed windows offer glimpses of the outside world, a welcome contrast to the focused energy within.Production Line Symphony:

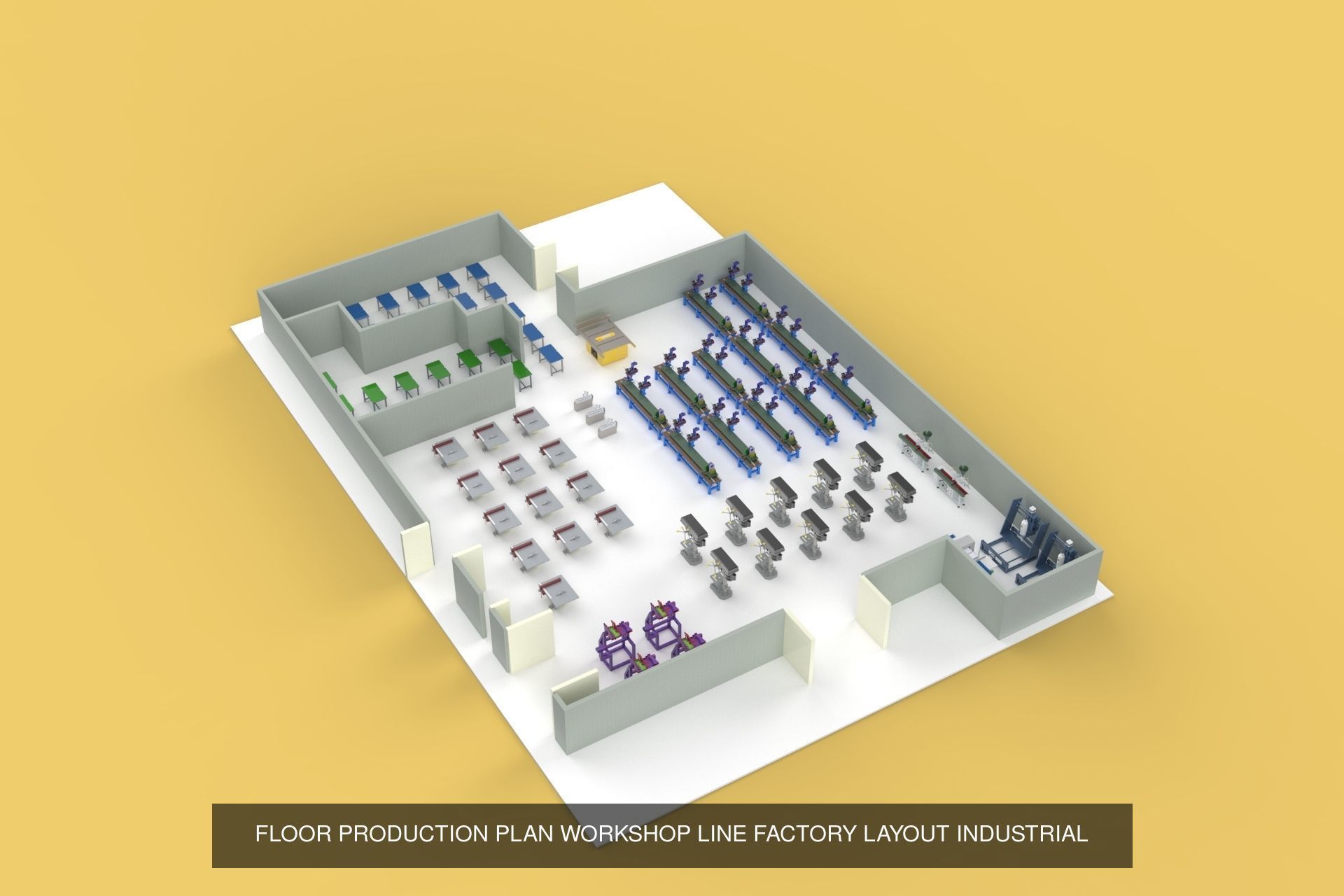

The central feature is the production line, a meticulously choreographed dance of transformation. It can be linear, snaking through the workshop, or U-shaped, maximizing space. A conveyor belt – sometimes metal, sometimes a webbed surface – acts as the stage, carrying materials or partially finished products from station to station.

Stations of Action: Each station, clearly marked and brightly lit, is an island of focused activity. Here, skilled workers, outfitted in appropriate safety gear, perform specific tasks with practiced precision. Tooling is meticulously organized, and parts feeders ensure a steady flow of components. Standardized work instructions, displayed prominently, keep everyone aligned.The Transformation Unfolds: At the beginning of the line, raw materials – perhaps sheets of metal, bolts and gears, or spools of raw materials – are meticulously staged. As the conveyor carries them forward, a series of transformations occur:Shaping and Forming: Machines may bend, cut, or mold the materials into specific shapes. Think of stamping machines or robotic arms wielding welding torches.Assembly and Integration: Workers or automated systems meticulously add components, following a set sequence. Think of intricate circuit boards being populated or car engines receiving essential parts.Quality Checks: At designated intervals, products undergo quality checks using specialized gauges or automated inspection systems. This ensures consistent quality throughout the process.Supporting the Flow:

Flanking the production line are designated areas for:

Sub-assembly stations: Here, smaller components are pre-assembled to expedite the main line's production speed. Think of pre-wiring electrical components or building sub-units of a larger product.Inventory management: Designated areas hold a buffer stock of parts to prevent line stoppages due to material shortages. Here, forklifts or automated guided vehicles (AGVs) might be in action.Equipment maintenance: A dedicated area houses spare parts and tools for technicians to maintain the machinery, ensuring smooth operation.The Guiding Force:

A central control room, the nerve center of the operation, monitors the entire line in real-time. Here, supervisors oversee production flow, identify bottlenecks, and make adjustments as needed. Large screens display data feeds, allowing for proactive problem-solving.The Overall Experience:

The production line workshop is a place of controlled chaos. The rhythmic hum of machinery mingles with the purposeful movements of workers. Visual cues, like flashing lights or digital displays, keep everyone informed. Despite its intensity, there's a sense of accomplishment as raw materials are transformed into finished products with impressive efficiency.

Remember, this is a generic description. The specifics of the workshop will vary depending on the industry and the product being manufactured. You might encounter advanced robotics in a car factory, while a food processing plant might feature specialized conveyors and temperature-controlled environments.